The operators at the Beaver Dam, WI, wastewater treatment plant knew there had to be a better way to meet their 1.0 mg/L total phosphorus limit. They struggled to feed enough ferric chloride to handle the incoming phosphorus spikes without overfeeding, which would increase sludge production and waste chemical.

To automate the process, staff acquired a new RTC101 Chemical Phosphorus Optimization Solution from Hach. The new system automatically feeds the exact amount of precipitant needed to maintain a programmed orthophosphate set point. By measuring effluent flow and orthophosphate in real time, the controller uses preprogrammed algorithms to automatically adjust the ferric chloride dose ahead of the clarifiers as the phosphorus load changes. If a real time measurement signal is lost, the controller will switch to previously entered data until the signal is restored.

At Beaver Dam, the installation was simple. The orthophosphate analyzer measures plant effluent every five minutes and sends that measurement to the real time controller (RTC) installed in a PLC cabinet along with the measured effluent flow readings. The system then outputs the ferric dosing signal through the PLC to control the chemical feed pumps based upon the set point programmed into the controller.

The system was installed, configured, and operational in less than 48 hours. The lab's test results correlate almost perfectly to the RTC101's phosphorus readings.

Even with substantial pretreatment, influent phosphorus spikes are common at Beaver Dam due to industrial discharges and other unforeseen events. When the system senses the load of phosphorus changing, it increases the ferric chloride dose to maintain the 0.60 mg/L orthophosphate set point.

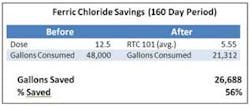

Previously, the staff maintained an average ferric chloride dose of 12.5 gallons per hour. After the installation, the average feed is 5.55 gallons per hour—savings of 56% in ferric chloride costs alone. At this rate, the savings will have paid for the system in less than 12 months.

Moreover, although not yet quantified, the staff believes that an associated decrease in sludge production provides additional savings stemming from reduced solids handling costs.

Hach is an exhibitor at the WEFTEC.12 event and can be found at Booth No. 5739