By Robin Kluck, Jaun Torres, Adolfo Antompietri and Jose Rivera

Flow-accelerated corrosion (FAC) can cause extensive damage to piping and equipment in fossil, nuclear and industrial power plants. This damage can lead to reduced plant reliability, unscheduled outages, loss of production, increased operating costs, and premature catastrophic failure of capital equipment. Since there are often no warnings to signal that a failure is imminent, FAC can pose a serious safety threat to plant operating personnel.

Over the past 40 years or so, the FAC mechanism has been studied and reviewed extensively in the literature. The primary variables that influence FAC corrosion are:

- Fluid velocity

- pH

- Metallurgy

- Geometry

- Temperature

- Steam quality

- Oxygen concentration

While many of these variables are established by plant design and operating practices, FAC can be minimized by elevating pH into an acceptable range. In some plants, ammonia is used for this purpose. Ammonia has the benefit of being a low-cost neutralizing agent that does not elevate steam or condensate cation conductivity. However, neutralizing amines are also employed for pH control in power plant feedwater and steam/condensate systems. Recent work has shown that neutralizing amines, if selected and applied properly, can provide certain advantages and treatment benefits over ammonia.

Flow-accelerated corrosion can occur in combined-cycle heat recovery steam generator (HRSG) applications, as well as in nuclear steam generation systems, paper mill recovery boiler systems and in fossil-fired utility systems.

FAC occurs on carbon steel when the protective layer of magnetite (Fe3O4) is dissolved in a stream of flowing water or in wet steam. For this reason, FAC can be classified as either "single-phase" or as "two-phase". The removal of the magnetite exposes the base metal to corrosive attack and can result in rapid localized metal loss. Due to the high pressures in power plant system piping and the localized nature of FAC, failures are sudden and often catastrophic.

The rate of FAC is affected by several variables that include velocity, geometry, metallurgy, temperature, oxygen concentration and steam quality. Systems that operate with velocities above about 17-20 ft/sec (5-6 m/sec) can be susceptible to FAC damage. Single-phase flow-accelerated corrosion is favored at temperatures between about 265 to 300oF. Two-phase FAC attack is maximized between 300 and 400oF.

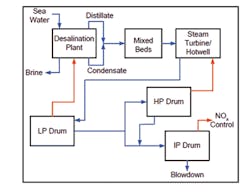

Simplified Schematic of EcoEléctrica HRSG Water and Steam Systems

Steam-generating equipment that operates below design pressure can increase the potential for FAC to occur. This is because the specific volume of steam/water mixtures increases as pressure is reduced, resulting in higher velocities throughout the equipment. The problem is aggravated further by operation of the equipment at steam loads that exceed the design capacity.

Given the temperatures, velocities and geometric requirements that favor FAC, it can easily be understood why FAC is more of a concern in the low-pressure (LP) and sometimes even in the intermediate-pressure (IP) sections of an HRSG. Similarly, economizers and shell-side feedwater heaters can also be susceptible to FAC attack.

Recent work has shown that low-pressure evaporators in HRSG plants can benefit from using properly selected neutralizing amines instead of ammonia for pH control and minimization of FAC. At normal treatment rates and with a properly selected neutralizing amine formulation, it is possible to achieve higher liquid phase pH than with ammonia alone. Furthermore, when ammonia feed rates are elevated to achieve a higher liquid phase pH, steam can become unusable for some applications.

The literature suggests that for all-ferrous systems operating under reducing conditions, a feedwater pH control range of 9.2-9.6 should be employed. In order to achieve the required pH with a neutralizing amine, the neutralizing amine must have the correct volatility and basicity characteristics so that the liquid phase pH will be elevated into the specified range.

Neutralizing Amine Chemistry

There are several different neutralizing amine components typically used in the treatment of boiler feedwater and/or condensate. Neutralizing amines each have different chemical properties, and it is important to understand the differences so that the correct components can be applied. Neutralizing amines typically applied in power plant systems are cyclohexylamine (CHA), methoxypropylamine (MPA), monoethanolamine (ETA), and morpholine.

Neutralizing amines are weak bases that are typically classified in terms of their "neutralizing capacity," "basicity," and "distribution ratio." The neutralizing capacity is a measure of how much amine it takes to neutralize a given amount of acid. Usually it is expressed as the ppm of CO2 (or carbonic acid) neutralized per ppm of neutralizing amine. Once the acid has been neutralized, each amine has a different ability to boost pH, which is accomplished by the hydrolysis of the amine to form hydroxyl (OH-) ions.

Distribution ratio refers to the volatility of the amine, which is one factor that helps determine how each amine component will partition between the liquid and steam phases. The distribution ratio of a particular amine also influences how much amine is recycled throughout the system, and how much amine will be lost from the system via boiler blowdown and steam venting.

While neutralizing amine chemistry may appear to be relatively straightforward, it is in fact quite complex. For example, the distribution ratio for a given amine is actually a function of pressure, temperature and pH. This means if you feed more or less neutralizing amine in a given system and affect the pH, the distribution of the amine between the liquid and steam phases will change as well.

In addition, the chemistry of neutralization is actually based on equilibrium chemistry of weak acids and weak bases. In many cases, there are multiple neutralizing amine components and acid components present so it becomes even more difficult to predict the amine distribution and pH profile across the system without using sophisticated computerized modeling techniques or without performing extensive empirical in-plant analyses.

The thermal stability of the neutralizing amine must also be considered when designing a treatment program to control FAC. Most amines degrade to some degree in an aqueous, alkaline, high temperature environment to form carbon dioxide, organic acids and ammonia. Morpholine, CHA, ETA, and MPA are considered the most thermally stable amines and are routinely employed in high-pressure power plant applications.

Case Study

EcoEléctrica owns and operates a 540 megawatt electric energy plant fired by natural gas, a liquefied natural gas terminal with one of the largest LNG tanks in the world, and a seawater desalination plant. The plant is located on the southwest coast of Puerto Rico in Punta Guayanilla in the municipality of Peñuelas.

EcoEléctrica commenced operation on March 21, 2000, and was the first independent power producer in the world to integrate a power generating plant with an LNG terminal. Under a 22 year power purchase agreement with the Puerto Rico Electric Power Authority (PREPA), the plant sells its capacity and associated energy to PREPA and produces about 13% of the island's electric power.

The plant operates two Siemens-Westinghouse 501F 184 mW combustion turbines that are fired with natural gas. Exhaust gases from the combustion turbine are used to generate steam in two parallel heat recovery steam generator (HRSG) units. The majority of the steam is used to drive one 214 mW Toshiba steam turbine/generator. Remaining steam is used in the thermal seawater desalination plant, and for NOx emissions control.

Since beginning operations, plant staff have used neutralizing amines to control pH and minimize flow-accelerated corrosion at the facility. The initial chemical treatment program, in use from March 2000 through January 2003, used a blend of sodium phosphates, hydroquinone for oxygen scavenging and passivation, and cyclohexylamine (CHA) for feedwater and steam pH control.

However, inspections of the two HRSG units in late 2002 and in early 2003 revealed that flow-accelerated corrosion had resulted in severe thinning of vortex eliminators in the LP steam drums and also in several steam separators. It was decided at this point that a change in treatment approach was needed.

Beginning in early 2003, a change was made in the neutralizing amine program. This change used a single-component formulation of methoxypropylamine (MPA) being injected at the condensate pump discharge. A 1:1 neutralizing amine blend of CHA and morpholine was also injected at a very low rate into the high-pressure boiler feedwater.

During this same period there were essentially no changes to the HP or IP boiler water treatment programs, and the hydroquinone feed was continued for oxygen scavenging and passivation.

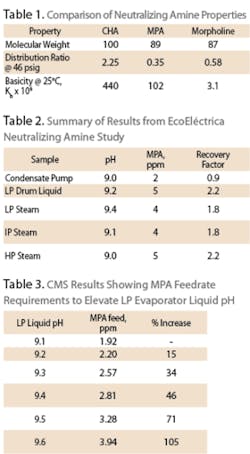

Table 1 shows some of the intrinsic properties of the three amines used at EcoEléctrica. As the table illustrates, MPA has a basicity constant that is slightly lower than CHA, but much higher than morpholine. MPA also has a lower distribution ratio than CHA so it stays in the LP liquid phase and protects the components against FAC damage. The molecular weight is shown on the table to enable comparison of each amine's capability to neutralize acid. Since neutralizing capacity is inversely proportional to molecular weight, the table shows that morpholine and MPA are better at neutralizing acidic components such as carbonic acid or organic acids than CHA.

Over the period of 2003 to 2007, inspections of the LP Evaporator showed no further evidence of FAC. Vortex eliminators and steam separation equipment showed no thinning or damage. No failures of any equipment were experienced.

2008 to Present

After a plant turnaround in early 2008, plant staff once again reviewed their neutralizing amine program to insure good control of FAC.

Operating data analysis revealed that the LP Evaporator liquid had an average pH of about 9.1 while guidelines published in 2004 recommended a pH range of 9.2-9.6 for controlling FAC in feedwater when operating with a reducing chemical treatment program. The plant wanted to upgrade their program and decided to implement a new pH control range of 9.3-9.5 in the LP Evaporator liquid.

