Utility Begins Work on 240 mgd UV Disinfection Facility

By David J. Opferman, Marco Aieta, Ramesh Kashinkunti and Jason Fleming

The Greater Cincinnati Water Works (GCWW) has a long history of leadership and innovation in the drinking water industry. To continue that tradition, embrace advanced treatment technology and improve public health, a significant advancement is currently underway at GCWW's Richard Miller Treatment Plant (RMTP), where a new ultraviolet (UV) disinfection system is being constructed.

GCWW supplies approximately 1 billion gallons of water per year to more than 1 million consumers in the greater Cincinnati area. The majority of this water is produced at the RMTP, which has a treatment capacity of 240 mgd and treats an average flow of 126 mgd. The RMTP is a conventional surface water treatment plant that draws its raw water from the Ohio River. Its treatment process train includes conventional pretreatment (rapid mixing, flocculation and lamella plate clarification), sand filtration and granular activated carbon (GAC) adsorption contactors. The GAC contactors use 11.5 feet of granular activated carbon and provide 15 minutes of empty bed contact time. Chlorination applied after the GAC contactors meets primary disinfection requirements for Giardia and virus inactivation, but is ineffective against Cryptosporidium - a chlorine-resistant pathogen now regulated under the Long-Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR).

The finished water produced by the RMTP is of excellent quality and meets or exceeds all current drinking water standards (including LT2ESWTR requirements for Cryptosporidium). However, the plant's Ohio River water source has the potential to be affected by municipal wastewater discharges, combined and sanitary sewer overflows, and urban and agricultural storm water runoff. Given these factors, additional treatment requirements for Cryptosporidium or other emerging pathogens may be required in the future.

To address these treatment challenges, GCWW is constructing a 240-mgd, post-GAC UV disinfection facility at RMTP. This facility will provide an additional disinfection barrier and enhanced protection against a wide range of microbial contaminants from the Ohio River watershed. It will also ensure compliance with the LT2ESWTR, regardless of bin classification and related treatment requirements. (Under the rule, filtered water systems will be classified in one of four treatment categories (bins) based on the amount of Cryptosporidium in their water supply).

Consistent with GCWW's history of proactive treatment improvements, the UV system is being voluntarily installed as a non-regulatory driven initiative.

Planning and Design

Planning and design of the UV Disinfection Facility Project was executed in three phases. GCWW began evaluating UV process upgrades in 2000 with the Phase 1 UV Feasibility Study, which assessed UV disinfection effectiveness for emerging pathogens in a bench-scale collimated beam study. Sequential treatment using UV and free chlorine was evaluated for multiple target pathogens, including Cryptosporidium oocysts, Bacillus subtilis spores, E. coli, MS2 coliphages, PRD1 phage, adenovirus, mycobacterium, and Toxoplasma gondii oocysts. Other investigations included chlorinated DBP formation after UV treatment and the effect of UV disinfection on microbial regrowth in the distribution system.

The Phase 2 Pre-Design Study, completed in 2004, identified post-GAC as the optimal UV process train location, and analyzed its hydraulic grade line profile. Field tests and hydraulic measurements determined that approximately 6 feet of head was available between the GAC contactors and the finished water clearwells. Computational fluid dynamics (CFD) modeling was conducted on various reactor combinations to predict headloss through the reactors and associated upstream/downstream piping. The analysis determined that sufficient hydraulic head was available to install either medium-pressure or low-pressure high-output UV systems within the existing process train without pumping.

For Phase 3, GCWW looked to partner with a consultant team to complete the planning and design of the UV facility. In 2006, CDM, in partnership with Carollo Engineers, was awarded a contract to provide engineering planning, design and construction services for the new UV disinfection facility. The team also included RA Consultants, a local Cincinnati civil engineering consulting firm. During Phase 3, GCWW and the CDM-Carollo team conducted process engineering, preliminary design, a UV/AOP taste and odor study, a UV/AOP pilot study, UV equipment procurement and detailed design of the UV facility and related improvements.

Designing a state-of-the-art UV disinfection facility, and ensuring its reliability and flexibility, was possible thanks to the successful collaborative relationship between CDM, Carollo, RA Consultants and GCWW.

Early in the project, the CDM-Carollo team used CFD modeling and UV system simulation software (UVCAT) to evaluate and optimize UV system design concepts. The analysis considered the enhanced disinfection of emerging pathogens and the application of UV light with hydrogen peroxide for the reduction of organic micro-pollutants. The analysis provided a clear understanding of the key design issues impacting successful implementation of the project, including reactor size, number of reactors, disinfection target and variations in UV transmittance.

The team also used the U.S. Environmental Protection Agency's (EPA) public health risk assessment model to quantify the project's public health benefits. Results indicated that implementing UV disinfection at the RMTP would reduce public health risks associated with Cryptosporidium to less than 1 infection per 100,000 persons. This result is expected to save $700,000 to $1 million per year in public health avoidance costs.

The UV equipment was selected during the design phase of the project using a competitive equipment procurement effort. Equipment procurement documents (drawing and specifications) for both low-pressure and medium-pressure systems were developed. A life cycle-based selection approach was used to compare the bids received, taking into account capital costs and life-cycle costs, including those associated with power and lamp replacement. Based on the evaluation, medium-pressure UV reactors from Calgon Carbon Corp. were selected. Procuring the equipment during the design phase allowed the design of the UV facility to be tailored to the selected medium-pressure technology.

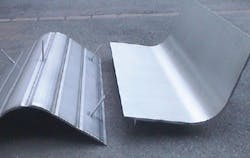

The selected design consists of eight Calgon Carbon Sentinel® 48" Chevron reactors. Each UV reactor train will be rated at 35 mgd, for a total firm capacity of 245 mgd with seven duty trains and one standby train. Each reactor will house five 20-kilowatt (kW) medium-pressure lamps. The Sentinel® system will provide UV disinfection of a wide range of waterborne pathogens, including Cryptosporidium and Giardia, using high-intensity, medium-pressure lamp technology. The system is designed for a disinfection target of 99.99% Cryptosporidium inactivation-the highest disinfection credit allowed under federal drinking water regulations.

The UV system will be housed in a new building that provides approximately 19,600 square feet of space across two levels. The reactors will be housed on the lower level, with electrical and other support spaces situated on the upper level. The building will be initially outfitted with eight UV trains, but it is sized to accommodate two additional future trains, for a total of 10 trains.

To help offset the increased energy demand of the UV treatment process, GCWW will also install solar panels on the roof of the UV Facility. The system will include 160 solar panels capable of generating approximately 45 kW of electricity, which, in combination with other GCWW solar installations, is enough to meet the majority of the power needed by the UV system under average daily flow conditions. Renewable Energy Credits provided by the local electric supplier will further help offset the operational costs of the UV facility.

In the future, GCWW will have the option to supplement this enhanced disinfection process with a UV/peroxide advanced oxidation process (AOP) for removal of emerging chemical contaminants, as well as taste- and odor-causing compounds. The UV facility was designed with features that will facilitate a conversion to the AOP process if this is ever needed.

Phase 3 was completed in July 2010, when bids for the construction of the UV facility were received. A $20.3 million construction contract was awarded to Adams Robinson Enterprises of Dayton, OH.

Construction

Phase 4 of the project is ongoing, and involves the construction, start-up and commissioning of the UV facility. Construction began in September 2010 and is anticipated to be complete in December 2012. The CDM-Carollo team is providing engineering services during construction. When completed, this UV disinfection system will be one of the largest UV disinfection drinking water facilities in North America, and it will significantly improve public health protection for Cincinnati's water supply customers.

WW

About the Authors: David Opferman, P.E., is a project manager with CDM's Columbus, OH, office who focuses on the planning, design and construction of water supply, treatment and distribution facilities. Dr. Marco Aieta, director of Water Practice for Carollo Engineers, leads Carollo in the planning and implementation of water projects, including developing strategies to help clients achieve cost effective solutions, realize water quality goals, comply with current and future regulations and gain public acceptance. Ramesh Kashinkunti, P.E., is a supervising engineer with GCWW's water quality and treatment division. Jason Fleming, P.E., is a supervising engineer with GCWW's engineering division.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles