Driving Down Non-Revenue Water in Ploesti, Romania

Reducing heavy water losses requires numerous initiatives, with pressure management now seen as an essential tool for leakage management. Here's how a city in Romania managed to reduce water losses by 20% from installing new technology and reducing pressure at night.

Leakages can cost water companies much more than the water lost from the distribution system. Water companies continue to dedicate significant resources to resolve issues related to non-revenue water (NRW); water that is "lost" it reaches the customer.

Reducing leakage and water loss requires initiatives such as increasing the speed of leakage detection, optimising asset management and not least by designing a pressure management strategy. The latter is now well recognised as being essential to effective leakage management.

The benefits of reducing and controlling NRW and leakage reduction in particular include financial gains from the increased amount of water reaching the customer, effectively meaning a reduction in water production. This includes the possible delay of costly capacity expansion, the increased knowledge about the distribution system gained in the process, and the reduced risk of damage and contamination.

An important contributing factor behind new leaks is "water hammer". Caused by sudden momentum changes in a pipe system, this phenomenon can be reduced or eliminated by lowering fluid velocities, gradual pump ramp-up/ramp-down or reducing pump size, for example.

Case study - Ploesti, Romania

The Ploesti Nord Gageni zone, in the city of Ploesti, just 60 km from Romania's capital Bucharest, was suffering from Non-Revenue Water (NRW) losses of 30%, losing 1.5 million m3 per year. Supplies reached 60,000 consumers in 13,000 households, with the weekly pumped volume approximately 100,000 m3 per week, or 5 million m3 per year. Pump pressure was 2.9 Bar during the day and 2.6 Bar at night.

Over the previous two years, Apa Nova and Veolia Water had invested in new Horizontal Splitcase HS pumps with Control MPC-EF for the Ploesti Nord Gageni pumping station. In addition, repairs to pipes in the network had also been carried out.

Following this period of new investment with various flow reduction and energy saving measures, the owners of the Ploesti Nord Gageni pumping station agreed to implement a Grundfos Demand Driven Distribution proportional pressure management solution, in an attempt to gain even greater reductions in energy consumption and NRW. To accomplish this, a basis for comparison needed to be made.

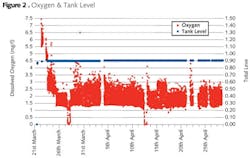

Flow and energy consumption were monitored for varying periods on two occasions in the second half of 2010. The reason for two periods of monitoring was the unforeseen consequences of seasonal variations in air temperature.

The first period of monitoring was in August and September 2010 and covered the following situations: constant pressure at 2.9 Bar during the day and reducing the pressure to 2.6 Bar at nights (between midnight and 6 am) and constant pressure 2.9 Bar 24 h/day.

As expected, when the existing constant pressure model with reduced pressure at night was compared with the results for the same pressure 24 hours a day, there were savings on water flow. However, simply reducing the pressure during night time did not provide a significant benefit of reduced energy consumption, because during night time the pumps operate at low flow and consequently have a low energy consumption at any pressure.

The second period of monitoring was in October 2010 and covered the situations of Constant pressure 2.9 Bar and Demand Driven Distribution. Comparing the existing constant pressure model with a Grundfos Demand Driven Distribution model showed that a pressure management system generated substantially higher savings for energy consumption and reductions in leakage loss.

Ploesti Nord Gageni had reduced water losses from 50% to 30% over the last 10 years, by installing new pumps, replacing pipes and dropping pressure at nights.

"Following our efforts over the years to reduce leakage and energy consumption, we didn't really expect we could achieve substantial further savings," says Alina Mihalache, directeur exploitation, Apa Nova Ploesti, Veolia Apa.

A further reduction of water loss of almost 7% was achieved by using Demand Driven Distribution, and the substantial energy savings accrued when the pumps run flexibly - according to consumer demand - proved to be over 7%.

Calculating the calculations

Energy savings are based on the measured specific energy (kWh/m3) from the test periods outlined above. Savings on reduced NRW are calculated from accepted international calculations of leakage rates and estimated reductions, using FAVAD (Fixed and Variable Area Discharges) methodology, developed by the International Water Association.

FAVAD equations are able to take account of pressure and flow, even where precise figures are not available due to insufficient knowledge of the network. These calculations are based on the following assumptions:

• The number of connections

• Legitimate consumption, meaning the expected consumption in the given population i.e. number of households multiplied with the expected average night consumption

• Exceptional users, meaning known users that exceed the legitimate flow

• Minimum night flow, averaged over one hour, based on 15 minutes samplings between 3 am and 4 am.

For the Ploesti Nord Gageni zone calculations, the following equation was applied: NRW (Leakage) = Minimum Night Flow - (Exceptional User + Legitimate Consumption). Leakage rates and possible reductions are calculated from estimated yearly flow, based on the figures from the test periods outlined above.

Results and benefits

The following are the percentage deviations for Annual Energy Consumption and Total Leakage according to FAVAD. Percentage deviations are shown for, respectively, running at constant pressure with reduced flow at night and for constant pressure 24 hours per day.

Results from test 1 – Constant Pressure versus night time duty:

• Night time lowering of pressure reduced NRW (leakage) losses by 2.5%

• Night time lowering of pressure reduced specific energy (kWh/m3) by 3%.

Results from test 2 – Constant Pressure versus Demand Driven Distribution:

• Demand Driven Distribution reduced NRW (leakage) losses by 6.6% ≈ 146,000 m3/year.

• Demand Driven Distribution reduced Specific Energy (kWh/m3) by 7.4% ≈ 48,000 kWh/year.

Reducing pressure at night resulted in reductions in NRW (leakage) losses and energy consumption, when compared to Constant Pressure (Test 1). Furthermore, Demand Driven Distribution doubled the reductions for both measurements, when compared with Constant Pressure (Test 2).

Over the previous couple of years, Ploesti Nord Gageni had already upgraded with Grundfos pumps and MPC controller. The task was to upgrade the control unit further to the latest version, and to implement Grundfos Remote Management (GRM), which enables communication, remote monitoring and control. For other installations, the best solution may be a new Control MPC – or even a completely new pumping solution.

Energy and Water Savings

Following the test and depoyment of the new system, Ploesti Nord Gageni now manages to save:

> 50,000 kW/h energy per year

> 150,000 m3 water reduced leakages per year

The next step for Ploesti

The Demand Driven Distribution is easily installed at the waterworks or pumping station and helps reduce costs and limit water loss in a water distribution system by effective pressure control. This is done by compensating for surplus pressure in the pipe system and by reducing water hammer which causes new leakages.

The Demand Driven Distribution operation can be further optimised by means of sensors in the pipe network, for example using pumps with Grundfos' AutoAdapt technology. Changing from one Duty Pump to two to three smaller Duty Pumps would also have a beneficial effect, as would a general lowering of system pressure and introduction of discrete boosters.

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles