A227 MW gas-fired power plant operating in the southern United States generates electricity and steam for the public power grid and the adjacent oil refinery. To treat their make-up demin water, the power plant depends on six parallel reverse osmosis (RO) trains. In August 2009, the plant sought to upgrade performance of their RO system by replacing the membranes installed in two of the six trains. Important factors in membrane selection included better product quality, particularly in the removal of silica, consistent product flow and robust cleanability to recover product flow in case of a periodic upset in pre-treatment.

Each of the six reverse osmosis trains at the power plant contains 105 8” RO elements arranged in a single-pass, two-stage configuration. Each train is expected to produce 400 gpm of pure water using 571.4 gpm of feed (70% recovery). Pre-treatment before the RO includes sand filtration and cartridge filtration. Polishing after the RO is performed with a large mixed bed of ion exchange resin.

Leading up to the August 2009 decision to upgrade the membranes in two of the RO trains, all six trains had been operating with non-Dow membranes. The power plant decided to replace one train with Dow’s newly released Filmtec™ BW30HR-440i membrane, and to replace a different train with its predecessor, the Filmtec BW30-440i membrane.

Both of these Filmtec products benefit from an element construction that includes 440 ft2 of active area -- the most available in the industry today. They also both feature Dow’s patented iLEC™ Interlocking Endcap technology, which minimizes leakage around the o-ring that connects adjacent elements because the o-ring is seated firmly in a compression seal where it is not susceptible to the usual wear and tear experienced by standard interconnector designs.

However, the new BW30HR-440i, “HR” for High Rejection, additionally offers advantages from innovations in membrane chemistry. Higher rejection and higher flow typically oppose each other and an improvement in one usually comes with a compromise in the other. But with the latest chemistry developments from Dow, both were improved simultaneously in the BW30HR membrane. Additionally, the new HR membrane chemistry possesses fouling-resistant properties, which provides more consistent product flow and more reliable operation.

Installing new membranes in both trains at approximately the same time provided an excellent opportunity for the plant to test the benefits of the newer high rejection membrane against its predecessor.

Flow Rate and Energy Usage

A reliable supply of make-up water is required for any power plant; therefore, consistently producing an adequate flow rate of pure water is critical. Doing so at lower pressure pays dividends through energy savings and also widens the operating window so that the feed pump’s maximum pressure is still sufficient, even during cooler winter months.

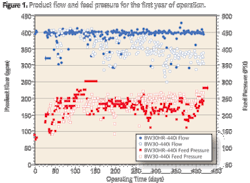

The RO train containing BW30HR-440i has very consistently produced 400 gpm of product water; the required feed pressure for this train increased from about 140 psi to nearly 300 psi as the feed water temperature dropped in the winter months, but then hovered around 225 ± 25 psi. Meanwhile, the train containing BW30-440i initially started producing 400 gpm of product water, but after about 150 days the product flow rate began to gradually decline to about 330 gpm despite attempts to compensate by increasing the pressure to about 250 ± 20 psi. Even though both trains have been periodically cleaned, typically about every three weeks as part of regular plant maintenance, the BW30HR-440i has demonstrated the ability to maintain 21% more product water flow with about 10% lower pressure.

Purity

High-pressure boilers in power plants demand high purity water. To achieve this stringent water quality, a polishing unit is used down-stream of the RO train. In this case, a mixed bed polisher is used. When the mixed bed polisher is exhausted, it must be chemically regenerated, which impacts operating cost.

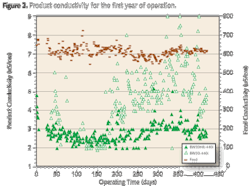

With few exceptions, the product conductivity from BW30HR¬440i is typically better than 3 µS/cm while the conductivity from the BW30-440i is typically above 3 µS/cm and trending toward a range of 4-7 µS/cm. Therefore, the ionic load reaching the mixed bed polisher is at least 25% lower (and sometimes better than 50% lower) with the BW30HR-440i, reducing chemical costs proportionately.

Any silica that enters the steam-condensate cycle through the make-up water becomes concentrated in the high-pressure boiler, and the fraction that partitions into the steam deposits on the turbines and reduces the efficiency of the generators. To prevent losses due to poorer turbine efficiency or higher blowdown rates, the mixed bed polishers are regenerated based on silica breakthrough. Regeneration frequency can be reduced, leading to cost savings in chemical consumption, when the upstream RO membranes reject more silica.

The concentration of silica in the product water is commonly half as much for the BW30HR-440i as it is for BW30-440i, helping to reduce the cost of regeneration chemicals spent on the mixed bed polishers.

Conclusion

After one year of operation at the southern United States power plant, the BW30HR-440i membrane produces more water using less energy than its predecessor. This saves operating cost through energy savings and provides peace-of-mind by extending the operating window so that a sufficient supply of make-up water can still be produced even in the colder seasons of the year.

At the same time, BW30HR-440i also produces higher-quality water that reduces the demand on the mixed bed polisher, saving money on regeneration chemicals for the mixed bed.

Plus, the superior rejection of silica made possible by the BW30HR-440i membrane reduces the amount of silica that must be removed by the mixed bed polisher, extending the throughput between regenerations of the polishing beds, and saving chemical costs.