Users of chlorine now regulated by the newly created 2003 International Fire Code and the 2003 Edition of the Uniform Fire Code are no longer required to have a scrubber when storing or using 150-lb cylinders or one-ton containers of liquefied chlorine gas.

For indoor and outdoor storage, the need for a scrubber is eliminated when:

1. Chlorine cylinder valve outlets are equipped with gas-tight outlet plugs or caps.

2. Where approved containment vessels or containment systems capable of fully containing or terminating a release are available or that are capable of being transported to the leaking cylinder, container or tank.

For indoor and outdoor use, the need for a scrubber is eliminated when:

1. An approved automatic-closing fail-safe valve is located immediately adjacent to the cylinder valves. The fail-safe must close when gas is detected at the permissible exposure limit (PEL) by a gas detection system monitoring the exhaust system at the point of discharge from a gas cabinet, exhausted enclosure, ventilated enclosure or gas room.

2. Where approved containment vessels or containment systems capable of fully containing or terminating a release are available or that are capable of being transported to the leaking cylinder, container or tank.

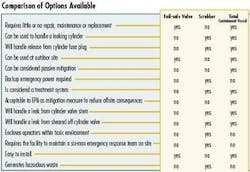

Plant operators have found that fail-safe valves and containment vessels require little or no maintenance, repair or replacement.

A fail-safe valve is typically described as a 1/4 turn ball valve that is spring loaded, always fails in a closed position and does not rely on any electrical power or backup emergency power to close the valve.

Unmanned sites located in densely populated areas are especially in need of a system to process chlorine from cylinders or ton containers that will release little or no chlorine gas to the surrounding community.

Total containment vessels used for processing chlorine from a cylinder or ton container that is enclosed within the vessel can reduce the worst-case offsite release of toxic gas by 97 percent.

Sites located within sparsely populated areas may find the cost of installing a scrubber system or total containment system to be out of the question because of budget constraints. The new codes allow these sites to use the less expensive automatic closing fail-safe shutdown valves located immediately adjacent to the cylinder valves. The fail-safe valves must close when a gas detection system detects a release at the permissible exposure limit.

All sites storing cylinders or ton containers must have available containment vessels or systems capable of fully containing or terminating a release from a leaking cylinder or container.

If the emergency containment vessel is not located at the site, it must be capable of being transported to the site of the leaking cylinder. A trailer mounted emergency containment vessel would typically be transported to the site by the emergency responder.

Communities with multiple sites need have only one emergency vessel available to handle leaking cylinders or containers. Although locating an emergency vessel at every site will provide added safety.

The emergency vessel must be designed to process the entire contents of the leaking cylinder or container at the treatment site to prevent transporting a leaking container.

Small communities may, through association with others, share the cost of a containment vessel system, trailer mounted so as to allow compliance at a lower cost.

Total containment vessels satisfy the definition of a treatment system in the codes because, once contained within the vessel, the total contents from the leaking cylinder or ton container can be put into process at the site at a safe controlled rate.

As in all cases related to fire codes, the local fire department should be consulted to determine their requirements.