By Richard J. Pope, PE, BCEE

The 53-acre Newtown Creek Wastewater Treatment Plant (Newtown Creek), New York City's largest wastewater treatment plant, is one of Brooklyn's most intimate neighbors, with no buffer zone between residents and the facility. Because the aging plant was unable to meet federal and state effluent wastewater discharge standards, the DEP embarked on a complete facility upgrade - a project that would take more than 10 years to complete.

From the outset, a community in the Greenpoint section of Brooklyn was concerned about the possibility of nuisance odors during construction and beyond, as well as noise, vibration, traffic, and parking. Recognizing the need to work closely with this community during construction, the DEP resolved to address six fundamental questions related to nuisance odor issues:

- What are our odor criteria and goals?

- Where are the odors?

- How strong are they?

- Can they be detected off site?

- Can they be controlled?

- How does the plant become a better neighbor?

Odor Criteria and Goals

Within New York City, two criteria are used to assess odor impacts: the city's Environmental Quality Review (CEQR) Technical Manual odor threshold of 1 ppb for hydrogen sulfide (H2S) from the project at sensitive receptors, and the New York State Ambient Air Quality Standard (NYSAAQS) of 10 ppb H2S in ambient air. A sensitive receptor is defined as a residence, school, church, or park located in the community immediately adjacent to a source facility like Newtown Creek. Implicit in the use of the 1 ppb of H2S as the significant odor threshold is that any control measures needed to achieve this level will simultaneously address other residual odors common to wastewater treatment plant (WWTP) operations, such as ammonia, amines, organic sulfides, mercaptans, indole, skatole, and aldehydes. Since the 1-ppb standard is extremely low - and at the lowest end of the detection range of currently available monitoring technology - an air dispersion model is used to demonstrate compliance with this criterion.

The NYSAAQS's one-hour average requirement of 10 part-per-billion by volume in air (ppbv) for H2S - applicable for all locations beyond the facility's fence line - is designed to protect the quality of life for the surrounding community. For the Newtown Creek upgrade, the maximum off-site one-hour average H2S levels were to be determined at sensitive receptor locations to compare with the city's 1 ppbv threshold, as well as any receptor location beyond the fence line to compare with the NYSAAQS of 10 ppbv.

Odor Parameters

Odors associated with WWTPs reflect various factors, including the nature of the raw influent wastewater; diurnal variability in the influent flow and/or odor load; type of unit operations employed at the plant and how it is operated; and occurrence of upset conditions. In addition, physical conditions within the plant, such as turbulence caused by aerating wastewater, weir drops, changes in the direction of flow, hydraulic jumps, drop structures, pumping, and other factors, can increase the potential of odorous compounds being volatilized or stripped from solution and emitted to the ambient air.

Many odor-causing compounds associated with wastewater facilities are sulfur-based compounds, such as H2S and mercaptans, with H2S being the most prevalent malodorous gas attributed to domestic wastewater collection and treatment. Since the conditions leading to H2S formation usually favor the production of other odorous gases, such as ammonia and mercaptans, which may have higher detectable odor thresholds, H2S is commonly used as a trace odor indicator of their presence.

Where are the Odors, and How Strong are They?

To determine which unit operations at Newtown Creek emitted odors, a series of five separate comprehensive odor surveys were performed during the months of June, July, August, September, and November of 1997. Hydrogen sulfide production is known to be at a maximum when wastewater temperatures are high (as in summer months), since high temperatures cause the liquid's oxygen content to decrease and biological activity to increase. The surveys were performed over a three-to-four-day period, with samples collected at various times of day, corresponding to varying flow rates because of typical diurnal variations in flow.

Can Odors be Detected Off-Site?

Odor dispersion models are the best tools available for evaluating off-site impacts of odor emissions from plant operations, and the regulatory approved model used for Newtown Creek had a receptor grid that extended 2 ½ miles from the plant fence line in addition to 245 sensitive receptors. The model was run to predict the one-hour average H2S level at every sensitive and discreet sample location. Additionally, it was run at every intersecting line node of the receptor grid for every hour of the five years based on the meteorological data from the input H2S emission rate at each plant odor source individually and collectively.

The results of the initial odor dispersion model identified multiple odor control locations at the plant, and they were divided into five independent complexes. The odor dispersion model was also executed to determine the control required at each complex and the height of the exhaust stack.

How Can They be Controlled?

Various odor control technologies were considered for each of the different unit operations identified by odor dispersion modeling: wet scrubbing, biofilters, biotrickling filters, aeration tank diffusion, and activated carbon. Based on the on-site investigation results, source concentrations of H2S were relatively low, with average levels generally 1 ppmv or less. In addition to the low levels of H2S, the amount of available space for the five regionalized odor control areas (where a total of 645,000 cubic feet of odorous air was to be treated) was very limited. This favored odor control technologies with smaller footprints.

Activated carbon was ultimately selected because of the low levels of influent H2S, its ability to manage the exhaust stack discharge level of 25 ppbv, space limitations at the plant site, and the city's desire to "keep it simple" for its operators. In choosing activated carbon, the DEP would meet the 25 ppbv exhaust stack requirement, and inclusion of stand-by carbon vessels would satisfy redundancy issues requested by the community.

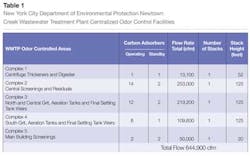

Five regionalized/centralized locations were selected at Newtown Creek to position the total of 43 dual bed activated carbon vessels - 35 for standard operations and eight for standby (see Table 1). The number of exhaust stacks and heights for each of the five centralized odor stations were determined by odor dispersion modeling to maintain compliance with city and state H2S requirements. Exhaust stack design also had to take into account the discharge of volatile organic compounds (VOCs) and comply with New York State regulations (Air Guide 1) relating to short-term (one-hour) and annual guideline concentrations.

How to Become a Better Neighbor?

When the Greenpoint community first heard Newtown Creek was upgrading its facilities to meet regulatory requirements, residents banded together and, with DEP support, formed the Newtown Creek Monitoring Committee (NCMC), whose mission was to monitor DEP's progress with the upgrade design, construction and plan operations.

As part of this agreement, the DEP funded a community liaison and an independent consulting engineer to assist the NCMC. The engineer's role was to advise the NCMC on an ongoing basis throughout the design and construction period and for a reasonable time thereafter on issues related to operations. The NCMC used these resources to insist that nuisance odors be kept under control and bring pressure to bear when nuisance odor conditions began to slip.

The NCMC also worked with the city to propose a nature walk along Newtown Creek and Whale Creek Canal that fit neatly into the city's Comprehensive Waterfront Plan, promising to provide public access to and along New York City's coastal waters. This action, together with the installation of the Visitor's Center, provided the community with a recreational oasis among the industrial setting of the plant.

Conclusion

Answers to the six fundamental questions did not come quickly or easily. Planning, testing, modeling, designing, installing, and operating systems to regulate odors throughout the upgrade was a struggle and amounted to nearly 10 percent of overall project costs. Nevertheless, as the final odor control systems are being permitted and the plant upgrade is reaching its conclusion, the city can point with pride to the results of its efforts: the odor control systems have achieved compliance with city and state H2S requirements; community- monitored odors and odor complaints have been reduced; and the city and plant have worked hard to remain good neighbors.

About the Author: Richard J. Pope, PE, BCEE, is an environmental engineer who for the last 31 years has focused on providing air and odor services for municipalities and industries. A vice president at ARCADIS, he directs a team of odor specialists providing comprehensive odor services. Pope has conducted over 250 odor-related projects at wastewater facilities, landfills, and composting and industrial facilities in cities nationwide and around the globe.