• Tested technology improves new biofuel processes

Membrane filtration technology, a tried and proven method used in many industrial process streams, is now being adopted in biofuels production and integrated biorefineries. In particular, membrane filtration technology shows promise to improve "second-generation" cellulosic ethanol processes. Operators of second generation processes seek to optimize fuel recovery and secondary products from the feedstock. In addition, these operators want to obtain a better value fuel than first-generation bioethanol processes, which focused exclusively on fuel production and simply disposed of everything else as waste or animal feed material. Koch Membrane Systems, Inc (KMS) Food and Life Sciences group is helping companies utilize membranes to improve bioprocesses, lower overall energy costs and increase valuable product recovery.

Membranes are highly engineered, physical barriers that are used in processes for liquid/liquid and liquid/solid separation. They permit the passage of materials only up to a certain size, shape or character. Membrane filtration has been used extensively in industry for years, especially in the dairy, sugar, food, starch, wine, and enzyme manufacturing sectors.

For example, membrane use is rising in biodiesel processes where membranes facilitate water reuse, particularly in areas where water is scarce. Membrane technology shows promise for making organic acids, commonly used as the base for a variety of new biodegradable plastics.

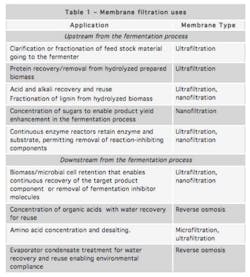

In addition, so-called integrated biorefineries are using a variety of membrane technologies, including microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Particular attention is being paid to using membrane filtration techniques that facilitate continuous, rather than batch, fermentation.

In the next few years, dozens of second generation cellulosic ethanol and integrated biorefinery pilot and demonstration plants will be placed online as the biofuel industry seeks to improve its processes before implementing full-scale production facilities.

Biofuels -- new generation hopes to optimize recovery to get better value

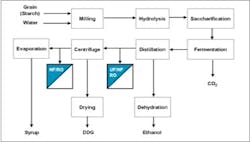

In the United States, the largest installed biofuel base is bioethanol, produced from starch-derived from corn and wheat material. The material is milled into small particles and the starch is broken down into a sugar solution, which is fermented, usually using yeast organisms, to produce bioethanol.

Enter the new generation of biofuel hopefuls. Spurred by concerns about the environmental impact of these early biofuels, as well as massive federal spending for energy-related research and development, "second-generation" biofuel developers are seeking to optimize the recovery process to get better value and reduce waste.

Makers of second generation cellulosic ethanol are taking corn stover (dried up cobs, and other waste products from agricultural land), and using enzymes and acid/alkali to extract fermentable material. They are converting cellulose to sugars, which are being fermented to produce alcohol. During the process, they are using a variety of membrane filtration techniques to improve recovery, reduce waste, and lower energy costs.

Because first-generation bioethanol facilities were focused on producing fuel rather than optimizing fuel recovery, there was very little use of or demand for membranes. With second-generation cellulosic bioethanol, a tremendous amount of work is going into using membrane filtration. For example, ultrafiltration is used for clarifying the process stream after turning it into sugars during the saccharification process.

Some processes use acid/alkali, and nanofiltration (NF) can be used to recover and concentrate some of the useful sugars like hemi-cellulose, which also is used in the fermentation process. Reverse osmosis (RO) is used for recovery of high quality water for reuse. Membrane filtration is also used for making organic acids as the base material for biodegradable plastic.

Figure 1 shows an example of how membranes can be used in the conventional grain (starch) based biofuel process.

How the time-tested membrane filtration technology is being adopted for future biofuels and integrated biorefineries• Ultrafiltration and microfiltration are used for biomass retention or fermentation broth clarification and product purification.

• Nanofiltration is used for low molecular weight component fractionation and desalting applications, where the process streams may have high concentrations of acids and base chemicals and organic solvents/water mixture.

• Reverse osmosis is used for product concentration and water recovery for reuse.

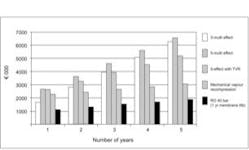

Using membrane technology has the potential to greatly reduce operating costs compared to the traditional method of using an evaporator to recover or remove water, which requires very high energy use.

Figure 2 shows a comparison of the economic benefits of membrane technology versus that of an evaporator. The example is based on first- and second-generation companies that use yeast to ferment sugars into ethanol.

One interesting development application driving the interest in membrane technology is its ability to operate at higher temperatures. Operators seek ways to run continuous fermentation, rather than a batch process. With a thermophilic process (micro-organisms, which display optimum activity around 70-78 degrees C), operators could continually run product and feedstock to the alcohol distillation columns. In that type of process, the membrane plays an important role as part of a membrane bioreactor, because it helps retain microbial biomass in the fermenter, while allowing liquid to be drawn out of fermenters continuously. This has the potential to reduce the hardware investment cost (by reducing the number of cyclic fermenters) and also reduce operating costs.

The next few years will see a great increase in demonstration plants working on continuous fermentation, and membranes are poised to play a significant role in this important advancement.

The wastewater issue in production of biogas and biodiesel

Membrane technology has long been used in wastewater treatment plants and it is now being used more and more in biodiesel production, which produces wash water very high in contaminants. In the past, facility operators could spread this waste stream on land or discharge it untreated to a wastewater treatment plant or local water source such as a river. Today, this is not permitted in many areas. In addition, water-constrained areas are trying to encourage water conservation and reuse rather than disposal.

In some cases, operators are using anaerobic digestion to remove Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) in the waste stream, installing UF membranes to concentrate the biosludge, and then using RO to recover water and reuse it in the facility. This is especially important in areas where water is limited. For example, Koch Membrane Systems' membrane filtration technology is being used as part of a membrane bioreactor at an Australian ethanol facility. Here, the waste streams go through biological treatment and use membranes to recover water for reuse.

Membrane technology part of wave of research and demonstration plants

A tremendous amount of government research and investment is being done on biofuels and integrated bio-refineries, much of it focused on increasing product recovery, reducing waste, lowering energy costs, and improving the greenhouse gas profile of biofuels.

According to 2009 data from the U.S. Department of Energy, 19 second-generation pilot and demonstration cellulosic bio-refinery facilities are either on the ground or in the works. These integrated biorefinery projects will receive up to $564 million for pilot, demonstration, and commercial scale facilities. Many of them are looking to gain the benefits of membrane technology. Pilot plant process development will feed into the demonstration plant installations.

Membrane technology has an opportunity to provide biofuel manufacturers with cost- effective solutions. New processes must be developed to take advantage of this promise, but they are building on successful membrane technology used effectively for years in other starch and sugar-based industries. While new to biofuel developers, using membranes for filtration and separation has been around for years. Membrane technology has great potential for providing significant benefits as developers improve their processes in preparation for integrating future process scale and production facilities.

WaterWorld Online - October 2010

###