Flow Meter Solves Tough Application Challenge for City of Cedar Rapids

By Nick Voss

Overview

The City of Cedar Rapids, Iowa, Water Division treats and distributes groundwater from alluvial wells. (see Fig. 1). The Water Division has over 50,000 metered accounts, including residential, commercial and industrial, and serves a population base of around 128,000 people.

Plant operations and instrument technicians determined in 2011 that they needed to replace under-performing flow meters in two booster stations as well as in their water intake system. Their existing flow meters were strap-on ultrasonic transit-time meters and they were susceptible to electrical and radio frequency interference from electrical equipment in the station, such as the pumps' variable frequency drives.

The Problem

The City of Cedar Rapids water distribution system includes two booster stations: The J Avenue NE Booster Station has eight vertical turbine pumps; the Bowling Booster Station SW operates with three horizontal split case centrifugal pumps. Measuring flow in booster stations such as those found in the City of Cedar Rapids is both important and difficult. Accurate flow measurement at booster stations can impact both the supply and delivery of water. Challenges can include managing multiple pumps and a variety of line sizes, dealing with interference issues and retrofitting existing piping configurations.

For the City of Cedar Rapids, the clamp-on ultrasonic flow meters in service at the two booster stations were not only underperforming and susceptible to electrical and radio frequency interference, they were also maintenance intensive. Their ultrasonic transducers required frequent cleaning and re-greasing to maintain measurement accuracy at an acceptable level.

When the city's water division team began the process of selecting a new type of meter, they knew water quality also played a role in their decision-making. The plant technicians were aware that condensation and exterior pipe wall rust could contribute to transducer maintenance if they opted for new ultrasonic flow meters.

In addition, the team was constrained by an application with little straight-run pipe and an irregular flow profile. Many flow meter sensing technologies require multiple lengths of straight pipe to produce a stable flow profile in order to provide accurate measurement. Full bore meters also were not a feasible option due to space limitations.

The Solution

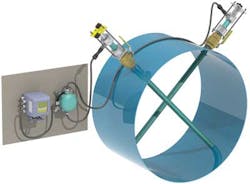

The City of Cedar Rapids Water Division contacted the applications team at McCrometer for analysis of its flow measurement needs. The company's applications team reviewed the situation in Cedar Rapids and recommended the FPI-X Mag™ flow meter with dual sensor assemblies (see Fig. 2).

The FPI-X product configuration is the newest line extension of the company's FPI Mag® product line. It is specially designed to accurately measure flow from multiple pumps in series.

Analysis under simulated flow conditions at McCrometer's Flow Lab determined that the meter's dual sensor assembly provided the best solution to handle the challenging flow variances at the booster stations. In addition, the meter's insertion-style design allowed for easy installation within the city's tight space requirements.

The meter's design features two insertion-style multi-point sensor assemblies oriented at 90 degrees from each other in an "X" configuration. The advantage of the dual sensor "X" configuration is that it averages over the complete 2-dimensional cross-section of the pipe, resulting in the meter being less sensitive to major upstream flow disturbances such as the swirling and turbulent flow generated by pumps.

The FPI-X Mag meter also stood out to the city's team because of its economical product cost, low total installation cost, low overall cost of ownership and high accuracy. Its multi-point electromagnetic flow sensing design provides accurate measurement under turbulent flow conditions and high repeatability in the city's demanding water quality environments.

Further, the flow meters provide operational information through a supervisory control and data acquisition (SCADA) system so plant staff can maintain suitable flow rates to fill water storage towers and maintain totalized flow records from each station. The flow meters also provide up-to-date information on the condition of the distribution system in the affected pressure districts.

Cedar Rapids' new units have been operational for over 24 months at both of the city's booster station sites. One FPI-X Mag meter was installed on the single 30-inch line at the SW Bowling Booster Station to accurately measure the flow from its three centrifugal pumps (see Fig. 3). Two FPI-X Mag meters were needed at the NE J Avenue Booster Station, each measuring the total output of four vertical turbine pumps on two 24-inch lines (see Fig. 4). After more than two years of analysis, the Water Division operations and maintenance team reports that the new flow meters have greatly improved accuracy and nearly eliminated maintenance problems experienced with strap-on ultrasonic flow meters at its booster stations. "The FPI-X Mag is between maintenance free and maintenance friendly," said Bill Connolly, an Instrument Technician with the City of Cedar Rapids. "We don't get any of the interference that occurs with ultrasonic models. [It] is easy to set up and very accurate."

About the Author: Nick Voss is a Product Manager for McCrometer, a leading global flow instrumentation specialist specializing in the design, manufacture and testing of flow metering solutions.