Dec. 9, 2010 -- The Analytical Laboratories of AMERICAN Cast Iron Pipe Company, known in the metal casting industry for their role in the development of iron and steel standards, is celebrating its 100th anniversary. The five laboratories, under AMERICAN's Quality Assurance Division, deliver real-time, high quality data to production units as part of the company's quality control and environmental compliance.

"The Analytical Labs work behind the scenes to give production units the real-time data they need to adjust the variables in their processes so that the end product is what the customer has specified," said Quality Assurance Division Director Frank Pausic. "Our in-house analytical capabilities are impressive, and we are committed to keeping them strong."

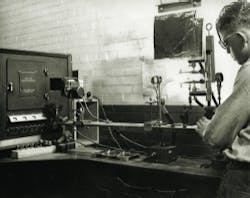

From the 1940s through the 1980s, the company was a regular contributor of metal and analysis for the National Bureau of Standards' (NBS) certified reference materials. These were pieces of metal with chemistry verified and certified by multiple labs that were used as standards for calibrating spectrometers and other instruments throughout the metals industry.

The Spectrographic Lab (also called Spec Lab) uses an optical emission spectrometer to analyze the chemical composition of iron from AMERICAN's two furnaces, the cupola and the Contiarc. "We sample for 15 key elements at numerous points between the initial melt stream and the production ladle, just before it is poured into a casting machine," Hayes said.

The Spec Lab also analyzes samples of purchased steel, or skelp, to verify chemical properties against the supplier's records. "This lab runs about 350 samples per day, most of which are for the production of ductile iron pipe," Hayes said.

The Carbon Sulfur Lab uses an instrument that oxidizes the carbon and sulfur in iron and steel samples to make it detectable in infrared cells.

The Sand Lab provides data on sand grain size, clay-sand mixture strength and other properties important to iron casting. It also analyzes sand-to-cement ratios in ductile iron pipe lining mixtures and documents lining compliance with American Water Works Association standards. The asphalt used in pipe coatings is analyzed for desired properties and environmental compliance.

Liquid samples, such as those taken from the plant water recirculation and cooling systems, are analyzed in the Environmental Lab. "Here, we analyze samples for elements such as lead, cadmium, zinc and copper," Hayes said. "The Environmental Lab works closely with Environmental Engineering to report all elements tracked by governmental authorities."

AMERICAN Cast Iron Pipe Company, founded in Birmingham, Alabama, in 1905, is a manufacturer of ductile iron pipe, spiral-welded steel pipe, fire hydrants and valves for the waterworks industry and electric-resistance welded steel pipe for the oil and gas industry. AMERICAN's diversified product line also includes static castings and high-performance fire pumps.

Web: www.american-usa.com

###