The worldwide wastewater minimization market has been driven by a few key issues: pollution prevention, water recycling, water reuse and zero liquid discharge. These drivers have been brought about by global water shortages, increasing population and more stringent environmental regulations - all of which increase the cost of clean water and lead to the need for more efficient use of water supplies.

In fact, new government-mandated corporate waste reduction goals and public disclosures of toxic chemical discharges - along with those four key issues driving the international wastewater minimization market - have encouraged U.S. companies to investigate and implement water reuse strategies. Commercial users here and globally are evaluating process improvements to enable them to conserve water and, in turn, decrease wastewater volumes. Furthermore, limited capacity of publicly owned treatment works (POTWs) and economic benefits of reusing water are increasing demand for complete water recycling systems across industrial, agricultural and residential segments. This includes tertiary treatment for irrigation water, as well as closed-loop systems whereby wastewater is recycled for cooling, makeup or process water needs. Deployment of water recycling systems has helped offset increases to water costs, proving a worthwhile investment for end-users by providing long-term savings.

EPA Rules Spur Growth

Wastewater discharge regulations have become increasingly more stringent, spurring a growth in water reuse and conservation. These regulations include limits on types and concentration of chemicals in discharged wastewater. U.S. Environmental Protection Agency (EPA) guidelines for water reuse and discharge limits on wastewater encourage end-users, particularly industrial facilities, to consider deployment of water recycling systems.

EPA regulates the discharge and treatment of wastewater under the Clean Water Act (CWA). The National Pollutant Discharge Elimination System (NPDES) - see http://cfpub.epa.gov/npdes/ - issues permits to all wastewater dischargers and treatment facilities. These permits establish specific discharge limits, monitoring and reporting requirements and may also require industrial, municipal and other facilities to undertake special measures to protect the environment from harmful pollutants.

Effluent guidelines (see www.epa.gov/OST/guide/) are national standards for wastewater discharges to surface waters and POTWs (municipal sewage treatment plants). EPA issues effluent guidelines for categories of existing sources and new sources under CWA Title III. The standards are technology-based (i.e., based on performance of treatment and control technologies); they aren’t based on risk or impacts upon receiving waters.

Other Influences

Other recent developments - global water shortages, wastewater treatment process improvements and increased environmental responsibility initiatives - also have increased industrial interest in wastewater minimization technologies.

Water Shortages: Over the years, clean/fresh water supplies available for municipal, commercial and industrial users have declined on a global level due to use of an already limited supply and drought conditions. As a result, it has become important to incorporate treatment technologies that minimize overall production of wastewater while producing reuse water that can then be injected back into the treatment process.

Process Improvements: In general, most wastewater minimization treatment processes (e.g., ultrafiltration, reverse osmosis, ion exchange) typically associated with high operating and capital costs have been reengineered to offer process improvements while reducing cost, making them more attractive treatment options.

Environmental Responsibility: Whether through regulatory or self-imposed measures to positively impact the environment, global “green” trends are prompting industrial producers of wastewater to seek treatment methods that limit their direct and negative impact on the environment.

In addition, zero liquid discharge (ZLD) is gaining popularity as a wastewater treatment method since it eliminates water discharge by recycling it into the process with solid waste extracted from wastewater during ZLD treatment the only disposal element of the process.

New Strategy for Coal

Coal is the most abundant energy source in the world, and it’s a major source of hydrocarbons, particularly gas. Large amounts of methane-rich gas are generated and contained in coal bed seams, but only recently has coal been recognized as representing an enormous undeveloped “unconventional” energy resource. In recent years, commercial production of coal bed methane (CBM) has been undertaken in the United States, and this development is expanding to other countries.

Production of CBM is accompanied by significant environmental challenges. Production requires pumping water to extract the gas. This produced water, separated from the gas in the borehole, contains high levels of sodium (Na) and carbonates (CO3). More stringent federal and state water regulations now prohibit the discharge of this water into the environment or its use for irrigation due to high salt content.

Chemical treatment of CBM-produced waters can be economically prohibitive, so the industry has long searched for safe, affordable treatment alternatives to meet regulatory standards.

Since 2003, the Higgins LoopTM continuous ion exchange technology has been shown to offer a proven, economical and efficient process for the purification of produced water without the generation of hazardous wastes or large byproduct streams.

Ion Exchange in CBM Process

In Wyoming’s Powder River Basin, efforts to access a major source of natural gas stalled when drilling for coal bed methane also produced millions of gallons of tainted groundwater. To release the methane gas, water trapped in the underground coal seams had to be pumped to the surface. The water was so laden with sodium that it couldn’t be used for irrigation or released into nearby streams.

Typically, the water would be stored in huge pits, reinjected into the ground or treated chemically. None of these solutions was satisfactory to the owner of the land’s surface rights where a gas exploration company was planning to drill. But a partnership between EMIT Water Discharge Technology, of Sheridan, WY, and Severn Trent Services, of Ft. Washington, PA, produced a solution that has produced positive results.

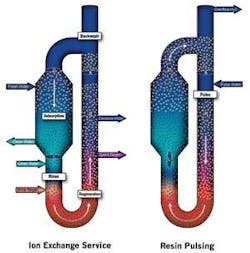

The Higgins Loop process incorporates a continuous countercurrent ion exchange contactor for liquid phase separations of ionic components using ion exchange (IX) resins. The Higgins Loop contactor is a vertical cylindrical loop, containing a packed bed of IX resin that is separated into four operating zones by butterfly, or “loop” valves. These operating zones - adsorption, regeneration, backwashing and pulsing - function like four separate vessels.

Produced water containing high Na levels is fed to the adsorption zone within the Higgins Loop where it contacts strong acid cation resin which loads Na ions in exchange for hydrogen (H) ions. Treated water exits the loop containing less than 10 mg/L Na. The carbonate contained in the water, also harmful to the environment, is removed via carbon dioxide (CO2) evolution from the low pH treated water. The Higgins Loop’s features are ideally suited for this application where only cation exchange is required to remove high levels of Na, CO3 and total dissolved solids (TDS).

Concurrent with adsorption and in the lower section of the Higgins Loop, Na-loaded resin is regenerated with either hydrochloric or sulfuric acid to produce a small, concentrated spent brine stream. Regenerated resin is rinsed with water prior to reentering the adsorption zone to remove acid from its pores.

As resin in the upper layer of the adsorption zone becomes loaded with Na, the flows to the Higgins Loop are momentarily interrupted to allow advancement of the resin bed (pulsing) through the loop in the opposite direction of liquid flow. Liquid flows are restarted after resin pulsing is complete.

Treated water is slightly acidic due to its increased H ion strength. This is neutralized with limestone, which also increases the water’s calcium concentration so that its sodium adsorption ratio (SAR) is less than 1.0. Spent brine containing removed Na ions has a density high enough for use as a kill fluid - a dense solution used to seal old wells.

The Higgins Loop technology makes water with high levels of Na and CO3 safe for reintroduction to the environment. The byproduct water, which once was an environmental problem, now is being reused by ranchers for irrigation, watering cattle and as a source for drinking water. And no wastewater is generated in the process since all service water is recycled back into the system. The only waste generated is the spent brine mentioned above.

The machinery that cleans the water is portable and can be set up on a foundation of crushed gravel and wood, so site reclamation is minimal. It’s an economically feasible solution to the Basin’s problem of excessive discharge water, which could run as high as 1.6 million barrels a day. EMIT and Severn Trent currently are treating the water from 80 wells at a gas production field in Arvada, WY, producing 750 gallons a minute to irrigate hundreds of acres of alfalfa and forage. In addition, water currently is being treated at 11 other gas fields in Wyoming and Montana treating a total of 140,000 barrels per day.

Conclusion

The Higgins Loop technology has proven to be a more effective ion exchange technology than fixed bed and fluid bed systems. The technology efficiently uses resin capacity, requires less regenerant and fresh water, and generates consistent product quality. It offers greatly expanded ranges for use of ion exchange resins and adsorbents in commercial separations.

Traditionally, the most common use for ion exchange technology has been in the residential market, where homeowners want to reduce hardness or improve taste of their tap water.

Another common application has been deionization, used where extremely pure water is required. But as the global wastewater minimization market expands, ion exchange will find growing interest in industrial markets for removal of heavy metals, total organic carbon and a variety of inorganic contaminants from wastewater streams. I

About the Author: Rich Dennis is Separation Products manager at Severn Trent Services, of Fort Washington, PA. Contact: 813-886-9331 or [email protected].