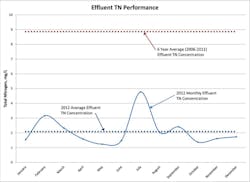

NORTH CAROLINA, OCTOBER 24, 2016 -- By upgrading its oxidation ditches, an Eastern North Carolina plant saw a reduction of 76% TN compared to its average discharge from the past 6 years.

The Client

This 0.63 MGD wastewater facility, in Eastern North Carolina, operates under a NPDES permit and discharges into the Neuse River basin, a Nutrient Sensitive Water (NSW) in North Carolina.

The Client’s Needs

To protect the sensitive waters of the Neuse River Basin, the State of North Carolina formally adopted a nutrient management strategy in 1997 which established Total Maximum Daily Loads for all point source contributors of Total Nitrogen (TN) to the Neuse River. The Neuse River Compliance Association was also formed to provide monitoring and nutrient trading opportunities within the Neuse River Basin. As a discharger to the Neuse, this wastewater facility struggled for many years to meet its allocation of 7,096 lb./yr., and was required to lease nitrogen credits for six years at a cost of over $8 per lb. of nitrogen. Although the existing oxidation ditch system with rotary disc aerators was capable of providing some degree of denitrification, it could not produce the low effluent TN concentrations needed to meet its allocation.

The Solution

While the system provided adequate treatment volume and, if operated at optimum submergence, sufficient aeration capacity, the operational strategy and lack of independent mixing severely limited its potential. The consulting engineer and Kruger devised a solution to overcome these limitations, capitalizing on Kruger’s extensive experience with aerobic/anoxic cycling, online nutrient monitoring and process control. Kruger implemented independent mixing, which allows for the entire volume of each ditch to be operated in either aerobic or anoxic conditions, and offers a far superior level of flexibility and optimization than the original system concept. The system was then further optimized by providing flexible modes of operation with both time-based and nutrient-based methods of control.

The Benefits

• Substantial increase in total nitrogen removal

• Enhanced real-time knowledge of system characteristics

• Improved process flexibility

• Greater process control

Process Description

The system was upgraded with mechanical mixing for each oxidation ditch and an enhanced control system with pH, DO, NH3-N and NO3-N monitoring. DO and pH monitoring were achieved with in-situ probes, while the nutrient monitoring was achieved with Kruger’s Superior Tuning and Control (STAC) control system. STAC offers both MLE and AE-DENITRO™ modes of operation with aerobic/anoxic phasing control of each ditch based on time, DO and nutrient monitoring. In MLE mode, STAC also provides automatic MLSS recycle rate-control based on nutrient monitoring in the tanks. In addition to the new process equipment and control logic, Kruger provided a comprehensive guarantee of the process performance.

Results

The year when the upgrades were implemented marked the first year since 2004 that the facility was not required to lease nitrogen credits. In its first full year of operation of the upgraded system, the facility discharged an effluent TN load to the Neuse River of 2,376 lbs., representing an average TN concentration of 2.08 mg/L. This was a reduction of 76% compared to the average discharge from the previous 6 years, and brought the facility well within its TN allocation.www.veoliawatertech.com

RELATED ARTICLES

Veolia to supply effluent treatment facility for Pretium Resources Brucejack gold mine in Canada

Veolia strikes gold with water treatment contract renewal at Ghana mine

Veolia to provide wastewater treatment system for LACC ethane cracker and Lotte MEG plant