By Johanna Ludwig

Today, because of increasingly strict environmental regulations, escalating disposal fees and the complexities of wastewater discharge, refineries tend to seek out advanced technologies to decrease their water footprint. Modern polymeric membrane-based technologies, such as ultrafiltration (UF) or membrane bioreactor (MBR), are not always able to handle the high fouling caused by complex refinery wastewaters. In this article, the results, design and OPEX calculations of a successful four-month field pilot employing a flotation-filtration technology based on new ceramic membranes are presented. The technology, akvoFloat™, was placed at a German refinery for a complete wastewater reuse project (250 m³/h).

Background and Approach

The presented pilot system was set up to treat the effluent of the existing wastewater treatment plant, comprising biological treatment (activated sludge) and a sand filter. Currently, the effluent is discharged into a nearby river, but the user’s future intention is to find a solution to reuse the effluent as boiler feedwater.

The technology screening study identified the main contaminants: suspended solids and colloidal matter (turbidity), organic matter (TOC) and microbes (CFU). The organics were mainly breakdown products and high-molecular-weight humic substances. Some contaminants, such as free chlorine, nitrates, sulfates and some metals (strontium, barium, manganese, aluminum, and iron) must be treated chemically, although they were of minor interest in the executed field pilot test. The intention of the project was to design a treatment train that meets the demanding reverse osmosis (RO) feed quality requirements, since the operator chose RO for the desalination step.

An almost complete elimination of microbes and turbidity was indicated by a provisional laboratory test, as well as a considerable decrease of the organic load with the akvoFloat technology. Two polishing steps, granular activated carbon (GAC) and advanced oxidation processes (AOP), were considered for further reduction of the organic load. Due to costs and complexity, the operator chose GAC. A four-month pilot trial was set up in the refinery in order to gather information about long-term behavior, fouling and operational parameters, and to validate the laboratory test results.

The Core Technology

The separation technology, akvoFloat, is based on a proprietary flotation-filtration process. The feed water first enters the flotation zone, where the MicroBubble Generator™ induces fine gas bubbles (50-70 microns) using very little energy and equipment. Unlike dissolved air flotation (DAF), it does not require a saturator or a water recycle stream. The microbubbles attach to suspended matter, oils, hydrocarbons and organic flocs, which are carried to the surface.

The float layer that forms on the surface is skimmed off the tank at regular intervals. The partially treated water then enters the filtration zone where submerged flat sheet ceramic membranes (pore size down to 0.1 micron) are used as a polishing step. They provide high, constant permeate quality with very low pressure drop. akvoClean, a proprietary membrane cleaning process based on fast oxidation, provides reliable removal of fouling and cost-effective system operation.

Pilot System: Description and Operation

Figure 1 shows all parts of the pilot system (akvoFloat unit, GAC and RO unit), which were placed in a container. The effluent from the sand filter is fed by a submerged pump to the pilot container at a feed rate of about 2 m3/h. Ferric chloride sulfate is being used as a flocculant during the akvoFloat process. The most effective dosage for good flocculation was 10 ppm. Adding polymer to the flocculant did not improve the effectiveness.

The MicroBubble Generator worked at an air flow rate of about 60 L/h and an air pressure of approximately 1 bar. During the pilot phase, the flux of the ceramic membranes was varied up to 200 L/m2/h.

After the akvoFloat process, the effluent was supplied to a barrel with 200 L of macroporous activated carbon, since it proved to be the most effective method for removing high-molecular-weight organics. Furthermore, the technology screening study preliminary laboratory tests indicated that macroporous activated carbon had the highest TOC removal rate. The flow rate for the GAC guaranteed a minimum contact time of 10 minutes.

To prove the efficiency of the akvoFloat + GAC system, an RO skid consisting of a single membrane module was installed. The goal was to assess the biological fouling on the RO membranes, the main concern for the operator.

Better than Polymerics

In addition to the regular backwash process during normal operation, there are two types of chemical procedures that are necessary for all membrane-based technologies. Chemically enhanced backwash (CEB) and chemical cleaning in place (CIP) help to remove fouling and to recover the permeability of the membranes. These procedures have an impact on downtimes, required membrane area, chemical consumption and amount of wastewater.

The akvoClean cleaning method removes foulants by fast oxidation. This very aggressive cleaning method is made possible by the chemical and mechanical robustness of ceramic membranes. Compared to CEB and CIP, akvoClean uses 80 percent less chemicals and 99.5 percent less time, reducing downtimes and product water loss, and minimizing operating costs.

Results

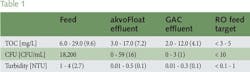

The key parameters for achieving steady and long-term operations are the TOC levels and the turbidity of the sand filter effluent, the akvoFloat effluent and the GAC effluent. The CFU, which is an indicator of the amount of microbes, was analyzed from the aforementioned streams every two weeks.

The removal of CFU and turbidity with akvoFloat is remarkably high (99.9 percent CFU removal and turbidity < 0.1 NTU can be reached) and sufficient in terms of RO pretreatment. As concluded in the technology screening study, additional polishing is needed in terms of TOC as the removal rate was slightly lower than expected based on the preliminary lab test results. In combination with the GAC filter the total TOC removal is about 60 percent.

Table 1 shows the minimum, maximum and average values of the key parameters and streams. Regarding TOC removal, the GAC filter operation was satisfactory. An acceptable value of 4.0 mg/L for TOC could be reached consistently. No fouling or scaling took place during the pilot phase, which could be determined through the consistent pressure of the RO element and a posterior membrane autopsy.

Membrane Fouling Control

The cleaning process demonstrated an effective removal of foulants. Daily, the fouling layer on the ceramic membranes was removed while maintaining continuous operation even during the worst water quality periods. A variation of the fouling behavior of the ceramic membranes occurred due to fluctuations in influent quality with regard to TOC composition, likely caused by upstream events putting stress on the biological treatment process. However, irreversible fouling problems never occurred, so the full recovery of the permeability of the membranes was always achieved with akvoClean.

Next Steps

In order to get a solid estimate of the capital and operating costs, akvola Technologies started with the design of a full-scale solution. The system will be integrated in three trains. The current OPEX estimations are 20 percent lower compared to the previously piloted polymeric MBR technology.

Conclusion

The suggested treatment chain with akvoFloat and GAC can reliably deliver RO feed water quality. The combination of the ceramic membranes, the microflotation pretreatment embedded in the akvoFloat process, as well as the akvoClean cleaning strategy provided a successful field trial. The trial data shows an improved alternative to the conservative polymer membranes previously employed at the plant.

About the Author: Johanna Ludwig, CTO at akvola Technologies, has over 10 years of experience in water treatment technology development, application and commercialization. At akvola Technologies, Ludwig has guided R&D activities since the company’s founding in 2011.