Advanced Grit Management: A Rigorous Philosophy for Grit Removal

By Marcia Sherony

Screening of raw incoming water and grit removal at the headworks provides vital primary protection for all downstream treatment and equipment in a wastewater plant. Yet all too often, headworks protection is undervalued or misunderstood.

Conventional design for headworks grit removal equipment at wastewater treatment plants (WWTP) is focused on a misleading standard assumption that the majority of grit particles are spheres of silica sand greater than 212 microns in diameter with a specific gravity (SG) of 2.65. This is a false premise, as these assumptions rarely apply to wastewater. Systems designed around this 'ideal' target grit particle typically only remove 30 to 50 percent of incoming grit.

Additionally, the trend for more advanced biological wastewater treatment processes aims to provide better effluent quality in a smaller footprint. However, the small footprint makes them vulnerable to grit accumulation. While biological processes need better grit protection to be efficient and effective, providing more space for primary screening with finer screens and the need for more frequent cleaning and grit disposal could negate the objectives of saving space and leaner operations.

Without proper protection at the headworks, grit that is not captured will pass directly to the biological processes, where accumulation affects their performance.

The Harmful Effects of Grit

The effects of unremoved grit on a plant can include:

- Abrasive damage to mechanical equipment, such as pumps and valves, often leading to failure

- Damage to sensitive filters and membranes

- Deposition of grit and sediments, reducing flow and tank volumes, and requiring physical removal and plant downtime

- Disruption of biological processes

- Loss of efficiency in aeration tanks, resulting in significant energy waste

- Heavy load on maintenance budgets and staff

Before grit within incoming raw waters impacts expensive and sensitive treatment processes, providing more effective protection at the headworks lies at the heart of the Advanced Grit Management™ (AGM) approach.

What is Advanced Grit Management?

Collaboration between experienced plant operators, consulting and design engineers, as well as important academic research centers have pinpointed some of the most important factors and led to a range of AGM solutions. The term refers to an approach to grit removal whereby systems are designed to achieve 95 percent or more removal efficiency while targeting grit particles of 75 to 150 microns. Grit removal systems that have been based on AGM typically remove 85 to 95 percent of the total amount of grit entering the plant.

Slow to be adopted initially, the underlying scientific principles have gradually become accepted. Installation of AGM techniques is accelerating with close to 500 installations based on this approach operating in North America.

The Essential Starting Point

The first premise of AGM is that incoming grit has a wide variability in particle size, shape and SG - each impacting the all-important settling velocity. This modifies the concept of an 'ideal,' or uniform, grit size by utilizing more realistic assumptions and is based on extensive sampling and observation at a wide range of plants across North America. The distribution of these particle variables in the incoming load at different plants serving different areas and in different seasons has major implications for the effectiveness of removal.

For example, as much as 70 percent or more of the grit load can be smaller than the standard 212 microns diameter presumed by conventional design. Conventional removal would, therefore, miss most of it. This reality means that profiling the incoming grit at a specific plant, and designing the grit removal system for fine particle removal while considering the settling velocity, can give a true measure of expected removal efficiency.

Settling, Size and Specific Gravity

Recent industry research projects have compared wastewater grit and clean sand settling characteristics. Combined with experience in the field, the findings indicated that actual grit particle settling velocities are significantly less than physical size alone would indicate. For example, municipal grit settles more slowly than would be conventionally expected based on its physical size, providing strong evidence that simple physical particle size analysis is not sufficient to accurately characterize municipal grit.

The importance of this lies in the fact that settlement time is a basic process design parameter, and if settlement is slower than predicted, more particles will be left in suspension to cause problems downstream.

Grit Particle Settling Velocity

Grit particle size in isolation has previously been assumed as the major criteria used for system design. However, characteristics such as shape and SG can significantly affect grit particle settling velocity. Acknowledging this influence on settling velocity and allowing for it in system design is critical for achieving desired results.

For example, the differences in shape can be seen when the same-size grit and clean sand are viewed through digital imaging particle analysis (see Fig. 1). Even clean sand is seldom spherical in real life, while grit edges are even less defined and affect settling velocity more.

Grit acts differently than clean sand, and understanding its behavior requires knowledge of how it behaves in a WWTP. It is not uncommon for large grit particles (300 micron and larger) to settle as though they are a much smaller particle if their shape, size and SG affect the settlement rate.

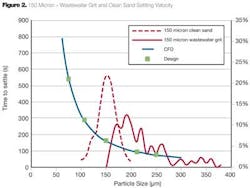

There have been no standardized methods to sample or characterize grit, but a better understanding of its behavior can be gained in a laboratory using a variety of measuring and observational techniques (see Fig. 2).

An example of differences found in settling velocity between sand and actual wastewater grit particles at comparable sizes.

Guaranteed Results and Savings

Computer modeling using Computational Fluid Dynamics techniques is invaluable in simulating particle behavior in laboratory analysis. Third-party field testing and collaboration with industry experts and academic institutions have also contributed to developing AGM as a robust approach.

Using these disciplines leads to grit control systems with superior performance, maximized design flexibility and minimal maintenance requirements to serve the complex needs of WWTPs. Indeed, such has been the recent development of AGM techniques that specific high levels of grit removal can now be routinely guaranteed.

One type of plant rarely fits all. Hard-earned knowledge of grit characteristics and best practices gives AGM practitioners a matrix of unit processes and a wide range of tools capable of matching and solving site-specific requirements. Pilot testing offers further opportunities to refine the treatment approach.

Although a custom-designed grit removal plant may be seen as a little more expensive, the additional high ongoing costs of grit damage, grit removal and related plant inefficiency can easily outweigh any perceived savings gained in opting for standard systems such as simple, mechanically-induced vortex grit control units.

Growth and Acceptance of AGM

Technological developments within the wastewater industry have been commercialized over the last 20 years that allow plants to achieve removal efficiencies of 85 to 95 percent. While slow to be accepted early on, these technologies are seeing tremendous growth and can effectively protect downstream processes in a small footprint with flexible operating parameters and guaranteed results. Cost-effective, while being designed to fit the needs of plants in virtually any range of flows, such systems are rapidly becoming the norm in modern WWTP design.

About the Author: Marcia Sherony is national sales manager for Hydro International's Wastewater Division.

Web-based Resources

A central web resource exploring AGM has been established by Hydro International to provide a reference point for research and technological development. The website, www.AdvancedGritManagement.com, provides a full exploration of the approach, alongside a compilation of industry research and technical papers presented at WEFTEC, regional water conferences and industry events, as well as publications throughout North America. The website also contains advice on system design and the considerations involved. For further information, email [email protected], visit www.advancedgritmanagement.com or www.hydro-int.com, or call (503) 615 8130.