Automatic DO Control Pays Off at Wastewater Plant

By Howard M. Wexler

The Town of Montague, MA, recently installed a system to automatically control dissolved oxygen levels at its conventional activated sludge wastewater treatment plant. The plant aeration system had been manually controlled, and the upgrade resulted in significant energy savings.

The Montague plant is designed for an average 24-hour hydraulic loading of 1.83 mgd and a peak five day biochemical oxygen demand (BOD5) loading to the aeration tank of 3,836 pounds per day. In 1998 the average 24 hour plant effluent flow was 1.03 mgd, and the average BOD5 loading to aeration was approximately 3,000 pounds per day. Peak and minimum hourly BOD5 loading to aeration was approximately 4,500 and 1,000 pounds per day, respectively.

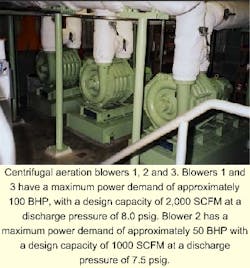

The plant uses coarse bubble diffusers in conjunction with centrifugal blowers to provide air flow and maintain dissolved oxygen for the mixed liquor in the aeration tanks.

There are a total of three aeration blowers, two are rated for 100 input brake-horsepower (BHP) and one for 50 BHP. When the plant was upgraded to secondary treatment in the early 1970's, three 100 BHP blowers were provided. In the early 1980's, when plant loading decreased significantly, the town modified the impellers on one of the blowers to downgrade its capacity.

As of 1998 all three blowers were constant speed. Air flow could be adjusted by manually throttling the blower inlet valves, but this was not practical since the oxygen demand loading to the aeration tank varied throughout a 4:1 range in a typical 24-hour day. Furthermore, the plant is only manned eight hours a day.

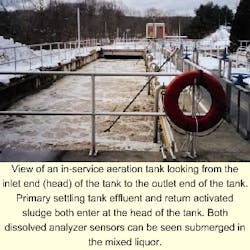

Air flow was manually adjusted at an average frequency of once per week or less. Consequently, the dissolved oxygen concentration in the aeration tank mixed liquor could range from 0.1 (essentially zero) to nearly 8.0 milligrams per liter (mg/l) throughout a 24-hour day.

Due to the high energy and cost implications of allowing the dissolved oxygen concentration to reach above 2.0 mg/l, plant personnel did attempt to reduce air flow. Their efforts, however, at times caused excessively low dissolved oxygen concentrations, particularly during above average oxygen demand loading periods, which occurred for at least 12 hours per day. During these periods dissolved oxygen concentrations would typically drop down to measured values of 0.1 mg/l and create anoxic conditions in the aeration tanks.

As a consequence, the plant often received odor complaints from adjacent residents, saw high concentrations of filamentous organisms, low settling rates, high Sludge Volume Index (SVI), and sludge bulking. Often operating personnel had to place both final settling tanks in service and use polymer as a coagulant to maintain adequate capture efficiency of total suspended solids (TSS) in the final settling tanks. In addition, chlorination of the return sludge was necessary to keep filamentous populations under control.

Robert Trombley, Superintendent of Water Pollution Control for the Town of Montague, realized that something had to be done to keep the tank from turning anoxic. Furthermore, the fix could not require excessive air flow or be beyond the town's limited budget.

In 1998, Trombley contacted the local electric utility, Western Massachusetts Electric Company (WMECO), a subsidiary of Northeast Utilities, to sponsor an Energy Analysis Survey (EAS) to tackle the problem. Northeast Utilities has promoted energy conservation within its service area for many years by providing incentives to its customers to reduce demand and conserve energy. In November 1998, WMECO commissioned Bricar Engineering to conduct an Energy Analysis Survey.

Bricar conducted the survey from June 1998 through October 1998. The five months were analyzed to determine the existing BOD5 loading to the aeration tanks, and the BOD5 removal in the aeration tanks and final settling tanks. June 1998 was used as the initial month because significant additional BOD5 loading began to enter the plant from a new industrial customer.

Bricar evaluated replacing the existing coarse bubble diffusers with fine bubble diffusers, downsizing the aeration blowers and providing an automatic dissolved oxygen control system. The oxygen transfer efficiency of fine bubble diffusers is two to three times more efficient than coarse bubble diffusers and would have significantly reduced the required air flow. However, the energy and cost savings were insufficient to justify the large capital cost.

Next, Bricar evaluated the alternative of continuing to use the coarse bubble diffusers but in conjunction with a dissolved oxygen control system that would automatically vary air flow through the diffusers in order to maintain a dissolved oxygen setpoint, regardless of the varying BOD5 loading to the aeration tanks.

The proposed system consisted of a new variable frequency drive and premium efficiency motor for each blower, a new dissolved oxygen analyzer for each of the two aeration tanks, a new control panel and associated electrical work.

System Comparisons

In the event the automatic dissolved oxygen control system was not implemented, the town would be forced to significantly increase and maintain constant air flow to the aeration tanks, sufficient to satisfy the peak hourly oxygen demand and still maintain a minimum dissolved oxygen concentration of 2.0 mg/l.

The peak hourly air flow requirement was computed for the average 24-hour day analyzed during the five month period of record. The computed value was 4,123 standard cubic feet per minute (SCFM). Based on the existing blower performance curve and the system pressure conditions, the required total brake-horsepower was 188 BHP, total electrical horsepower was 208 EHP, and the total electrical kilowatts was 156 KW for the peak hourly airflow. This represented the continuous electrical demand that would have to be maintained to achieve a minimum dissolved oxygen concentration of 2.0 mg/l over the average 24-hour day. It would have resulted in power consumption of 1,366,560 KWH/year.

As part of the study, an analysis was made based on providing an automatic dissolved oxygen control system and new premium efficiency motors. The control system would adjust air flow by varying the speed and BHP of the operating blower or blowers and automatically switch from one blower operation to two blower operation, or vice versa, as the demand for air changed.

Based on the average BOD5 removed of 2,626 pounds per day, and the average associated air requirements during the study period, the average hourly power need demand, with the dissolved oxygen control system in operation, was estimated at 98.75 KWH, or for a total annual energy consumption of 865,050 KWH/year.

System Implementation

Based on the results of the EAS, WMECO agreed to provide the Town of Montague with an energy conservation rebate incentive. In early 1999, the town commissioned Bricar Engineering to provide design, construction management, system startup and training on the Automatic Dissolved Oxygen Control project.

In September 1999 the completed project was placed into service. Initially, the plant operators used a dissolved oxygen setpoint of 2.0 mg/l, however, the setpoint was reduced to 1.5 mg/l in order to achieve maximum energy efficiency and cost effectiveness. Furthermore, Trombley is considering reducing the setpoint even lower. Since the startup of the DO control system, there has been no problem with odors and plant performance has been high.

The installed cost for the new system was $115,000, which was within five percent of the estimate provided during the EAS phase of the project.

The aeration blowers uses used approximately 85 percent of the total energy consumed by the Montague Wastewater Treatment Plant. Based on monthly utility billing records for a one year period following the startup of the DO control system, the annual energy consumption from January 20, 2000, through January 23, 2001, was 826,560 KWH/year. Therefore, the approximate energy consumption attributable to the aeration blowers was 702,576 KWH/year, significantly lower than the EAS estimate. This is primarily due to two factors. First, the actual BOD5 removed in secondary treatment was only 2,360 pounds per day compared to 2,626 pounds per day during the EAS study period. Second, the fact that the dissolved oxygen setpoint used for the EAS was 2.0 mg/l, whereas the dissolved oxygen setpoint actually used during the year following system startup was lower.

Summary

On the basis of an average of 2,626 pounds of BOD5 removed in secondary treatment and a dissolved oxygen setpoint of 2.0 mg/l, When when compared to the "baseline" alternative, the Town of Montague is currently saving approximately $41,475 per year in electric utility costs. Saving is based on the utility rates that went into effect on January 1, 2001 ($.0827 per KWH). This represents slightly greater than 30 percent of the "baseline" utility bill.

Furthermore, the fact that the dissolved oxygen concentration in the mixed liquor is maintained at a constant level creates more steady state process conditions. More steady state generally translates to better and more consistent process performance, and this case is no exception.

During the 12 months prior to implementing the automatic dissolved oxygen control system, the average plant effluent BOD5 concentration was 19.2 mg/l. During that same period the secondary treatment removal efficiency for BOD5 was 93 percent. For the 12 months following the implementation of the automatic dissolved oxygen control system the average plant effluent BOD5 concentration was 12.2 mg/l. The secondary removal efficiency for BOD5 was 96 percent. Effluent quality, in terms of total suspended solids concentration, also improved several milligrams per liter and became more consistent.

Although the improvement in plant effluent quality was not dramatic, improved process performance and stability are typically non-energy related benefits to automatic dissolved oxygen control at wastewater treatment plants.

About the Author:

Howard M. Wexler, PE, is General Manager of Bricar Engineering Associates, LLC, a company located in Bristol, CT, specializing in power reduction and energy conservation at water and wastewater facilities. Wexler was the Project Manager and Engineer on the Montague, MA, Wastewater Treatment Plant project.