Inland Empire Paper Company (IEP), located in Millwood, WA, specializes in the production of newsprint paper using a combination of mechanical pulp and recycled newspaper pulp. IEP produces an average 525 tons per day of newsprint and specialty paper products in 20 to 40 pound weight paper. Waste wood chips collected from local sawmills are processed to produce up to 475 tons of thermo-mechanical pulp (TMP) per day. IEP also recycles newspapers collected from around the country for the production of up to 350 tons of recycled newspaper fiber per day.

The bioreactor and related aeration system were installed in an existing stock tank. The tank was constructed of chemical and abrasion resistant tile-lined concrete furnished with a heeled bottom.

The recycled newspapers undergo a deinking process and are blended with the TMP prior to the bleaching process. IEP then dilutes the bleached pulp with water to lower its consistency to approximately 1% solids for introduction to the paper machine. Water is removed via a press and dryer process to produce paper with approximately 8% final moisture content.

IEP generates wastewater flows averaging 3.0 mgd, loaded with high strength BOD5. The wastewater is deficient in nitrogen and phosphorus, so ammonia and phosphorous are added to the system as essential nutrients for the activated sludge system.

Inland Empire Paper upgraded its wastewater treatment system to meet Washington State requirements for direct discharge to the Spokane River.

IEP also has a series of production campaigns for High Bright Paper runs that lead to higher organic loading and sludge bulking. The High Bright Paper campaigns run for a period of two days during which the wastewater treatment plant can see influent MLSS levels of over 5,000 mg/L.

Challenge

The challenge for IEP was to meet the stringent effluent discharge limitations set forth by the Washington State Department of Ecology for direct discharge to the Spokane River. This was achieved in part by retrofitting an existing Stock Tank with a Headworks Bio ActiveCell® Biological Moving Bed Biofilm Reactor (MBBR) capable of reducing the BOD5 load by 44% prior to reaching an existing Orbal oxidation ditch treatment system. The goals of the project were to off-load the oxidation ditch, minimize or eliminate the growth of filamentous bacteria and provide IEP with the capability for future growth in newsprint paper production. IEP also was planning for modular expansion in treatment capacity to meet more stringent effluent discharge limits and mill production increases in the future.

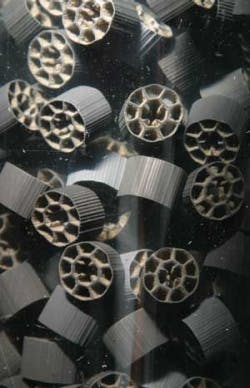

The 117,000-gallon bioreactor is loaded with a 67% fill fraction of ActiveCell450 biofilm carriers

Design

Inland Empire Paper treated wastewater from its paper making process with an existing wastewater treatment system consisting of three major components: 462,000 gallon primary clarifier, 3-channel 2.1 million gallon Orbal ditch aeration basin, and a 705,000 gallon secondary clarifier.

IEP conducted a four month pilot study using Headworks Bio ActiveCell450™ biofilm carriers that demonstrated the overall performance of the system along with the BOD5 loading and removal rates. The biological wastewater treatment system was designed using a combination of actual data from the pilot study and the MediaPro™ computer modeling program.

The ActiveCell bioreactor was sized and designed to remove BOD5 at a nominal rate of 7.15 kg BOD5 per cubic meter of carriers per day, approximately a 44% reduction of influent BOD5 load. The bioreactor was sized to fit within an existing 25 foot diameter x 38.5 foot high stock tank. The tank provides approximately 120,000 gallons of working capacity by operating at a nominal side wall depth of 34.5 feet (approximately 4 feet of freeboard).

The stock tank was constructed of chemical and abrasion resistant tile-lined concrete furnished with a heeled bottom. This tank happened to be one of the oldest tanks at the mill site, having been constructed in 1911.

Clarified wastewater from the IEP pre-clarifier is proportionally diverted to the bioreactor at a nominal flow rate of 1.58 to 2.05 mgd by means of a transfer pump and a set of control valves. Nutrients (ammonia and phosphorus) are then proportionally injected into the wastewater stream to support the biological activity of the treatment process.

The wastewater is prescreened by a self-cleaning screening device with a ¼" perforated screen and flows under pressure to the bioreactor, entering the bottom of the tank 180° from the suction point.

The 117,000-gallon bioreactor is loaded with a 67% fill fraction of ActiveCell450 biofilm carriers providing 400 square meters per cubic meter of active surface area. The neutrally buoyant biofilm carriers fluidized within the bioreactor provide a stable base for the growth of a diverse community of microorganisms. The biofilm is self-regulated by a continuous sloughing process due to the thousands of collisions per second. Excess solids exit the bioreactors via a wedge wire retaining screen as TSS with the treated effluent. This continuous sloughing action exposes the biofilm to the organic load in the wastewater and provides a self-regulated high-rate biological treatment process that is responsive to load fluctuations.

The neutrally buoyant biofilm carriers fluidized within the bioreactor provide a stable base for the growth of a diverse community of microorganisms.

The bioreactor is provided with process air from an IEP-supplied positive displacement blower. The air is diffused within the bioreactor by a 304SS coarse bubble aeration diffuser grid supplied by Headworks Bio.

The treated wastewater is pumped from the bioreactor via an internal retention screen riser mounted vertically to minimize air entrainment and to allow maximum wastewater retention within the bioreactor. The treated effluent is directed to the aeration ditch via a transfer pump controlled with a continuous level sensing device to maintain the target liquid level in the tank.

"The installation of Headworks Bio's Moving Bed Biofilm Reactor has virtually eliminated concerns of wastewater treatment system overload and sludge bulking," said Doug Krapas of Inland Empire Paper Company. "The MBBR now allows us to operate over a wide range of process changes and endure upset conditions. The Headworks Bio group worked closely with IEP personnel through all phases of the project to assure that we had a properly functional and efficient system operation."

The bioreactor process was commissioned in April 2007. Within three to four weeks of system start-up the system was already reaching the effluent quality targets. The system performance has met the design criteria for the reduction in BOD5 mass, and filamentous bacteria growth in the Orbal ditch has been greatly reduced throughout all operating seasons, aided by the reduction of organic acids in the bioreactor process. Clarifier SVIs have been reduced from ~990 down to the 300s.

Past IWW Issues