By Barbara Martin and Elizabeth Pyles

Maintaining disinfection within the distribution system is vital to public health and a priority for all water systems. Utilities must balance the need for adequate disinfection with the ability to maintain sufficient water quality to meet regulatory requirements, such as disinfection by product (DBP) limits. The application of chloramines as a residual disinfectant has been an effective DBP rule compliance strategy for some utilities. Chloramination, however, has presented several significant challenges for others.

One of these challenges is nitrification, a process by which ammonia is converted to nitrite (NO2-) and then nitrate (NO3-) by naturally occurring bacteria. Systems using chloramines in warmer areas, and those with higher water age, will experience some level of nitrification. Nitrification can lead to a rapid degradation in distribution system water quality, including a loss of disinfectant residual, increased heterotrophic plate count numbers, and an increased potential for corrosion as alkalinity is consumed. Because of this, a nitrification event calls for immediate action, typically resulting in systems flushing the affected area with large quantities of water.

An additional challenge occurs when a system needs to blend chlorinated and chloraminated water in the distribution system. Mixing chlorinated and chloraminated waters can result in ineffective disinfection conditions, due to the formation of di– and tri-chloramines or the occurrence of break point chlorination. Most systems facing this challenge will elect either to segregate the system into distinctive disinfection zones, prohibiting blending, or to provide booster chloramination, which can severely limit a utility’s flexibility in how it is able to utilize its distribution system to provide water to its customers.

Johnston County Public Utilities faced this challenge when making the decision to purchase chlorinated treated water to supplement its existing chloraminated supply, to meet the demands of its expanding rural service area.

Distribution System Challenges

Located in a fast growing area outside of Raleigh, NC, Johnston County Public Utilities provides service to its rural customers through 1600 miles of pipeline. In some areas of the distribution system, water age can be as high as 14 days. To comply with DBP rule requirements, monochloramine was used to maintain distribution system disinfection, which posed some challenges to the utility. During the warmer months, nitrification would occur in areas of the distribution system with a higher water age. When this occurred, the system was flushed to minimize the problem, a practice that could consume up to 10% of the utility’s treated water demand. In addition, the utility maintained six booster chloramination stations, which used liquid chlorine and ammonia and required daily physical attention.

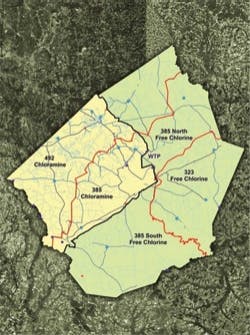

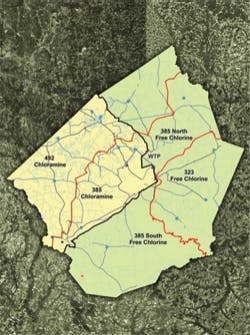

To have the ability to blend the chlorinated purchased water into the existing chloraminated distribution system, the county made the decision to divide its distribution system, with the lower water age area remaining on chloramines and the higher water age portion switching to free chlorine as a residual disinfectant. While it eliminated nitrification and allowed the system to blend with supplemental purchased water sources, the move to using free chlorine presented a number of water quality challenges.

The Johnston County Public Utilities water treatment plant treats water from the Neuse River. This surface water source is high in total organic carbon (TOC), which has the potential to react with free chlorine to form DBPs, such as trihalomethanes and haloacetic acids. Although the plant’s existing process removed a portion of the raw water TOC, chloramination was required to maintain DBP rule compliance.

The utility’s switch to free chlorine as a residual disinfectant would increase DBP formation unless steps were taken to reduce DBP precursors. Several technologies were evaluated, including granular activated carbon (GAC), microfiltration, and a magnetic ion exchange pretreatment process known as the MIEX® process. Following studies by consulting engineer Hazen and Sawyer, the utility chose to install a MIEX system, a selection driven by the performance and lower lifecycle costs of the process as compared to GAC and microfiltration. The new system was commissioned in January 2011.

Pretreatment Results

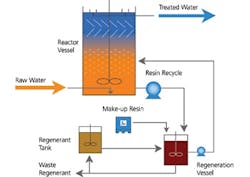

The MIEX process is used as a continuous on-line, ion exchange (IX) process. The magnetic property of the resin enables DOC removal to occur in a fluidized bed, up-flow reactor. The resin beads are much smaller than conventional ion exchange beads, which allows rapid DOC exchange, such that very low resin inventories are required to achieve high DOC removal rates. The process is not affected by suspended solids; hence it is used as the first treatment stage in a water treatment plant. DOC removal at the head of the plant provides significant benefits for downstream processes, resulting in lower coagulant doses being required to achieve water quality goals and, therefore, less chemical sludge production.

The anion exchange process removes negatively charged DOC molecules from the water by exchanging them for chloride or bicarbonate ions that are present on the resin. Humic and fulvic acids, both of which are common DBP precursor compounds, are retained by the resin until being released in a side stream regeneration process. Regenerated resin is then returned to the process for further use. MIEX DOC Resin is highly selective for charged organic compounds and typically removes 40-90% of the raw water DOC. The increased DOC reduction achieved can result in reduced oxidant demand, both for preoxidation applications and downstream disinfection.

At Johnston County, the process is applied as pretreatment to the plant’s conventional coagulation process. Through its application as pretreatment, the system has resulted in an average 64% reduction in the raw water TOC, reducing the chemical demand on downstream processes. Together, IX and coagulation are able to reduce the treated water TOC to 1.5-2.0 mg/L, from raw water concentrations averaging 5-6 mg/L and ranging as high as 10 mg/L. In addition, the plant has reduced downstream chemical consumption by as much as 30%, while improving sludge dewatering ability.

Achieving this low TOC concentration has resulted in treated water quality that meets DBP rule requirements while using free chlorine as a disinfectant. The utility is now able to successfully supplement their water supply with purchased, chlorinated water, while being freed from the challenges of booster chloramination, nitrification, and flushing in areas of their distribution system with the highest water age.

Although there are many potential solutions to DBP rule compliance, the TOC removal achieved in a pretreatment process, such as magnetic ion exchange treatment, allows for increased operational flexibility downstream. This increased flexibility gives utilities, such as Johnston County Public Utilities, the freedom to broaden their options with respect to disinfection chemical selection and application, which allows them to better meet the needs of their customer base.

WW

About the Authors: Barbara Martin is the Western Region Business Development Manager for Orica Watercare. She has a BA in chemistry from Boston University and an MS in geochemistry from Colorado School of Mines. Beth Pyles is the Eastern NA Business Manager/Sr. Water Technologist and has been with Orica Watercare NA for 9 years. She has a master’s degree in chemistry and a Class 4 drinking water license. Pyles also Chairs the Coagulation and Filtration Committee for AWWA.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles