For many years water utilities and contractors had only one option when tapping a pressurized water line - to use a configuration involving a flanged tapping valve and a flanged tapping sleeve. Unfortunately, there were drawbacks to using these types of connections.

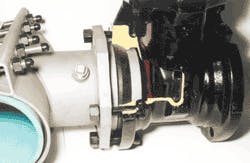

After discussing the challenges involved with a number of utilities and distributors, PowerSeal Pipeline Products Corporation of Wichita Falls, TX, developed a new tapping sleeve. Its Model 3490MJ stainless steel tapping sleeve with mechanical joint outlet allows for the use of standard, less expensive mechanical joint resilient wedge gate valves when tapping a pressurized line. This virtually eliminates the need to use specialty tapping valves. The result is reduced valve and accessory inventory and cost savings of up to 30 percent over that of a typical tapping valve and sleeve configuration.

First introduced in 1998, the 3490MJ tapping sleeve has been installed approximately 2,500 times throughout the United States. It can be used on a variety of pipe, including cast iron, ductile iron, C900 and C909 PVC, Cl-160 and Cl-200, SDR-26 and 21, asbestos cement and HDPE.

The shell is constructed of heavy gauge type 304 18-8 stainless steel, which provides tensile strength at less weight than a comparable cast iron sleeve and lessens the possibility of corrosion. This results in lower installation costs and less stress on the pipe. In addition, all 3490MJ tapping sleeves have an over-sized inside branch diameter, which ensures maximum flow and allows for use of full-size shell cutters.

Product features include drop in bolts and full circle mat gaskets, which maintain 360 degree contact and full support of the pipe, thereby acting as a repair clamp should the pipe break during or after the tapping operation. The branch gasket is the primary seal and is achieved both mechanically and hydrostatically. The mat and branch gaskets maintain their position within the pressure vessel by means of five welded stainless steel retaining rings that prevent extrusion or cold flow.

"We like the way the retaining rings help secure the tapping sleeve gaskets. The mechanical joint outlet gasket is also thicker and works really well to ensure a tight seal. This is what makes the mechanical joint tapping sleeve a better alternative than having to use a flanged tapping valve," said Danny Griffin, Water & Sewer Crew Leader for Jacksonville Electric Authority in Jacksonville, FL.

The tight seal provided by the gaskets and the stainless steel retaining rings welded to the shell also allow the tapping sleeve to withstand higher working pressures.

"We have areas where the pressure can reach 250 psi and we don't allow for any other type of sleeve besides the 3490. It has a great ability to seal against high pressure and withstand that pressure over time," said Donovan Larson, Senior Project Engineer for Consolidated Public Water Supply District Number C-1 in Barnhart, MO.

Inventory Reduction

Inventory reduction and hard cost savings were the main reasons PowerSeal developed the new tapping sleeve. A number of its customers in the water works industry had a desire to reduce operating and investment costs associated with the installation, maintenance and repair of pressurized water lines. Specifically, they wanted to reduce their inventory of pipeline accessory products.

"Since the 3490MJ Tapping Sleeve takes a standard valve, it helps reduce inventory. This is a big factor when working with a large municipality, where the installation of more than 500 valves per year is not uncommon. It makes a difference not to have to purchase and store separate tapping valves. And since a tapping valve is more expensive, you do realize some hard cost savings." Larson said.

Ease of Installation

In addition to reducing inventory, the 3490MJ also helps streamline the tapping sleeve installation process. No welding or caulking is required, and the only tool needed for installation is a standard wrench.

"It's simplicity and ease of installation is a plus. It's easier for one person to install on small diameter pipes, and 2 people can handle it on pipes of larger diameters. It's just much easier to put together, since there are not a lot of parts. And the mechanical joint is more forgiving, meaning it can take a little more ground movement while still remaining watertight," said John Keller of Viking Supply Company in Florence, KY.