By Terry Robbins, John D. Harrelson and Debora Burgess

To tackle odor issues caused by conditions in an 8-mile wastewater force main in a sensitive suburban environment, the City of Rock Hill, S.C., and BetzDearborn implemented a chemical treatment program that involved the adaptation of a system for blended, proportional product feed.

The strong malodorous smell of H2S was generating complaints from neighboring communities. Eliminating these complaints was the number one objective of the odor control program.

Most H2S in force mains is generated by sulfate-reducing bacteria under anaerobic conditions. Such conditions may exist in local slime layers in force main pipelines. The bacteria use chemical organic substrates to generate energy and to make new cells. As part of the energy and cell making process, sulfate becomes the electron acceptor and is reduced to H2S. This process can generate large quantities of H2S. Donor material may consist of a wide variety of organic substances commonly found in wastewater from dwellings.

In order to identify and quantify the odorous compounds in the collection main, field testing was done using water and air samples taken from several points in the distribution system. The samples were tested with a Hach test kit, Drager tubes or an Industrial Scientific air meter.

Enzymatic inhibition of the generation of hydrogen sulfide and direct scavenging of existing H2S were accomplished through the use of a combined product program. The program involved two BetzDearborn ProSweetRegistered products which were fed into the WildCat lift station influent ahead of the baffle section.

The initial ProSweet product fed was a hydrogen sulfide scavenger. After several days of this treatment program, an enzyme product was introduced and fed at the same location. This product was designed to inhibit the production of H2S. This inhibition is thought to occur by either repair of the microbial cell membrane sufficiently enough that sulfate is not transported across the membrane, or by inhibition of the metabolic pathway in the organism's use of sulfate as an oxygen acceptor. Both phenomena may occur.

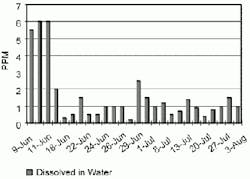

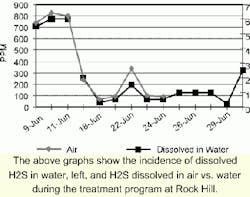

Performance testing conducted in June 1999 revealed that a greater than 83 percent reduction in H2S in the air space and water of the force main had been obtained within a two and one-half week period since treatment start-up. At the beginning of the program, the H2S level in the force main water was 6.0 ppm. The level quickly was reduced and maintained at less than 1 ppm. Air space levels of H2S were initially in the 830 ppm range. This was lowered to less than 100 ppm.

When BetzDearborn was given an opportunity to resolve these odor problems, the plant was at the point of deciding whether to seek approval of capital expenditures for better mixing equipment. The success of the Prosweet program eliminated the need for capital cost equipment. The program was easily set up and fed into the lift station. A metering pump and a tote tank of chemical were all that was needed.

Since the trial start-up, no further community complaints have been received. Another benefit to the municipality has been the reduction in labor costs. Program costs are much lower than those associated with the inorganic magnesium hydroxide program that was used previously.

The daytime temperatures during the trial ranged between 80-90° F. The H2S readings continue to be low to nonexistent. Corrosion coupons were installed as part of the monitoring service. The ProSweet program feed rate was based upon total water flow of 10 MGD. The enzyme portion of the program was fed at a rate of 0.4-1.0 ppm and the H2S scavenger was fed at a rate of 2.0-5.0 ppm.

During a three-week period in June and July 1999, there were no odor complaints. The chemical feed has been regulated to provide the optimum results from both the odor control and the corrosion control aspect of the program.

About the Authors:

Terry Robbins is Project Engineer, Technical Marketing, for BetzDearborn. John D. Harrelson is Account Executive, Carolinas District, for the company. Debora Burgess is Maintenance Superintendent, Rock Hill Utilities, City of Rock Hill, S.C.