by Steve Leykauf

Alkalinity adjustment in industrial processes has become significantly more costly in recent months due to shortage in caustic soda supply. With domestic demand expected to climb by 10% annually, a tighter supply – and higher caustic soda (NaOH) costs – are expected to continue through next year. This has left caustic soda users scrambling to identify and approve alternative alkalinity agents to meet their water and wastewater treatment needs. A slurry of magnesium hydroxide – Mg(OH)2 – is finding increased use in wastewater neutralization and sludge reduction by industrial facilities, in large part due to the high and volatile pricing of caustic soda. Industries are making a conversion to control costs, while realizing technical benefits inherent in Mg(OH)2 treatment.

Sofix Corp., of Chattanooga, TN, which produces the active ingredients used to coat thermal paper, established a goal of finding a product that provides stable pricing, while delivering better pH control, lower heat of reaction and safer handling. Its process utilizes acids and caustic soda for pH adjustment in the wastewater treatment plant before discharging to the local municipal wastewater collection system. Part of the company's process produces a 29% sulfuric acid that requires neutralization prior to discharge. The acid is pumped into an agitated tank and combined with water and currently neutralized with NaOH to a pH of 7 before being fed into the municipal sewage system.

Trial Results

A field trial was conducted to qualify magnesium hydroxide, commonly known as Milk of Magnesia, as a viable replacement for caustic soda. A pH of 7 to 9 was achieved during the trial (see Table 1). Reaction time for pH adjustment was very good and the heat of reaction was far less with the Mg(OH)2 than with NaOH. Mg(OH)2 to NaOH conversion was 0.75 to 0.79 pounds of Mg(OH)2 for every pound of NaOH previously used on a dry basis.

Sofix's Chattanooga staff was very pleased with the trial results and designed a system consisting of a new bulk tank and chemical feed pump designed to feed Mg(OH)2 and flush all lines upon completion of each batch.

Greater Neutralizing Value

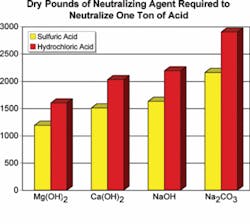

Magnesium hydroxide has a neutralization value that's 37% higher than caustic soda. One gallon of Mg(OH)2 replaces approximately 1.7 gallons of 50% NaOH. Figure 1 illustrates performance of various industrial alkalis. Compare other properties of common industrial alkalis at: http://magspecialties.com/datasheets/FloMag-pdf/FloMag%20-%20Properties%20of%20Industrial%20Alkalis.pdf

null

Cost Savings

Cost Savings Example:

- (1,000 tons/year NaOH) x ($550/ton) = $550,000/year NaOH cost

- (730 tons/year Mg(OH)2 ) x ($400/ton) = $292,000/year Mg(OH)2 cost

- Savings = $258,000/yr

Current magnesium hydroxide pricing delivers savings of $150 or more per ton compared to caustic soda. Each 1,000 tons of NaOH could save $258,000 on an alkalinity equivalency basis. Mg(OH)2 is relatively price stable compared to NaOH. Other cost benefits include:

- Costs to dispose of biosolids/sludge – Creates less sludge volume vs. other alkalis

- Costs for acids – Natural buffering at pH 9 renders pH adjustment with acids unneeded

- Costs for polymers – Mg(OH)2 forms a larger floc particle where solids settling is improved, reducing polymer usage

- Reduced transportation costs – Consuming less Mg(OH)2 means less product to transport

Conclusion

Finally, magnesium hydroxide is safer and more environmentally friendly. The slurry is supplied as a high purity, industrial grade Milk of Magnesia. Mg(OH)2 is non-toxic (when properly used), non-corrosive, non-hazardous and safer to handle than caustic soda. In addition to reduced initial cost, it has a greater pound-for-pound alkalinity contribution, improves biological activity since magnesium is a nutrient, assists in metals removal via precipitation and adsorption, and reduces sludge and the need for its disposal.

Acknowledgments: The author thanks Martin Marietta Magnesia Specialties southeast region manager Darryl Stafford, field representative Aileen Gibson and Sofix for their help on this article.About the Author: Steve Leykauf joined Martin Marietta Magnesia Specialties LLC in October 2006 as a sales engineer for Thioguard® in the U.S. Midwest, working previously in technical sales capacities in the electrical, electronics and telecommunications industries. He lives near South Bend, IN. Contact: 574-277-2237 or [email protected]