A Matter of Taste: UF/RO System Features Ozone Pretreatment

BY ANGELA YEUNG

Poor tasting artesian well water that caused rust and corrosion to plumbing fixtures and home appliances was normal in Emmons County, ND, a rural farming community southeast of Bismarck. The South Central Regional Water District utility knew that water from these wells contained high levels of dissolved solids, hardness, and sulfates, as well as arsenic content beyond the safety standards established by the Environmental Protection Agency (EPA).

Those problems are over now, thanks to funding from the American Reinvestment & Recovery Act for an innovative system that combines ozone pretreatment, ultrafiltration (UF) and reverse osmosis (RO) to treat nearby Missouri River water - reducing tap water hardness from 40 grains to as low as six grains. In operation since May 2012, the new Emmons County Water Treatment Plant demonstrates the successful use of ozone as a primary disinfection and pretreatment for the downstream UF and RO membrane technologies with no compatibility issues.

Communities are treating surface water with ozone because it is economical and effective, and the only byproducts are oxygen and water. The challenge – ozone is harsher than other water treatment chemicals, creating a harsh inlet stream for further treatments, such as UF and RO. The tasty water provided by the new Emmons County water treatment plant validates the unique technology of ozone pretreatment for UF and RO membranes with stable operating performance of the membrane filtration plant and the excellent chemical compatibility of the UF and RO systems.

TREATMENT PROCESS

"There are many towns, cities and counties across the U.S. facing water quality challenges similar to Emmons County," said Scott Sedey, Project Manager, H2O Innovation, custom-designers of the new plant. "Finding an economic solution that is reliable and effective is a top priority. The safety and reliability of UF and RO filtration answers their performance needs and is within financial reach."

The new water treatment plant draws raw water from the Missouri river. Ozone is the primary disinfectant for removal of organics. Ozone-oxidized water enters sedimentation basins with coagulant dosage, and it settles for 30 minutes before passing through screen filters to the ultrafiltration systems for pathogen and solids removal down to the 0.03 micron level. The ultrafiltered water then enters the RO system to remove tastes and odors, followed by chloramines dosing prior to distribution. The RO system provides a ratio of 60% permeate to 40% UF filtrate to meet the hardness target of six grains per gallon. The Emmons plant regenerates the ozone on site and has no by-products except oxygen and water, making it safe and trouble-free for local residents.

UF SYSTEM

H2O Innovation selected the DOW™ Ultrafiltration SFD-2860 membrane due to its ozone-resistant PVDF chemistry and its balance of other properties, especially the fiber integrity. Its technically advanced Hydrophilic-PVDF hollow fibers with uniform pore size maintain high performance under a wide range of feed water conditions. The flow configuration is outside-in, which allows for less plugging, higher solids loading, higher flow area and easier cleaning. The module operates in dead-end mode to maximize the filtrate recovery.

EPA regulations require the UF system to undergo a daily direct integrity test to demonstrate a resolution of 3 microns or less. The Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) requires a minimum of 17 psi testing pressure to detect a 3 micron breach. The Emmons plant uses 20 psi as their set testing pressure. The UF system demonstrates 100% integrity throughout the entire operation.

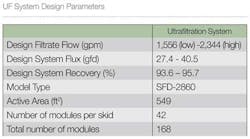

The UF system is designed to operate up to 2,344 gpm of flow during high demand season. Backwash interval, backwash operations, chemically enhanced backwash (CEB) frequency, and clean-in-place (CIP) practices are among the important parameters to be adjusted for UF system optimization. Initial design parameters of the Emmons UF system and operating process parameters are listed in Tables 1 and 2.

Initial design of the UF system included a daily CEB procedure to remove fouling accumulated on the surface of the hollow-fibers for a more effective filtration and a lower pressure drop over operation. However, the Emmons water treatment plant has a discharge limit that does not permit a daily CEB. Instead, a semi-automated "miniCIP" is performed every week. Nevertheless, no chemical cleaning has been performed since startup because the UF and RO cleaning systems were still being optimized.

Despite these challenges, the UF and RO systems have performed well without any glitches, demonstrating great membrane robustness without any cleaning.

RO SYSTEM

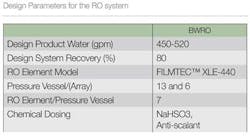

H2O Innovation chose the Dow™ Filmtec™ XLE-440 RO membrane for taste and odor removal because it is a low-energy, high-productivity brackish water RO element that offers the lowest pressure drop in Dow’s portfolio. For the permeate flow of 450 gpm during low demand and up to 520 gpm for high demand operation, a total of 133 elements are used in the format of 13:7 array for stage 1 and 6:7 array for stage 2.

PERFORMANCE TO DATE

After five months of operation, the UF and RO systems have demonstrated steady, sustainable operation and performance with no chemical cleaning.

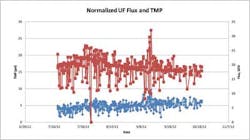

Figure 1 shows the UF system operation, including flux and transmembrane pressure (TMP), with data normalized with temperature. Flux has been at a steady rate of 23 gfd, and TMP has also been a steady line. As the water and surrounding temperature gets colder, dropping down to 50°F, the TMP has been increasing gradually from the initial 3 psi to 6 psi.

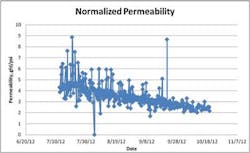

Permeability of the UF system is also dependent on temperature. The normalized permeability data for the UF system demonstrates sustainable operation, as seen in Figure 2. Permeability has maintained around 4-5 gfd/psi in the warmer months, and is slowly decreasing to around 2.5 gfd/psi at around 50°F.

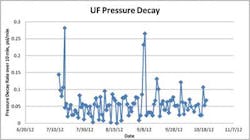

The Dow UF system has passed the required LT2ESWTR integrity test with no broken fiber detected. In Figure 3, a few outliers are shown with higher pressure than the initial set point, possibly due to inaccurate valve opening and closing. Most of the UF integrity test data points lay within the range of 0.05 psi/min to 0.15 psi/min. The UF system demonstrates much tighter pressure decay than the required 0.20 psi/min for fiber integrity.

The Dow UF system guarantees an SDI of <2.5 or less and turbidity of <0.1 NTU, making it ideal for RO pretreatment. The RO system usually requires an SDI <3 as its feed water quality. The RO system has a steady flow of 450 gpm permeate with feed pressure of 100 psi. The permeate conductivity is also very stable at around 13-15 µS/cm.

CONCLUSION

The Emmons County Water Treatment Plant not only provides clean and tasty water to the community, it also demonstrates the successful use of ozone pretreatment for downstream UF and RO systems, which have not required daily CEB or CIP maintenance. The UF membrane has demonstrated good fiber durability and passed all integrity tests, with pressure decay results well below the standard limit of 0.2 psi/min. The residual ozone dosage shows no compatibility issues on the UF membrane, and RO performance is stable with minimal pressure drop.

"We are extremely gratified to report," said Doug Neibauer, Executive Director of South Central Regional Water District, "that after five months, by all measures - permeability, pressure and fiber integrity - the Dow Ultrafiltration filters are maintaining their integrity and drinking water values are holding steady, even under these unusually tough conditions."

About the Author: Angela Yeung is a Lead Technical Service Representative at Dow Water & Process Solutions.