By Bob Kimball and Ken Klinko

Natural gas -- especially when it is produced from unconventional resources, such as coal seams, tight sands and shale formations -- is one of the fastest-growing energy sources in the United States and across the world. A primary consideration in developing this resource is the management of water produced in association with the gas. While the volume and quality of gas field-produced water vary considerably between basins, a common characteristic of almost all produced water sources is the presence of total dissolved salts (TDS) at concentrations that are typically well above the secondary drinking water standard of 500 milligrams per liter (mg/L).

Pilot-scale setup

Disposing of produced water requires a range of management and treatment approaches and depends on several site-specific factors, including water quality, flow, landowner lease agreements, economics, discharge options and a variety of other influences. Industry currently uses several different water management tools, such as direct discharge, managed irrigation, storage and infiltration, and deep well injection. In some cases, these options are not sufficient and the only feasible option is direct "end-of-pipe" treatment.

As development of the resources in the oil and gas industry increases, so too does the regulatory and public pressure to apply direct treatment in the field. Unfortunately, all end-of-pipe technologies currently in use in the oil and gas industry are limited by an array of technical challenges and a substantially higher cost in comparison to traditional, non-treatment alternatives. For TDS removal technologies, much of the cost is attributed to brine disposal. In fact, in some instances it has been shown that brine disposal accounts for nearly 50% of the cost of produced water treatment systems. Therefore, reducing the volume of brine requiring disposal is a key objective of most produced water treatment systems.

To help address these issues, CDM developed and field tested an innovative, water treatment solution for the removal of dissolved salts that maximizes treated water recovery for discharge or beneficial reuse, while minimizing chemical consumption and the volume of waste requiring disposal. The technology was originally developed for the treatment of coal-bed methane sources in the Powder River Basin of Wyoming and Montana. However, by modifying the pretreatment system the technology has much broader application for treating produced waters in other operating basins in the U.S., Canada and globally.

Process Description

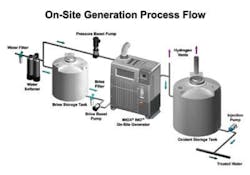

The patent-pending process developed by CDM uses combination of treatment technologies, including advanced filtration, ion exchange, reverse osmosis and evaporation, arranged in an optimized sequence that maximizes overall water recoveries with minimal chemical addition. This approach removes water quality limitations that cause membrane fouling so that the RO system is limited only by osmotic pressure. The treatment process consists of the following commercially available pre-treatment technologies in the following order:

- Filtration to remove suspended solids, including sub-micron particles (1 to 3 micron range)

- Efficient hardness and metals removal using a weak acid cation resin

- UV disinfection to minimize the potential for biological fouling

- High-recovery reverse osmosis at maximum operating pressure (currently limited to 1200 psig)

- On-site evaporation of the RO brine concentrate, if necessary

This pretreatment approach effectively removes all constituents that can cause membrane fouling. The only remaining constituent that prevents operating the RO system at the maximum recovery is silica. Until recently, silica management options were limited to the following:

- High pH precipitation with magnesium at elevated pH. This is costly due to the high reagent demand and volume of sludge produced.

- Ion Exchange using anion resin. While this is possible, it is cost prohibitive for produced water applications.

- Increase pH above 10.5 where silica is more soluble. This requires significant and costly chemical additions to raise the pH, especially for highly buffered water containing bicarbonate.

Another alternative, which is the basis of CDM's patent-pending approach, is to keep silica in solution in a supersaturated, or meta-stable state, long enough for the water to leave the RO system.

Full-scale facility under construction

The high-recovery RO treatment process includes the necessary pretreatment steps to allow super-saturation of silica without the removal of alkalinity or the continuous addition of chemicals for pH adjustment.

Pilot-Scale Testing

To demonstrate the efficacy of the treatment process, CDM conducted a full-scale continuous flow pilot test. The primary objectives of the pilot test were to verify the necessary treatment steps to maximize overall water recovery, evaluate membrane fouling potential, and develop the necessary information for full-scale design.

The he pilot-scale treatment system operated using feed water supplied from an operator's pipeline. The continuous feed rate to the treatment system was 3,500 barrels of water per day (BWPD) or 100 gpm. The final brine concentrate flow ranged from 65 to 100 BWPD (2-3 gpm).

Treatment steps consisted of:

- Storing feed water in a 5,000-gallon tank.

- Filtering the feed water through a cartridge filter. Various sized filters were tested.

- Removing polyvalent cations in a weak acid cation ion exchange softener.

- Disinfecting the water using a UV light.

- Treating the pretreated water in a multiple-stage RO system containing a combination of brackish and seawater membranes.

- Final concentrate was collected in a tank and re-injected back into the produced water pipeline.

Following are the major conclusions from the pilot test:

- The pilot successfully treated more than 500,000 gallons of feed at 98% recovery on an intermittent basis and more than 3.5 million gallons of water at an average recovery of 97%.

- Under steady state conditions, membrane fouling was found to be minimal.

- The product quality had a TDS of less than 500 mg/L, which will easily meet effluent limits for National Pollutant Discharge Elimination System discharge.

- Filtration was found to be a key pretreatment step, due to the very small particles present in the feed water.

- The weak acid cation ion exchanger performed better than expected, with one vessel treating more than 4 million gallons with no change-out or regeneration and a hardness leakage below the target value of 5.0 mg/L as CaCO3.

- Silica in the final brine concentrate was supersaturated, ranging from 200 to 280 mg/L.

Summary

In summary, the CDM high-recovery RO treatment process is a field tested and proven treatment system that is adaptable and cost-effective for the treatment of a wide range of gas field-produced waters. The RO process requires very little chemical addition and produces a minimal brine stream requiring off-site disposal. A full-scale system has been designed and is being constructed for treatment of 35,000 BWPD (1,000 gpm) of coal-bed methane produced water in the Powder River Basin. Startup is expected in spring 2011.

About the Authors: Bob Kimball, P.E., is a chemical engineer with nearly 22 years of industrial experience, having more than 13 years in the development, testing and design of full-scale produced water treatment systems in the oil/gas industry. He is an Associate in the Industrial Services Group of CDM, a global consulting, engineering, construction and operations firm offering a full range of services in water, environment, transportation, energy and facilities. Ken Klinko, P.E., has more than 38 years of industrial experience, including more than 28 years in water purification using reverse osmosis, ultrafiltration, and microfiltration membrane processes. He is a Vice President in CDM's Corporate Office of Project Development.

Past IWW Issues