by Bill Stapp

Tin is emerging as a cost-effective and environmentally friendly technology to control corrosion. These two case histories demonstrate the power of AS Inc.'s patented technology to treat industrial cooling water as well as drinking water in situations where corrosion was affecting the quality of the water.

No. 1 - Industrial Cooling Water

The Park Central Office Complex in downtown Denver is a 500,000 sq. ft. building with 1,750 HVAC towers. Following a lab evaluation by Puckorius & Associates that indicated a tin-based water treatment program performed well for industrial cooling water, the chief engineer of the complex agreed to participate in a field evaluation in its cooling water system.

At the evaluation's start, AS-8310 – a tin compound, tolytriazole, HEDP, and poly carboxylate polymer – was fed for the first two weeks at twice the maintenance level of 100 ppm. During this time, the HVAC system was operated at 4-5 cycles of concentration on Denver city water.

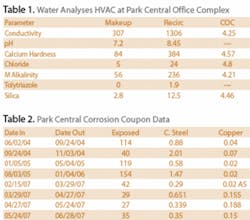

As data in Table 1 show, there was very good correlation in the cycles of concentration, indicating that no deposit formation is occurring.

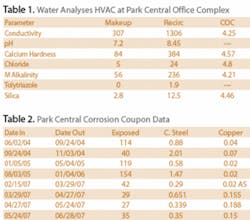

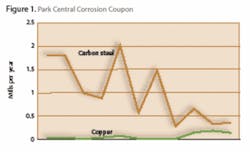

The corrosion coupon data, shown in Table 2 and graphed in Figure 1, clearly indicate that the tin technology treatment was very effective in controlling carbon steel corrosion. Note that the coupons exposed prior to March 29, 2007, were pretreated by the incumbent supplier. Therefore, results aren't like comparing apples to apples, but rather like comparing apples and oranges. Also note that exposure time is a key element in determining the corrosion rate as corrosion is most aggressive when surfaces are fresh and tapers off as the exposure time increases.

As the coupons pictured show, the corrosion produces a minimal effect on the bulk of the surfaces, with corrosion most prominent where the coupons attach to the corrosion coupon holder.

How Does Tin Work?

AS Inc.'s research and discussions with chemical engineering colleagues indicate the tin atom can share electrons and form a barrier that greatly reduces corrosion. Tin also works as a reducing agent and converts ferric (Fe+3) iron to ferrous (Fe+2) iron which is useful to clean up systems and to form a protective iron oxide (gamma iron oxide). Tin-based treatment program residuals are determined through a tracer.

Moreover, tin technology offers several advantages over other commonly used corrosion control water treatments, such as phosphates, molybdates, and nitrites:

• Advantages of tin technology over phosphate-based treatments – Phosphates require calcium to form a protective layer, which, as iron and phosphate deposits, can become a barrier to heat transfer and reduce treatment efficiency. What's more, phosphate is a nutrient which leads to algae growth and results in maintenance cost and monitoring issues. Using tin instead of phosphates removes a nutrient from wastewater streams.

• Advantages of tin technology over molybdates – Molybdates are costly given that effective doses for corrosion inhibition are 40-50 ppm. Effective doses for tin are 2-3 ppm. Use of Molybdate has been banned in Denver because the wastewater treatment plant sludge there is used for land applications which include raising dairy cattle. Molybdate, which interferes with the absorption of copper in cows, was found in the milk supply. To prevent problems with child development, molybdate discharge was banned.

• Advantages of tin technology over nitrites – Unlike nitrites, tin isn't a microbiological-nutrient, and so doesn't cause the maintenance cost and monitoring that a nutrient creates. Bacteria metabolize nitrites into nitrates which render it ineffective as a corrosion inhibitor. It also creates a need for biocide use, and recharging the system with additional nitrite to control corrosion. Thus the cycle begins again and without careful attention, corrosion control can be sacrificed.

• Environmental implications – Tin is an effective green technology – worth mentioning to today's increasingly environmentally conscious consumers, public officials and representatives, and business partners. Tin isn't a constituent listed on NPDES permits. At the levels used in AS Inc.'s applications, tin is environmentally safe for use not only in industrial cooling water treatment but in drinking water treatment programs as well. The tin levels AS Inc.'s technology uses are vastly smaller than tin levels in canned food products consumed daily by millions around the globe. AS-8150 and AS-8105 are NSF 60 certified, approved for application at levels up to 1 ppm and 10 ppm of product, respectively.

No. 2 - Drinking Water

St. Paul, MN, has been treating its potable water with AS-8150 for seven years to successfully reduce lead release. Prior to using AS-8150, St. Paul was under a Minnesota State Health Department mandatory lead service line replacement (LSLR) order. Since introducing AS-8150, St. Paul has passed every round of Lead and Copper Rule sampling and the mandatory LSLR order has been rescinded. Since late 2005, St. Paul has been placed on reduced monitoring status.

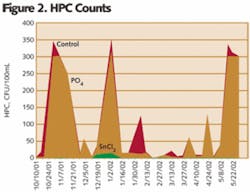

Figure 2 is from a pipe loop study done by Elizabeth Esbri Amador, a University of Minnesota graduate student. The study focused on lead release as well as on the propensity to grow bacteria. The lead release aspect showed PO4 to be slightly more effective; however, bacterial growth was significantly greater with PO4.

Microbiological Growth

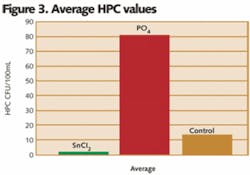

As shown in Figure 2, orthophosphate increased the bacterial colony forming unit (CFU) count – i.e., heterotrophic plate count (HPC) – over the control value, while the stannous chloride treated loop had the lowest CFU value.

As shown in Figure 3, orthophosphate is the most predominant color (red) on the graph, and stannous chloride (green) has the least amount of area on the graph.

Conclusion

As the above case histories demonstrate, AS Inc.'s tin technology, AS-8310, provides excellent mild steel corrosion control. Besides being effective, tin-based treatment programs can be formulated to be highly competitive with less environmentally sensitive non-tin-based programs.

Tin-based treatment offers additional advantages as well: It can improve heat transfer, due to cleaner surfaces creating lower scaling potential, and it can significantly reduce microbiologically induced corrosion (MIC).

Tin-based treatments are applicable in open recirculating systems such as cooling towers as well as potable water systems, especially ones where lead pipes may require treatment or replacement so that drinking water may remain safe.

Acknowledgments: The author would like to acknowledge the following people for their help in conducting these studies and in reviewing this data: Paul Puckorius, president and CEO, Puckorius & Associates Inc.; Clayton Wright, chief engineer, Park Central Office Complex; Ken Allen, former chief engineer, Park Central Office Complex; Bob Hess and Dave Puckorius, Puckorius & Associates Inc.; Ray Hozalski, Ph.D., civil engineering professor, University of Minnesota; Elizabeth Esbri Amador, graduate student, University of Minnesota.About the Author: Bill Stapp is president of AS Inc., a water corrosion specialist based in Santa Rosa, CA. Contact: [email protected] or www.asi-corrosioncontrol.com