By Paul F. Boulos

Rapid population growth and the deterioration of aging infrastructures are overtaxing sewer systems worldwide. The usual localized, “find and fix as you go” approach is not cost-effective or reliable, and may not even improve overall collection system performance. For alterations and improvements to these systems to be effective and economical, good engineering decisions based on sound analysis procedures will be required. There are guidelines and best practices manuals for sewer renewal planning (e.g., WEF, ASCE, WRc) but without automated software support, their practical application poses massive data processing and management challenges.

Recent technological advances in GIS, dynamic modeling and high resolution closed-circuit television (CCTV) allow wastewater utilities to better predict when a sewer pipe is going to fail and quantitatively assess and evaluate the costs and benefits of alternative renewal options.

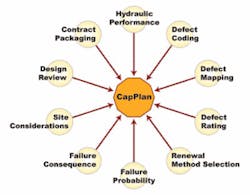

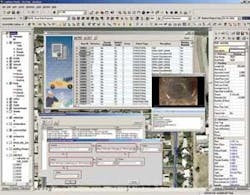

CapPlan, a new product from MWH Soft (Broomfield, CO), seamlessly integrates the industry-standard USEPA SWW5 hydraulic sewer network simulator with ESRI ArcGIS geospatial technology and sophisticated decision tree algorithms. The product gives wastewater engineers new power to process sewer inspection and modeling data, identify pipes with the greatest risk of hydraulic deficiencies and/or structural failure, generate a prioritized list of all pipes requiring rehabilitation, and propose appropriate rehabilitation methods or replacement.

Armed with this data, wastewater utilities can create real, flexible, and prioritized rehabilitation plans that will improve sewer system performance and work within their existing capital improvement budgets.

Assessing Condition Level

CapPlan is a comprehensive decision support tool that helps wastewater utilities determine sewer rehabilitation needs and prioritize projects for short- and long-term benefits. The software is used to assess both system structural (and O&M) condition and the probability and consequence of failure for each asset.

System structural condition is determined through collection system evaluation studies using CCTV data. Based on these studies, defect coding can be assigned for each asset (e.g., based on NASSCO/PACP, WRc, or other defect standards) in order to describe internal sewer pipe conditions with a pre-determined grading system.

Coded and rated CCTV data and hydraulic modeling results are sorted and used as the basis for creating the decision tree that guides the sewer planning process and generating the list of sewer segments requiring rehabilitation prioritized by urgency. To meet the goals and financial capability of the rehabilitation program, the sort is based on the utility’s own criteria. The decision-tree determines the most cost-effective methodology for completing the rehabilitation of each segment.

The decision tree is a series of tests to determine whether to leave alone, rehabilitate or replace a given sewer pipe displaying one or more major defects or multiple minor defects. The decision process normally considers all factors required to select the best rehabilitation methodologies, including hydraulic capacity needs; methodology limitations; physical pipe characteristics (e.g., age, diameter, material); surface restoration; unit costs; length of point repairs to total length of segment; and so on.

In the decision tree flowchart example with this article, the first test checks the hydraulic capacity of the pipe. If capacity is insufficient, the pipe will be replaced. The next test checks the number of open-cut point repairs required to rehabilitate the pipe. If this number is greater than one repair per 100 feet, the pipe will be replaced. Another test calculates the length of minor and major defects. If this length is greater than 75% of the length of the pipe, the pipe will be fixed by point repair and lining of the entire length of pipe. Otherwise the requisite combination of point repair and partial lining will be effected.

Risk of Failure

Assets can also be ranked according to probability of failure. These odds can be based on predictive deterioration, failure history and CCTV data. The data is described as number of collapses per mile per year for various pipe materials and diameters as well as number of blockages per mile per year as a function of pipe material and age.

Using these predictive deterioration curves, an additional weighting factor can be assigned to each pipe in the system. These curves also lay the groundwork for future predictive analysis and “what-if” scenarios that assume rehabilitation is not applied.

Consequence of Failure

Consequence of failure can depend on a number of pipe attributes, including depth, number of connected customers, and proximity to critical facilities. Consequence of failure scores of various pipeline assets can be expressed in any user-desired scale, such as high, medium and low impact.

As municipal GIS and modeling systems become more advanced, performing these consequence calculations has become more straightforward. Users can select a land-use or appropriate parcel layer within the municipal GIS, then compute distance from critical facilities (rivers, wetlands, hospitals, schools, manufacturing, high density housing, etc.) to determine the consequence value for each pipe. Other factors, like depth or customers served, can be determined from a hydraulic model or GIS and applied to the consequence in an additive manner.

Total Condition, Risk Levels

Assets most critical to system operation will normally rate higher on the consequence scale; assets in poorer condition will have a higher probability of failure. The risk of each asset is calculated as the product (multiplication) of its probability and consequence of failure. In short, assets with the greatest risk should receive the most attention.

Once the risk assessment for each pipe in the system is complete, it can be viewed within the GIS together with a rehabilitation method from the decision tree and rehabilitation costs to further rationalize the rehabilitation plan.

Capital Improvement Plan

A critical part of any capital improvement plan is presenting and selling it to administrators, elected officials, and other non-technical stakeholders. Implementing such recommendations is expensive, and approvers crave supporting documentation and options. With a well-laid-out plan that incorporates current and predictive conditions and the risk and consequence of failures, wastewater utilities are well-positioned to receive the support they need to keep their sewer systems operating properly and cost effectively well into the future. WW

More Information

- Visit www.mwhsoft.com – CapPlan™ software for building a comprehensive sewer renewal plan

- Visit www.epa.gov/owm/assetmanage/ – The US Environmental Protection Agency web portal for sewer system asset management

- Visit www.nassco.org – National Association of Sewer Service Companies

About the Author:

Paul F. Boulos is the President, COO and Director of MWH Soft (Broomfield, CO). An international expert in water resources engineering, Dr. Boulos has written over 200 articles and nine books, and has received a range of awards from national and international scientific and engineering societies, government and research organizations and NGOs. Among these honors are technical awards from the American Society of Civil Engineers, the American Water Works Association and the US Environmental Protection Agency. In early 2008, he was awarded Honorary Diplomate (Hon.D.WRE) status by the American Academy of Water Resources Engineers, the Academy’s highest honor. He can be reached via email at [email protected].