By Holly Hills and Matthew Heermann

The U.S. Environmental Protection Agency (EPA) regulates wastewater discharges from power plants through the 40 CFR Part 423 Steam Electric Power Generating Effluent Guidelines and Standards (ELGs). On June 7, 2013, EPA proposed amendments to the existing ELGs. The proposed changes would revise the wastewater treatment and discharge requirements for steam electric generating units (EGUs). The final rule is currently in interagency review and is expected to be published September 2015.1

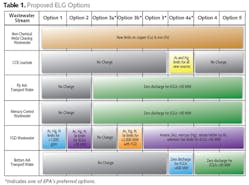

Although the proposed amendments would apply to all steam EGUs, the changes would primarily impact wastewater streams at coal-fired power plants. Several options identified in the proposed amendments would establish new requirements for wastewater from wet flue gas desulfurization (FGD) scrubbers; fly ash and bottom ash transport water; coal combustion residual (CCR) leachate; and non-chemical metal cleaning wastewater. Table 1 summarizes the proposed options as they apply to these streams.

Based on a review of typical streams generated by coal-fired EGUs, it is anticipated that the proposed ELGs would have large impacts on units that currently utilize water to transport their ash (i.e., wet sluice their fly ash or bottom ash) and units equipped with wet FGD scrubbers.

FGD Wastewater Proposed ELG Compliance

Potential options for complying with the proposed arsenic (As), mercury (Hg), nitrogen (N), and selenium (Se) limits for FGD wastewater include, but are not limited to: enhanced physical/chemical treatment, biological treatment, and thermal evaporative or zero liquid discharge (ZLD) systems. Coal-fired EGUs with newer wet FGD systems are more likely to include existing physical/chemical wastewater treatment (WWT). However, even if these WWT systems are designed to remove arsenic and mercury to levels consistent with the proposed standards, further treatment would be required to remove remaining nitrates/nitrites and selenium via biological treatment or ZLD for compliance with the proposed ELGs. Biological treatment systems tend to be high in capital cost and require significant footprint. The proposed ELG includes a five-year schedule incentive for compliance using a ZLD approach if the ZLD system eliminates all process wastewater discharges. Various types of ZLD solutions are commercially available, including but not limited to: brine crystallizers/evaporators, wastewater spray dry absorbers (SDA), and fixation/stabilization. The following is a summary of these technologies.

Brine Crystallizer/Evaporator

A brine crystallizer/evaporator utilizes steam to evaporate FGD wastewater, concentrating salts for dewatering and disposal. This process produces a high purity water stream that can be reused within the plant site. A ZLD brine crystallizer/evaporator requires high capital and operating and maintenance (O&M) costs, including significant power consumption requirements. In addition, the concentrated salts may require additional conditioning before disposal in a landfill because they are difficult to dewater.

Wastewater Spray Dryer

FGD wastewater can also be evaporated in a wastewater spray dryer where a slipstream of hot flue gas from the boiler outlet is diverted to the spray dryer and the residual heat is used to evaporate the water. If a plant has an existing physical/chemical WWT, it is possible that with this approach the use of physical/chemical treatment would no longer be required. Due to the arrangement of this option, the solid waste is collected in an existing particulate collection device installed on the boiler. There is limited experience using this technology and there are some risks that the concentrated salts could impact the downstream particulate collection equipment.

Waste Fixation and Stabilization

An alternate method for eliminating FGD wastewater is use in waste fixation and stabilization. Wet FGD byproduct (or gypsum) can be structurally stabilized and chemically fixated by mixing a proportioned blend of water (FGD wastewater), gypsum, ash and lime for disposal in a landfill. The resulting fixated waste is physically stable, making it easier to handle. The mechanism to achieve this stability is the reaction of silicates in the ash with lime to form a cement-like product, which gradually strengthens over time. Fixation/stabilization is useful for landfill disposal as the material resists reliquification and channeling, and minimizes leaching.

ZLD System Sizing

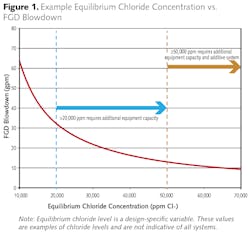

An important variable influencing the cost of ZLD technology is the flow rate processed by the ZLD system. Although a newly installed ZLD system could be designed to treat all process wastewater, one method to reduce FGD wastewater would be to change the absorber materials to allow for higher chloride concentrations, thereby reducing the need to purge chlorides from the system. The quantity of FGD wastewater decreases as the equilibrium chloride in the scrubber increases. The following graph shows an example correlation for a 500 MW unit burning a bituminous, high sulfur coal (see Fig. 1).

Because increased chloride concentrations in the FGD have the potential to impact the ability of the system to capture SO2, as chloride concentration increases, modifications to the existing equipment may be required, such as increased equipment capacity (>20,000 ppm) and an additional additive system (>50,000 ppm). For these ZLD approaches, in addition to the cost of changing the absorber lining material, the cost of equipment capacity and an additive system may be incurred in order to accommodate reductions in the quantity of FGD wastewater associated with the respective increased chloride concentrations.

Economic Analysis

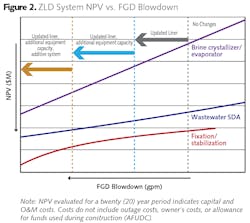

The net present value (NPV) cost of the three ZLD options were evaluated at various amounts of FGD wastewater and are shown in Figure 2. The cost of the FGD modifications would be equivalent for each technology.

As shown, a fixation/stabilization system could be the lowest cost for ZLD compliance with the proposed ELGs. However, a fixation/stabilization system may not be able to completely eliminate all wastewater based on achieving the required solids concentration. Therefore, a fixation/stabilization system will generally be more economical for smaller quantities of wastewater. Design considerations that should be made for a brine crystallizer/evaporator include the high capital and power consumption, as well as the additional disposal costs. A wastewater spray dryer design would tend to have a higher capital cost compared to fixation/stabilization, and may impact downstream particulate collection equipment and fly ash sales.

Summary

A ZLD approach for FGD wastewater treatment has many benefits when considering compliance with the proposed ELG. There is a five-year incentive and in addition, ZLD systems could eliminate all process wastewater discharges, not just FGD, allowing compliance with all wastewater stream requirements established by the ELGs. Reducing the amount of wastewater to be treated will reduce the overall cost of a ZLD system, which may allow ZLD approaches to be more widely considered for ELG compliance. All compliance approaches are plant-specific and a water reduction/reuse study to minimize costs is usually beneficial when considering potential approaches for compliance with the proposed ELGs.

About the Authors: Holly Hills is an environmental engineering associate for Sargent & Lundy’s Environmental Services Group, supporting utilities in developing and implementing compliance strategies for current and impending regulations associated with flue gas and water effluent emissions. She is a chemical engineer with 4 years of industry experience.

Matthew Heermann, PE, is a water and wastewater engineer for Sargent & Lundy. His prior work experience includes serving two years as a power plant water treatment engineer and chemistry technician in both the nuclear power and the radio-pharmaceutical industries.

Notes:

1. At the time this article was submitted, the EPA had not released the final modifications to the ELGs.