Plants Meets Tougher Rules with New Filters, Disinfection System

By Steve Erler

Located in the idyllic town of Idyllwild, Calif., in the San Jacinto Mountains, Fern Valley Water District has been a trusted source of clean water since its inception. Throughout the year the characteristics of the raw water supply change due to weather. This causes high turbidities and increased coliform densities usually following heavy rainfall events. More changes come during warm spring weather which causes rapid melting of local winter snow pack, and summer low water flow when the creeks nearly dry up.

Committed to quality, the district has successfully served a community of 900, reaching a seasonal maximum population of 2,300 people, for 52 years. Recently, after a change in regulations for drinking water filtration by the Environmental Protection Agency, Fern Valley was faced with the job of quickly updating their facility.

In January of 2005, new standards for small water treatment facilities were put into effect by the EPA which caused Fern Valley's satisfactory treatment plant to fall out of compliance. The new Long Term 1 Enhanced Surface Water Treatment Rule (LT1ESWTR) required at least a 2-log removal for Cryptosporidium for any water system providing for less than 10,000 persons.

With a 1.5 log removal for Cryptosporidium, the district's water system was now slightly below the new requirement. As a result, the district undertook the task of finding a new treatment system to best meet the new standards.

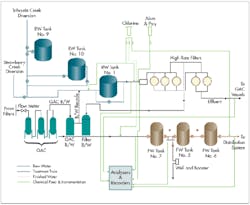

The district decided to completely replace its existing water treatment system with new equipment that could ensure compliance with the new regulations. This would mean replacing all present multimedia filters, cartridge filters, and bag filters within the district's facility. To do this, Fern Valley representatives visited locations with current filtration systems approved by the EPA in relation to the new LT1ESWTR. After much consideration, the district determined that a high rate permanent media filtration system from EPD USA Inc. would be the best and most effective solution.

The selected EPD filters use EPA approved filtration technology for surface water treatment. The system meets the 2-log removal requirement for Cryptosporidium along with removal credits of 2-log for Giardia and 1-log for Viruses. With the addition of a new disinfection process, which must provide a 1-log inactivation of Giardia and 3-log inactivation of viruses, the entire plant would meet the requirement stated in LT1ESWTR.

The new system includes two main stages of operation. Each EPD filter unit vessel offers 16.5 square feet of surface area, is constructed of 50 PSI steel, and is polyethylene lined. Stage 1 allows a filter loading rate of 6 gpm/sq.ft., consists of three parallel filters, and yields a flow rate of 300 gpm. Stage 2 allows a filter loading rate of 9 gpm/sq.ft., consists of two parallel filters, and also yields a maximum flow rate of 300 gpm.

Each filter uses a single size media. The first stage filter uses 50x garnet (.27 mm) and the second stage filter uses 60/80x garnet (.15mm). The system has automatic backwash capability, as well as turbidimeter and chlorine analyzer-controlled alarm callout and shutdown functions. The district alternates stage 1 and stage 2 backwashes weekly. The water is discharged into two, 2,750-gallon polyethylene storage tanks. The stored water is decanted and a portion sent back to tank 1 where it is blended with raw water from the creeks. Throughout the entire filtration process the only chemical addition required is aluminum sulfate.

The new filters and the new chlorination equipment work in concert to achieve a more efficient chlorination method that reduces prechlorination in the raw water tank. The system also allows for chlorine CT requirements to be met in the finished water tank.

The upgrade included a Chlor-Tec on-site generator capable of producing 12 pounds per day of 8% sodium hypochlorite. The system consists of salt storage, water softeners, brine tank, 500 gallon day tank, and three VFD feed pumps (12 gph). Pump #1 provides 0.2-0.5 mg/l to the plant influent, Pump #2 provides 1.0-1.5 mg/l to Tank 7 influent (CT tank), and Pump #3 provides 0.5-1.5 mg/l to water entering the distribution system. All pumps are controlled via chlorine residual feed-back loop from the chlorine analyzer.

The typical daily production during peak tourist season is 300,000 + gal/day (depending on diversion and raw water capacity). Daily production during the off season is 115,000 gal/day. The plant has a nominal capacity of 300 gpm plus room for expansion to 400 gpm.

After 4 years of continuous use, the EPD system at Fern Valley Water District is performing just as efficiently as the day it was installed. WW

About the Author: Steve Erler has been General Manager of Fern Valley Water District for 12 years. He also resides in Idyllwild which is part of the Fern Valley community.More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles