By Ed Orvidas

Grey water reclamation depends greatly on having a thorough understanding of a plant's water balance, so that certain waste streams can be isolated, evaluated and then reclaimed. Within a typical plant, there are many opportunities to easily reclaim grey rinse water using ultrafiltration methods to remove dirt or suspended particles. The grey rinse water discussed throughout this article refers to "clean" dirty water - water that may contain some suspended particles but is not biologically or organically contaminated.

Once this grey rinse water has been ultra-filtered it can then be further purified using conventional RO treatment methods to enhance the purity of final reclaimed water; which can then be collected and redirected for possible reuse. However, it's important to keep in mind that for some processes that require extremely high quality water, it may not make economic sense to use reclaimed or recycled water. For that reason, it is essential to perform a water balance assessment, which can gauge if reuse of specific water streams will have an effect on your plant's overall wastewater discharge profile and your bottom line.

Water Balance

Successful and cost-effective grey water reuse in an industrial plant environment hinges on an understanding of a plant's water balance. With this understanding, it's possible to identify the best opportunities for water recycling and reuse. But how do you get there? The answer is a thorough water balance assessment.

Conducting an accurate water balance assessment, which looks at all of the different water streams that are created through a plant's various processes, can calculate the amount of water that is available for recycling and reuse. For example, in many beverage plants water that runs through purification equipment passes through a carbon filter. This filter must be backwashed and, at times, steam sanitized. A water balance assessment would show that a portion of the carbon fast rinse backwash water can be captured, pressurized and reused easily because it is very high quality.

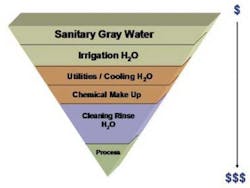

Additionally, this assessment can determine the water quality needed for a specific recycled water application and whether it makes economic sense to use recycled water. For example, the water quality needed for irrigation is of a lesser quality and therefore will cost less to purify and reclaim, while water that is reclaimed and destined to be used as clean-in-place (CIP) water needs to be of a higher quality and will cost more to reclaim.

The grey water/recycle water opportunities pyramid illustrates the cost, quality balance for specific processes using reclaimed water. For example, the water quality needed for irrigation is of a lesser quality and therefore costs less to purify and reclaim. However, the water that is reclaimed and destined to be used as CIP water needs to be of a higher quality and therefore will cost significantly more to reclaim.

During the assessment, it's also important to check with appropriate state and local health departments and other authorities to determine the water quality requirements for certain water uses, like irrigation or sanitary water. Working with these authorities can also help uncover piping requirements, which are used to prevent cross-contamination with a plant's potable water.

Likewise, when reusing water that touches production equipment it may also be necessary to confirm the required water quality and get approval from your company's corporate Quality Control department. This department may also need to validate the grey water reuse process and put any necessary quality checks and balances in place.

Quantifiable Sustainability

Flavor changes and CIP processes in beverage plants are an excellent example of the "green" benefits of grey water reuse. A typical beverage plant can conduct 10 to 30 CIP processes per day, requiring equipment to be sanitized and flushed after each flavor change. In certain circumstances, reprogramming of the CIP rinse process is not practical.

In these situations, and with an understanding of the water quality and the amount of water that is used during each CIP process, it's possible to determine how much water can be reclaimed during each flavor change and then reused in other processes. In some cases, a plant can capture the last 10 minutes of those 30 CIP processes - saving 15,000 gallons of water.

In Conclusion

Grey water reclaim is often seen as the ultimate "green" plant opportunity when it comes to water reuse and conservation. However, successfully water reclamation depends on a thorough understanding of a plant's overall water balance, water quality and individual water streams. With this understanding in place, companies can make educated and cost-effective decisions - while reducing their overall water usage.

About the Author: Edward Orvidas is a Strategic Account Manager at Culligan International. Previously, he spent seven years in field sales with Betz in the industrial water treatment chemical market. Has also has 18 years of water equipment purification experience in a variety of roles with Arrowhead Industrial Water, U.S. Filter and Siemens. Mr. Orvidas can be reached at [email protected].

Past IWW Issues