Selecting the Best/Most Efficient Centrifugal Pump Control

By Allan R. Budris

Probably the most important decision a pump user can make, in order to obtain the lowest pump system life cycle cost (Dec 2009 Pump Tips Column), is to select the best pump control method for an application. The best way to make this decision is to conduct a detailed cost/efficiency analysis of the most promising control methods, starting with the pump / system head-capacity curve interactions, followed by the expected operating flow requirements, the initial cost of the drives and associated equipment, and finally calculating the ROI for each of the control methods (or combinations) being considered.

The most common centrifugal pump control methods are

• Stop-Start/Float Level control Operation

• Control Valve Operation

• By-Pass Valve Operation

• Variable Speed Operation

• Hybrid Control (VFD + By-Pass)

• Parallel Operation of Multiple Pumps

• Multiple Speed Motors (2, 3 or 4 Speed)

Stop-Start/Float Level Control Operation

This is probably the most common flow control method used for sewage lift pumps. It can be one of the more efficient control methods, since the pump can operate without any energy wasting pressure break down or by-pass valves. The pump is activated when the wet well level reaches its designated high point, and turned off when the level is pumped down to its designated low point, by means of level sensors. It can be made even more efficient by operating in combination with a variable speed drive and/or multiple pumps in parallel.

There are however, several potential drawbacks to pure Stop-Start / Float Control operation

1. Stop-Start operation can be hard on pump motors, especially larger motors which are limited to a low number of starts per hour. More frequent starts can over-heat the motor and stress the windings.

2. By relying on changes in the intake liquid level (in the wet well) for system flow control, you are also changing the NPSH Available to the pump. This could lead to cavitation damage at low sump levels, which the writer has observed on more than one occasion.

3. Changes in the wet well liquid level also changes the system head-capacity curve, which in turn changes where the pump will be operating on its head-capacity (and efficiency-capacity) curves. The pump will only operate at its highest efficiency at one sump level, and this may not even be the pump best efficiency point (depending on the where the system H-Q curve intersects the pump H-Q curve).

Control Valve Operation

This is generally the lowest cost and most popular method of controlling the flow rate of a pump, but it is seldom the most efficient. Control valves reduce the pump flow rate by increasing the system pressure drop, and therefore forcing the pump to operate further back on its H-Q curve (see figure 1). The pressure drop and energy cost for a control valve can be sizable, especially with high usage, or high specific speed pumps (where the power consumption increases with reduced flow). The writer has even seen applications where, in order to minimize the initial cost, under-sized valves (smaller than the discharge line) were installed for flow control. The result was a relatively high pressure drop, even when the valve was full open.

Discharge Control valves may, however, be the best choose for lower specific speed pumps (with a rising hp-flow curve), on very flat system H-Q curves, where the flow rate does not change that much, and/or when the pump does not operate that often. For such a system, a variable speed drive may be hard to financially justify (over a control valve), even though it might be slightly more efficient.

By-Pass Valve Operation

By-pass valves/lines are often installed on pumps to prevent the pump from operating at very low or zero flow rates, to protect the pump from damage, but seldom for flow control. However, for high specific speed pumps (which starts above a specific speed of about 4,000); on flat H-Q systems; where the flow rate does not change much; and/or where the pump does not operate that often: by-pass flow control may be the best option (see figure 2, and Sept 2009 column). It is more efficient to use by-pass flow rather than a valve in the pump discharge line for system control on high specific speed pumps, when the pump hp-flow curve increases with reduced pump flow rate.

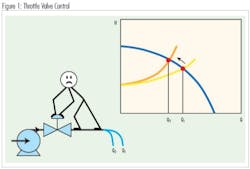

Figure 3 shows the relatively high pressure losses for a discharge control valve on a high specific speed (7,100) water supply pump system. As can be seen, the discharge control valve pressure drop was greater than the suction or discharge line losses (which were each thousands of feet long), and equal to the static head. A needless pressure / energy loss.

Variable Speed Operation

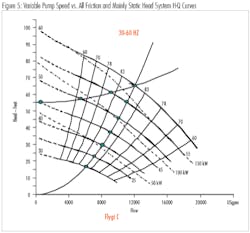

Variable Speed Drives (VSD), and more commonly Variable Frequency Drives (VFD - which can match the motor speed to the load) are usually the most efficient flow and/or pressure control option, especially in systems with high friction losses, large flow variations, and high operating hours (see figure 4). VFDs also eliminate the need for throttle valves and starters.

The biggest reason for applying a VSD is the potential to drastically cut energy costs, which (at the same pump efficiency), are reduced by the third power of the speed reduction. The greater the speed reduction, the greater the energy savings. With an all friction system (see figure 5), the flow reduction follows the speed reduction, and the power drops to 12.5%, for a 50% reduction in speed. On the other hand, with an all static head system, the speed only reduces to 86.5%, for a 50% reduction in flow rate. This would result in a power drop to only 65%, less the reduction in pump efficiency at this reduced flow rate (which could exceed the 35% reduction).

In addition to the large potential energy savings from VFDs, they also offer many other benefits.

• The resulting lower operating speed will increase the life of the pump.

• They eliminate the control valve (and associated losses), starter and any by-pass lines. They are easy to retrofit.

• They generate higher supply side power factors at all loads, unlike a constant speed motor.

• They eliminate the inrush current on start up. Soft starting reduces the stress on the motor, pump, coupling and the supply network.

• They can provide system control logic, fault protection and diagnostics.

Even with all of the above advantages for VFDs, they cannot always be financially justified. In addition to the relatively high initial cost of a VFD, they also have some potential technical issues, as outlined in the writers March 2008 column.

Hybrid Control (VFD + By-Pass)

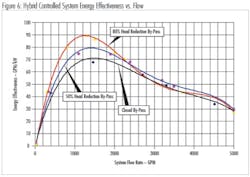

There is a way to further increase the efficiency / energy effectiveness of a VFD controller on a high static head system, during low flow operation, and that is by adding a by-pass control line. This can increase the pump flow rates to higher efficiency values, as spelled out in the writer’s August 2008 column. Figure 6 shows the impact of this control method on energy effectiveness (the number of gallons per minute that can be pumped for each kilowatt of input power) for several by-pass flow rates, on a typical low flow application.

In should be noted that the amount of improvement in Energy Effectiveness from Hybrid Control is a function of pump specific speed. The higher the specific speed the greater will be the savings, since higher specific speed pumps have steeper head-capacity curves, and horsepower curves that are flat or can even decrease with increasing flow rates.

Parallel Operation of Multiple Pumps

A common control method used for applications with large fluctuations in flow demand is to operate two or more (valve controlled) pumps in parallel, where these pumps take suction from a common manifold and discharge into a common header (see November 2008 column). Pumps are operated in parallel as a means of flow control and for emergency back-up (installed spare). However, if the pumps are not properly selected for parallel operation, or operated in the most optimum combinations, pump reliability and overall system energy efficiency can be compromised. Pump selection for parallel pump installations is key to minimizing energy costs.

Parallel operation can prevent pumps from being forced to operate at very low flow / efficiency rates during periods of low system demand, while still having the capability of handling much greater system requirements, by activating additional pumps to match the higher demand. Typically, the best overall efficiency is obtained by operating the minimum number of pumps for the specific system demand conditions. It might even be desirable to have one much smaller pump for every day duty, and a much larger pump to handle the seldom encountered maximum conditions.

Multiple pumps can also be combined with VFD controllers and/or float level control to further improve efficiency or operation, if it can be justified.

Multiple Speed Motors (2, 3 or 4 Speed)

Multiple speed motors can provide some of the same VFD energy saving benefits at a lower cost, for low horsepower applications with several distinct flow requirements. The writer has, however, never seen this type of flow control in an industrial / municipal environment.

Conclusion

With all of the flow control options available, the best way to select the method that will yield the lowest life cycle cost, is to conduct a detailed cost / efficiency / ROI analysis of several of the most promising control methods, assisted by the general guidance presented above.

WW

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles