By Joel Bleth

There are more than 53,000 municipal water systems in the United States, and many of them rely on water towers and above- and below-ground storage tanks to store treated potable water. While drinking water treated with either chlorine or chloramines will normally remain stable and safe for a few days in storage, municipal water system operators have tended to rely on normal cycling of water in and out of the tank to keep the water mixed in order to limit aging and deterioration of disinfectant chemicals.

However, this reliance on "passive mixing" is often not enough to prevent thermal stratification that can lead to a drop in residual chlorine and the resultant growth of bacteria. When bacteria contamination occurs, a common practice is to drain and flush the tank, and refill it. This practice wastes water and raises costs for labor and chemicals.

New near-laminar-flow active mixing technologies have been developed to completely mix potable water storage tanks up to 100 million gallons, virtually eliminating sampling inconsistencies and thermal stratification. These technologies have the additional benefits of reducing labor and expenditures for chemicals, as well as providing a means for complying with EPA regulations.

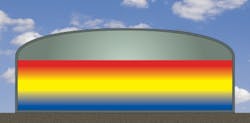

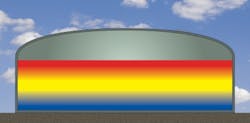

Thermal Stratification

Thermal stratification promotes deterioration of water quality, especially in the upper part of the tank. When water warms and stratifies, newly treated cold water coming into the tank may not mix well with the existing water, and tends to stay near the bottom. This cold water near the bottom is also the first to exit the tank, essentially short-circuiting or stranding the bulk of the warmer, stratified water above.

Thermal stratification can start to occur with temperature gradients as small as 0.1°C. If stratification persists for as little as five days, disinfection chemicals may begin to dissipate in the warmer, upper layers, allowing bacterial growth and an overall decrease in water quality.

Stratification also introduces sampling inconsistencies that can lead to over- or under-boosting of chemical disinfectant. Since water quality testing is based on sampling from selected locations within a tank, these testing points may not reflect the real health of the entire tank if it is stratified. However, having a fully mixed storage system provides a means for true sampling of water temperature and residual disinfectant from any sampling point.

Continuous Mixing

New solar-powered, near-laminar-flow continuous, active mixers were developed for solving water quality problems in lakes and raw water reservoirs and have the ability to circulate water out to a radius of 800 feet and to depths of more than 100 feet. They are also widely used to maintain water quality in potable storage tanks.

Instead of creating turbulence in the water, the near-laminar-flow mixer floats on top of the water and gently draws the water up from below. Exiting the mixer without turbulence, the surface water travels a long distance because it is essentially powered by gravity and experiences little resistance. This feature makes it possible to mix the water throughout the entire water column, from the bottom of the tank to the outer walls and everywhere in between.

While these mixers can circulate up to 10,000 gallons per minute, they require very little power due to the minimal head, or lift, in the up-flow pump design. This feature allows them to be driven by an electronically controlled DC motor that is significantly more efficient than induction motors typically used on turbulent mixers. The low-power requirement allows them to be powered by 80- to 300-watt solar photovoltaic arrays combined with a deep-cycle storage battery to allow 24/7 operation.

With the mixer floating in the water tank and a solar power source installed on the tank roof, the equipment can operate around the clock, completely mixing the tank to provide consistent disinfectant residual, and eliminate thermal stratification and deterioration.

Chloraminated Systems

While approximately 70 percent of municipal water systems use chlorine as their primary disinfectant, a growing number of municipal water agencies have switched from chlorine to chloramines as their disinfectant of choice. Continuous, active mixing is beneficial with both types of disinfectants, but is especially important in chloraminated systems.

If chloraminated water is allowed to age too long due to poor mixing, ammonia-oxidizing bacteria (AOB) may convert free ammonia to nitrites. As more and more water treatment facilities convert from chlorine to chloramines, the American Water Works Association (AWWA) has noted that nearly two-thirds or more of tanks with chloraminated water experience unwanted nitrification and a loss of residual disinfectant, especially when water temperatures rise during warm weather.

When the temperature of chloraminated water rises above 15°C (59°F), the AOB, which are 13 times more resistant to chlorine than most bacteria, begin to grow rapidly especially on the floor and walls of the tank. So it is critical that the mixing scheme circulates water along the walls and bottom of the tank and exposes AOB to disinfection chemicals.

Mixing can help with other water quality problems, too. In water systems with natural organic matter (NOM) content, chlorine added at the treatment facility will react with NOM to form disinfection byproducts called trihalomethanes (THMs). Formation of THMs is a concern because of potential health risks. The current limit is 80 ppb, but this will be lowered to 60 ppb over the next few years. As newly treated water flows into the tank from the water treatment plant, it tends to have its highest levels of THMs. In poorly mixed storage tanks, the new high-THM water tends to be the last in and first out, short-circuiting the older, stratified water above it. THMs naturally dissipate over time, so this older water usually has less THMs. By homogenizing the water in the tank, continuous, active mixing distributes and dilutes the THMs throughout the entire water column and minimizes the concentration of THMs in the effluent water.

Monitoring, Chlorine Boosting

While active mixing can provide consistent disinfectant residual, eliminate thermal stratification, and ensure that all of the water in the tank is of a uniform age, water quality still has to be monitored on a regular basis to ensure that it meets requirements. With active mixing, there will be much higher confidence in the sampling results due to the elimination of stratification. As a result, when testing reveals that the residual disinfectant level is low, the correct amount of chlorine can be added to boost the level of disinfectant. This prevents both over-chlorination (and higher costs) and under-chlorination. Provided that the tank is being actively mixed top to bottom and out to the side boundaries and back, water uniformity will be improved to the point where water testing results are consistent and, when needed, a simple boost of chlorine into the tank will often be effective in bringing the tank back to the desired water quality parameters.

About the Author: Joel Bleth, president and CEO, co-founded SolarBee Inc. in 1998. The company manufactures solar-powered long-distance water circulation equipment for potable water, wastewater, lakes and raw water reservoirs. SolarBee technology was originally developed by Pump Systems Inc., which Bleth co-founded in 1978. He was named North Dakota entrepreneur of the year in 2008 and holds a degree in industrial engineering from the University of North Dakota.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles