Hybrid Aeration Process Provides Power Savings

By George Smith

In most wastewater treatment plants, aerating activated sludge systems consumes the majority of the plant's power. Thus, the efficiency of the aeration system becomes a major factor in designing an economically operated plant. Too frequently, however, consideration is only provided for the efficiency of the aerator device while the impact that the overall design of the system has on aeration efficiency is neglected.

A new "hybrid" treatment plant design has demonstrated substantial aeration power reduction. The system features reactors in series, using mechanical aerators in first stage reactors and fine bubble diffusers in the second. Compared to the power draw of a conventional fine bubble aeration system, the hybrid system can reduce aeration power draw significantly.

The hybrid blend of aerators is unusual. Traditional activated sludge designs have a single type of aeration equipment which usually ensures one-source responsibility for both equipment and process. With the hybrid design, the equipment supplier needs to have considerable background experience on two widely varying types of aeration devices and the knowledge of how these differing devices can be merged together into one compatible system.

Process Aeration EfficiencyBased upon numerous studies conducted under a wide variance of conditions, there can be little dispute that the fine bubble diffuser device easily has the highest oxygen transfer efficiency in clean water. Test studies conducted on full-scale tanks, using membrane discs or ceramic domes on a full-floor grid system, have shown a clean water efficiency of 7.2 lbs/eHP-hr under standard conditions. Mechanical aerators usually have an efficiency in clean water of less than half of this a typical figure being 3.2 lbs/eHP-hr.Although the efficiencies of the devices seem far apart, they are more comparable under mixed liquor operating conditions when alpha factors are taken into account. For fine bubble diffusers, the major component in wastewater effecting alpha is surfactants. Surfactants have a highly significant impact on the gas-liquid interface, decreasing the surface tension of the interface and making transfer more difficult. The degree of difficulty increases as the bubble size gets smaller. For most aeration designs, the adage is "the finer the bubble, the lower the alpha." The alpha factor used in many fine bubble activated sludge systems is as low as 0.5; this results in a process aeration efficiency (PAE) that is already reduced to half of the clean-water efficiency.

Mechanical aerators react to surfactants differently. Surfactants help produce smaller water droplets, increasing the available surface area for oxygen transfer. Thus, in activated sludge systems using mechanical aerators the alpha factor can actually be above 1.0.

Surfactants are broken down in the activated sludge process and their influence is reduced with their extent of time within the process. In an elongated plug flow tank, surfactants would be more prevalent at the beginning and less at the end. Thus, for a plug flow tank using fine bubble diffusers, the alpha could be as low as 0.25 at the front end and as high as 0.85 at the outlet. The sludge age of the system is also a factor, with the fine bubble alpha factor being lower for the short sludge age and higher for the longer sludge age.

In studies conducted at a plant using mechanical aerators in long plug flow tanks, an alpha factor of 1.2 was measured at the front end while 1.0 was measured at the outlet. Unlike fine bubble, the best PAE for mechanical aerators is at the front end of the process.

DO ConsiderationsThe DO (dissolved oxygen) concentration used in the aeration design has another large impact on the PAE of the aerator device. For a conventional aeration tank, the DO level most frequently selected (and usually required by regulatory agencies) is 2 mg/l. Because of the initial higher demands at the front end of long plug flow tanks, tapered aeration (higher aerator delivery rates followed by gradually reduced delivery rates) is used to keep a 2 mg/l DO level throughout the entire tank. It was believed that keeping the DO at this level was necessary to prevent process upsets.Recent studies, however, advocate the compartmentalization of long plug flow tanks and indicate that better process performance can be obtained when the DO levels are kept at zero in the initial stages. These studies show that a biomass with better settling properties can be established when the aeration tank environment alternates from a low DO zone to a high DO zone.

Separate reactors with zero DO conditions for the first half and higher DO conditions for the second half does improve the PAE of the system. The transfer rate of the aerators operating in the oxygen deficit tanks is 20 percent higher. In addition, conditions are set up for simultaneous nitrification-denitrification. The denitrification rate in a zero DO aeration reactor can be as high as 80 percent without internal recycle and the oxygen recovered through denitrification adds another 15 percent savings in oxygen delivery requirements.

Vertical Loop ReactorsBy definition, zero DO aeration reactors or aeration tanks operating with oxygen deficit conditions are "aerated anoxic tanks." While typical non-aerated anoxic tanks use only a small part of the total biological volume, usually 20 percent of the total or less, there are more process advantages and aeration power cost savings when the aerated anoxic tanks are designed for at least half of the total biological volume.The ideal aerated anoxic tank is a looped reactor with an uni-directional flow pattern. It is important in the design of an aerated anoxic tank to maintain an oxygen deficit environment under all load conditions. During low conditions, the tank cannot be over-aerated because of mixing requirements. The looped reactor has the benefit of being a more efficient mixing regime. The mechanical aerators used with looped reactors have the benefit of alternating points of oxygen delivery allowing simultaneous nitrification-denitrification to be maximized.

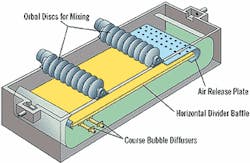

The Vertical Loop Reactor (VLR) is this type of ideal aerated anoxic looped reactor. The VLR is an oxidation ditch "flipped over" on its side. Disc aerators surface mechanical aerators provide the oxygen delivery and the mixing; supplemental coarse bubble air is provided in the lower chamber.

The VLR is a recent aeration system development. The first VLR plant was started up in Hohenwald, TN, in 1986. Over 30 VLR plants have now been constructed or placed into operation, ranging in size from 0.5 mgd to a 43-mgd plant in Bangkok, Thailand.

Hybrid BlendWhile the VLR had strategic advantages in being used as aerated anoxic tanks, it does not represent any improvement over fine bubble aeration in the last tanks where the DO levels are kept high. Since both VLR and fine bubble use deep basins with a rectangular footprint, it would seem only logical to merge these reactor systems together as one process train and see what energy advantages are available. While the process mode of reactors in series would remain unaltered (the aerated anoxic VLR tanks still would have 50 percent of the total volume) the magnitude of the energy savings with this hybrid concept is surprisingly high.Upfront mechanical aerators make sense: this is where they would have their highest alpha factor. Delivering about half of the oxygen under zero DO conditions also make sense this would further improve the process transfer efficiency while also recovering oxygen through denitrification. Using fine bubble diffusers in the second half of the system is equally logical. The PAE of the fine bubble diffusers in the second half of the process due to improved alpha (and reduced diffuser fouling considerations) is about twice as high as it would be in the front half of the system.

For a 16-mgd plant, designed with a 10-day sludge age, the expected power draw of a conventional fine bubble system would be 774 eHP. This is based upon a 2 mg/l operating DO and an overall AOR of 2376 lbs/hr. The SOR of the system, using a FCF of 0.40, would be 5940 lbs/hr. With a fine bubble SAE of 7.2 lbs/eHP-hr, the power draw would be 840 eHP.

For the same plant, with aerated anoxic VLR tanks for the first 50 percent of the process, the AOR would be reduced from 2376 lbs/hr to 1960 lbs/hr through denitrification - with 910 lbs/hr being satisfied in the VLR tanks and 1050 lbs/hr in the fine bubble tanks. The FCF for the discs in VLR tanks would be 0.98 and the SOR would be 929-lbs/hr. Power draw of the discs, using a SAE of 3.2 lbs/eHP-hr, would be 290 HP. The FCF of the fine bubble would be 0.56 and the SOR would be 1875 lbs/hr. Power draw, with a SAE of 7.2 lbs/eHP-hr, would be 260 eHP. Total power draw would be 550 eHP.

This unique blend of aerated anoxic loop reactors in front of aeration cells with fine bubble diffusers is entitled, "VertiCel" the name being derived from the Vertical Loop Reactors used as the upfront aerated anoxic loop tanks and the fine bubble Cells used in the second half of the system.

The power savings features of the VertiCel can be summarized as follows:

The alpha factor of the fine bubble diffusers are optimized by using them in the second half of the system.

- The alpha factor of the mechanical aerators is optimized by using them in the first half of the system.

- Keeping the first half of the system under aerated anoxic conditions provides substantial oxygen recovery through denitrification.

- Delivering oxygen under zero DO conditions in the first half of the system substantially benefits the PAE of the aerator device.

The VertiCel system was developed by USFilter's Envirex Products. The systems can be designed for new plants, or for upgrades of existing fine bubble plants. The VertiCel is also ideal for BNR upgrades. WW/

About the Author: George Smith is manager of the Orbal/VLR product line at US Filter/Envirex Products. He has six patents in the wastewater treatment field, including two on the VLR process.