By Tim Pickett and James Harwood

Selenium concentrations in industrial water discharges are targeted for reduction by regulatory agencies throughout the United States and Canada. As regulatory limits are being debated and evaluated at national and state levels, power utilities and mine sites are being forced to respond to regulatory requests. In addressing these looming regulations, mine sites and coal fired power-plants are challenged with reducing total effluent selenium concentrations while ensuring operator requirements and costs are kept to a minimum, so that the operation can maintain focus and profitability on their core business.

Removal of selenium to concentrations of less than 5 parts per billion (ppb) has proven to be a formidable challenge for conventional water treatment approaches. Biological treatment has emerged as the most effective means of removing selenium from various sources, including mine runoff, agricultural drainage and flue gas desulfurization wastewaters from coal-fired power plants.

One proven example of biological selenium treatment are fixed-film, packed-bed bioreactors—a process pioneered by GE with its ABMet technology. ABMet is a biological filtration system that relies on naturally occurring, non-pathogenic bacteria to precipitate selenium, thereby removing the constituent from the water stream. Within the biological filtration system, selenium is sequestered in a low-volume sludge that may be collected for disposal. The self-perpetuating microbial biocatalysts require only a nominal nutrient supplement and power supply, thereby resulting in very low operating and maintenance costs. In addition to selenium and nitrate removal, other constituents and trace metals can be co-precipitated, further increasing the overall benefit and value of the system.

Biological Selenium Reduction

Following equilibration, water can be conveyed to a bioreactor system for complete nitrate removal and total selenium removal to below 5 ppb in a single step. The ABMet bioreactors are filled with a permanent, porous substrate such as granular activated carbon (GAC), and are seeded with a naturally occurring, beneficial consortia of bacteria.

The bacterial strains used for seeding have been isolated from previously contaminated sites and chosen specifically for use in ABMet systems because of their hardiness in the extreme water chemistry as well as for their proven efficiency for selenium respiration and reduction. The bacteria form a fixed biofilm throughout the GAC substrate material, forming a cooperative microbial community.

In addition to increasing the efficiency of selenium removal, this communal structure also serves as a shelter, protecting the bacteria from chemical and physical upsets. These bacteria are facultative anaerobes, which flourish in oxygenated environments; however, when oxygen is depleted the bacteria use other compounds for respiration, resulting in the dissimilatory reduction of other oxianions present in the water. See Table 1.

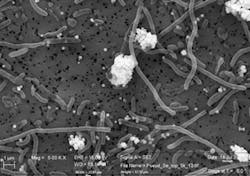

Aqueous selenium can be found in the form of oxidized selenate (SeO42-) but often contains some portion of selenite (SeO32-) and other soluble selenium species. With biological reduction, oxidized selenium is precipitated as submicron elemental selenium nanospheres. Therefore, for anyone evaluating selenium treatment technologies, it is important to choose a system that retains these particles; performance must be measured by total selenium values, not just the dissolved fraction that may not account for the fine colloidal selenium nanospheres.

A reducing environment is required to facilitate selenium reduction. The plug-flow design of the system allows gradational zones of decreasing ORP to form in layers throughout the biomatrix. As the ORP approaches 0 mV, denitrification occurs with the nitrate being reduced to nitrogen gas and released to the atmosphere. Complete nitrate reduction is achieved in the system.

NO3 + organic C → NO2 + organic C → N2 + CO2 + H2O

Deeper in the bioreactor bed, the ORP drops lower; dissolved selenate and/or selenite is reduced to an elemental state, precipitates out of solution and is filtered from the effluent by the biomatrix.

SeO4 + organic C → SeO3 + organic C → Se + CO2 + H2O

Reduction and precipitation of selenium occurs within a two-to-16 hour empty bed contact time (EBCT). EBCT is the residence time of the water, assuming there are no substrate, biofilm or solids present in the bioreactor.

Periodic degassing is required to release the gasses from the bioreactor bed. This is achieved with a small-volume, high flow of stored effluent water upwards through the bed, which releases the gases trapped within.

Collection of the precipitated constituents is achieved by a backwash cycle, which is strong and long enough to fluidize the biomatrix. This allows the release and collection of the contaminants and spent biomass. Attrition of the GAC has been insignificant at full-scale facilities to date and does not contribute to the minimal sludge volume.

A proprietary molasses-based nutrient is fed into the reactors as a carbon source for the bacteria (this carbon is a food source for the bacteria, and is not to be confused with the GAC substrate that serves as the permanent structure for the biofilm). The nutrient is fed into the influent line of the bioreactors, using a static mixer to ensure the system is evenly fed.

Bioreactor Engineering & Design

The bioreactors are designed for plug-flow, ensuring even distribution of the feed water and maximum contact with the bacteria throughout the filtration bed. The system uses parallel trains with each train consisting of a first-and second-stage bioreactor cell. The systems are scalable to virtually any flow size by the addition (or reduction) of trains and by varying the volume of the individual cells. Each of the bioreactors in the first- and second-stage is identical, which allows for alternate cycling and continuous operation during degas and backwash cycles.

Water is fed into the top of the bioreactors and flows evenly across the top of the beds through distribution piping. The water passes down through the bed and is collected via a manifold located in a gravel sub-fill in the bottom of the reactor. The effluent from the first-stage bioreactors is pumped into the top of the second-stage bioreactors.

Periodically, the denitrification occurring within the system will cause gases to build up and form pockets within the media. These pockets can have a negative effect on the process by allowing the water flow to channel, resulting in reduced microbial contact and increasing head-loss across the bioreactors. A degassing sequence is employed in which a backwash pump pushes water at a high flow rate into the bottom of the bioreactor via a dedicated manifold. The flush duration is long enough to expand the bed and allow the entrained gases to escape, but short enough to avoid wasting any water out of the bioreactor.

Head-loss through the bed is monitored using level transmitters and a baseline level point. If a degas does not recover the head-loss, an accumulation of solids in the bioreactors is likely and a backwash is required.

Solids in the form of captured total suspended solids (TSS) from the wastewater, precipitated selenium, metals and excess biomass will build up over time. A high-flow backwash (similar to the degas) fluidizes the active media, dislodging the trapped solids and carrying them out of the bioreactor as overflow. The media remains in the bioreactor, leaving the active bacteria population for continued operation. The resulting sludge is de-watered and disposed.

Modular System

GE recently launched a next-generation ABMet system that offers a 50-75% reduction in footprint with a modular, skid-mounted equipment package, designed for rapid deployment and ease of installation.

At the heart of the modular system is a packed-bed biofilter, which can be fed by a small pump skid or by gravity. The system is seeded with a naturally occurring proprietary blend of selenium reducing bacteria, which colonize the granular activated carbon filter media.

Packed beds do not need continuous expansion as in a fluid bed reactor. Therefore, there is no need for a large, continuously operating recycle pump, resulting in a substantial energy cost savings. Another feature of the packed bed is the retention of biomass and the sub-micron elemental selenium particles that form in the bed as result of biological selenium reduction. Selenium is removed in a single step, negating the need for additional post-filtration step to remove these sub-micron particles.

Conclusion

Bioreactor systems have emerged as the new “best practice” for selenium treatment and are setting the standard in mining, power generation, agricultural drainage, and other industries. These challenging waters require novel treatment approaches, and bioreactor technology continues to emerge to address the challenge. As evident by the myriad full scale treatment systems installed over the last decade, this approach can truly reduce total effluent selenium concentrations while ensuring operator requirements and costs are kept to a minimum, so that the operation can maintain focus and profitability on their core business.

About the Authors: Tim Pickett is a senior product manager for GE Power and Water and manages the ABMet product line. Picket was the developer of ABMet, which was acquired by General Electric as part of its Zenon acquisition in 2006. His experience includes applied microbiology, water treatment technology evaluation and validation, technical marketing, business development, management and technical sales. James Harwood is the North American industrial sales manager for GE Power and Water’s ABMet product line. In his role, he has responsibility for business development, marketing and implementing biological treatment solutions for the removal of selenium and other inorganic constituents in power, mining and other heavy industrial applications.