To assist in developing the treatment guidelines for the upgraded neutralizing amine program, a Condensate Modeling System (CMS) from GE Water and Process Technologies was used in combination with specific amine analysis. As a first step, steam and condensate samples were collected across the plant while the plant was operating at full load. Each sample was analyzed for pH and conductivity at the plant site and duplicate samples were sent away for specific neutralizing amine and organic acid analysis. Neutralizing amine feed rates and system flows were logged at this time.

Once the amine and acid analyses were completed, a set of "recovery factors" was calculated for each amine at each location in the plant. Recovery factors are simply the amount of amine found at a given point in the system divided by how much amine was being fed. For example, if the plant were feeding 1 ppm of MPA based on the flow from the condensate pump discharge, and if 2 ppm of MPA were found by analysis downstream of the sample point, the recovery factor for that sample point would be 2/1 = 2.0.

Calculating recovery factors for the neutralizing amines across the system allows various "what-if" models to be developed using the CMS. These models allow the user to calculate the effects of changing amines and/or feed rates and to determine impacts on conductivity and pH across the entire feedwater, condensate and steam system.

Table 2 summarizes the data collected from both the field-testing and the specific amine analyses. At the time of the sampling, the feed rate of MPA was about 2.2 ppm based on the total flow from the condensate pump discharge.

The data from Table 2 was used to develop a CMS model of the plant. This information was then used to calculate the expected MPA feed rates required to boost the LP Evaporator liquid pH from its current average of 9.1 into the new range. The model demonstrated that a 34% increase in federate was required to elevate the pH of the LP Evaporator to 9.3 pH.

In fact, recent plant experience at EcoEléctrica shows that under certain plant conditions (i.e. low loads), it is very difficult if not impossible to keep the LP Evaporator liquid pH above 9.2. This is because under low load conditions, the amount of MPA recycled to the feedwater via turbine condensate is lower, so that additional amine feed is required.

CMS modeling and the analytical results revealed several other interesting facts regarding the amine treatment at EcoEléctrica:

- Significant losses of amine occurred at the deaerating condenser vent, mixed beds, IP drum blowdown, and IP steam that is used for NOx control and not returned to the boiler feedwater system. The majority of losses appeared to occur at the condenser vent.

- There was no impact on IP or HP boiler water pH due to the increased feed of MPA.

- The study showed that the supplemental feed of the 1:1 CHA/morpholine amine formulation to the HP feedwater was insignificant and unnecessary. Based on this finding, the plant has discontinued the feed of this chemical.

- Calculations showing the increased amine loading on the mixed beds by increasing the MPA feed was insignificant and would cause no reduction in throughput or water purity. This is because at EcoEléctrica the mixed beds are used only to purify the desalination plant distillate (containing no MPA) along with a relatively small amount of LP steam condensate that is used for heating in the desalination plant. These are not full-flow condensate polishers.

- The model predicted a small increase in the conductivity of LP steam with additional MPA feed. However, once the new program was implemented, it was decided to relax the previous conductivity limits on LP steam. These limits were being used to insure that seawater/brine leaks could be detected and that there would be no impact on mixed bed operation. Since it was understood that the small amount of extra conductivity was contributed by extra MPA in the system, and since the conductivity was monitored via trending only, it was felt that leaks could still be identified without putting the system at additional risk.

Conclusions

Organic neutralizing amine chemicals continue to have their place in the treatment of high-pressure power plant systems. These chemicals, when selected and applied properly can provide protection against damage from FAC.

In the example studied in this paper, an FAC problem was solved by properly applying a single component neutralizing amine formulation consisting of MPA. However, it is not suggested here that MPA is the solution for all power plant systems. The techniques applied here should be used to properly select and apply the right treatment. In some cases, different neutralizing amines may be needed, and in other cases a blend of different amine components may work best.

Acknowledgements

The authors would like to thank Carlos Reyes, EcoEléctrica Plant Manager, for his support of this project. Without his support and cooperation, it would not have been possible to produce this paper. The authors would also like to thank José Velázquez of EcoEléctrica who provided valuable assistance in collecting samples and providing system data for the study.

About the Authors: Robin Kluck has held numerous positions at GE Water and Process Technologies over the past 24 years, and is currently a Senior Technical Advisor in the Boiler Water Services group. Juan Torres has over 30 years of industrial water treatment experience and is currently an Account Manager at GE Water and Process Technologies. Adolfo Antompietri serves as the Operations Manager for EcoEléctrica and has been in his current role for almost six years. José Rivera is a Water Treatment Supervisor at EcoEléctrica where he is responsible for the safe and reliable operation of the water treatment systems. He has been in his current role for three years and with EcoEléctrica for 11 years.

Editor's note: This article was based on a paper presented at the 71st Annual International Water Conference, sponsored by the Engineers Society of Western Pennsylvania, San Antonio, TX, October, 2010.