By William M. Copa, Bryan Kumfer and Thomas J. Vollstedt

A variety of organic compounds are classified as refractory when they're poorly biodegraded and/or exhibit a low value for the ratio of biological oxygen demand to chemical oxygen demand (BOD:COD).

Compounds such as t-butyl alcohol found in perfumes and cosmetics, and 5,5-dimethyl hydantoin, used in the manufacture of pharmaceuticals, exhibit low BOD:COD values and are considered poorly biodegradable. Compounds such as hexamethylenetetramine (HMTA), used in the manufacturing of explosives, and chloroform, a common chemical intermediate, have zero values for their BOD5 concentration and are therefore reported to be non-biodegradable.

The disposal of these chemicals or of waste streams containing these materials is often problematic. Using a wet air oxidation process developed in the late 1950s by USFilter's Zimpro Systems, of Rothschild, Wis., for pre-treating wastewaters considered refractory or inhibitory, however, has been shown to facilitate disposal by means of biological treatment.

Zimpro® wet air oxidation is used for treatment of industrial wastewaters and in-process applications. The process also has been used extensively for sludge treatment and destruction applications. More than 150 custom-designed wet oxidation systems are in use worldwide.

The Process

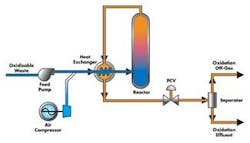

Wet oxidation is the oxidation of soluble or suspended components in an aqueous environment using oxygen as the oxidizing agent. When air is used as the source of oxygen, the process is referred to as wet air oxidation (WAO). Oxidation reactions occur at temperatures of 150-320°C (275-608°F), and at pressures from 10-220 bar (150-3200 psi). The required operating temperature is determined by the treatment objectives and the ease or difficulty in oxidizing the components. Higher operating temperatures require higher pressure to maintain a liquid phase in the system.

The typical WAO system is a continuous process using rotating equipment to pressurize the feed stream and air to the system operating pressure. Heat exchangers are routinely used to recover energy from the reactor effluent, which is then used to preheat the feed/air mixture entering the system. Auxiliary energy, usually steam, is necessary for startup and can provide heat if required.

The reactor vessel provides residence time at the desired operating temperature enabling propagation of the oxidation reactions. Since the oxidation reactions are exothermic, sufficient energy may be released and recovered to allow the WAO system to operate without any additional heat input.

Organics Destruction t-butyl alcohol

Bench-scale tests using wet air oxidation to treat a 10 g/L aqueous solution of t-butyl alcohol at 220, 240, and 260°C, using a 60 minute time at temperature were shown to achieve COD removal efficiencies of 56.3, 54.6, and 68.3%, respectively at 220, 240, and 260°C. Corresponding TOC removal efficiencies of 56.3, 51, and 62.4% were also reported. BOD values of the wet air oxidized effluents were drastically increased when compared to the BOD of the untreated t-butyl alcohol solution. The BOD/COD values of the oxidized effluents were 0.39, 0.49, and 0.79, for the oxidation tests at 220, 240, and 260°C, respectively.

A respirometry test on the oxidized effluent from the run at 260°C showed a high oxygen uptake, at a 20 fold dilution, equivalent to 64% of the COD. In comparison, the untreated t-butyl alcohol solution showed an oxygen uptake, at a 20 fold dilution, equivalent to only 1.2% of its COD.

Hexamethylenetetramine

Wet air oxidation tests were conducted on a 10 g/L aqueous solution of HMTA at 220, 240, and 260°C, using a 60 minute time at temperature. Treatment by wet air oxidation achieved a COD removal efficiency of 81.8, 83.1, and 86.5%, respectively at 220, 240, and 260°C. Corresponding TOC removal efficiencies of 65.9, 81.3, and 88.4% were also reported.

The BOD values of the wet air oxidized effluents were greatly increased when compared to the BOD of the untreated HMTA (hexamine) solution. The BOD/COD values of the oxidized effluents were 0.73, 0.65, and 0.59, for the oxidation tests at 220, 240, and 260°C, respectively. The respirometry test on the oxidized effluents showed a high degree of biological degradation when compared to the respirometry test on the untreated HMTA solution.

The respirometry test on the oxidized effluent from the run at 260°C showed a high oxygen uptake, at a four fold dilution, equivalent to 57% of the COD. In comparison, the untreated HMTA solution showed an oxygen uptake, at a 25 fold dilution, equivalent to only 4.7% of the COD.

Tests conducted on other refractory organics produced similar results – the difficult-to-treat compounds in each case were made amenable to biological treatment in all cases.

Testing Benefits

Bench scale and pilot testing are an excellent way to let customers "try before they buy." Either completed on-site or off-site, bench scale and pilot tests are put to use in real world situations to find the best and most cost-effective solutions for each application. Most often, the cost of the test work is saved many times over in full-scale plants that are more efficient and operate more trouble-free.

Bench scale autoclave testing is used to establish preliminary design criteria for a full scale design, allowing for evaluation of process economics. In addition, materials-of-construction testing can be conducted in autoclaves to identify suitable alloys for an application. Studies also can include other treatment processes, like biological treatment, that can be coupled with WAO for effluent polishing.

Continuous flow pilot studies can be performed under a wide range of operating conditions. Pilot plant studies are done to optimize the design conditions for custom applications, and produce representative treated product for evaluation and further testing. Pilot systems are constructed of various alloys, including titanium and high nickel alloys. The WAO system configurations are typically customized based on the specific process approach.

Conclusion

Wet air oxidation of refractory compounds can result in formation of oxidized effluents that are much more biodegradable than the starting compound. Therefore, effluents produced from wet air oxidation of aqueous solutions of these refractory compounds exhibit high values for BOD:COD ratios, and also show higher oxygen uptakes than their respective untreated parent compounds in respirometry tests, indicating they're more amenable to biological treatment.

About the Authors:

William M. Copa is research and development director for USFilter's Zimpro Systems, based in Rothschild, Wis. Copa joined USFilter in 1962. With a bachelor's degree in chemistry from South Dakota State University, and a doctorate in analytical chemistry from the University of Minnesota, he's a member of the American Chemical Society. Thomas J. Vollstedt is senior process development engineer for USFilter's Zimpro Systems. Vollstedt joined USFilter in 1970. He holds a bachelor's degree in chemical engineering from the University of Wisconsin and is a member of AIChE. Bryan Kumfer is an oxidation chemist for USFilter's Zimpro Systems. Kumfer joined USFilter in 2003, and has a bachelor's degree in chemistry from Northland College in Ashland, Wis. For more information, call 800-525-0658 800-826-1476 or visit www.zimpro.usfilter.com.