By Robert Gerena, Sean Bui, Gil Hesia and Greg Webster

The city of Hayward, Calif., is known as the “Heart of the Bay” because of its central location in the San Francisco Bay Area, as well as its caring environment. Hayward’s primary water source is the San Francisco Public Utilities Commission’s (SFPUC) water delivery system, particularly the Hetch Hetchy Reservoir, which delivers water via a gravity-fed system from the Sierra Nevada mountain range near Yosemite National Park about 120 miles away.

With multiple pump stations, the staff at Hayward’s Utilities & Environmental Services Department began looking for a new flow meter to replace a non-operational one with a goal to improve the pump system’s efficiency by allowing for accurate tracking on how much pumped water was needed each day from its reservoir.

The Problem

The Hetch Hetchy Dam and Reservoir began supplying water to the San Francisco Bay Area in the 1930s. The water flows first to SFPUC facilities, where it is disinfected; it is then sent on to SFPUC’s wholesale customers, including Hayward as well as San Francisco.

The water is delivered to the city’s transmission system through two turnouts, where it is stored in the city’s reservoirs and delivered to consumers via the distribution system. A portion is directed to the Hayward Hills elevated pressure zones through a series of pumping stations that begin at the 250-foot elevation in the city (see Fig. 1).

“We identified the non-operational meter at a pump station that’s located at the 750-foot elevation,” said Sean Bui, a department electrician. That station has a 4.5 million gallon tank (see Fig. 2) and five pumps. “We had a problem there because replacing the flow meter would be a challenge due to its location in an underground vault,” Bui continued. Installing a traditional inline spool-type meter in the cramped vault would have required turning off the water supply, cutting the pipe, installing the new meter, welding the pipe back together, and turning the supply back on, which would require expensive labor and equipment. But installing an insertion mag meter, he said, would give them the necessary accuracy and would fit easily into the tight vault space.

“Accurate water flow measurement at the 750-foot level pump station is important because it enables the city staff to monitor and record water use in that zone, as well as to synchronize pumps when bypass pumping is necessary,” Bui continued. Closely monitoring all of the system’s pumps also helps to ensure efficient operations by keeping pump use and energy-related costs down. Pump efficiency is important because energy costs associated with running the pump stations is one of the department’s biggest system expenses.

Gil Hesia, a department mechanic added, “When you have more than one pump in service, efficiency decreases due to friction losses that occur as you increase the flow through a given size pipe.” It is more cost effective to run fewer pumps, and run them for a longer period of time, than it is to run all five pumps. “For example,” he said, “running the fourth and fifth pumps at the 750-foot pump station combined only adds about 400 gallons per minute (gpm) total to the station flow (where each pump is rated at 650 gpm).”

Hesia explained that it helps to know how much water is being used and at what times of the day the highest use occurs. “We capture that flow data through our supervisory control and data acquisition (SCADA) system to optimize all pump operations to match the seasonal demand,” he said, “and also to optimize time of day use to help ease pressure on an already burdened electrical grid.” This allows the city to take advantage of various programs Pacific Gas & Electric (PG&E) offers for implementing energy saving strategies.

Adjusting to the seasonal demand is necessary to balance supply needs closely while avoiding the storage of the water for extended periods of time. With regard to disinfection residual, water has a finite life and must be consumed before the disinfectant level degrades.

The Solution

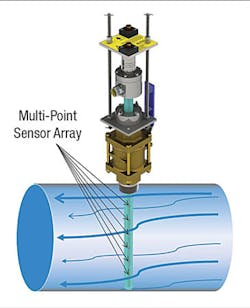

Hayward’s Utilities & Environmental Services Department staff talked to its flow specialist representative at the Frank Olsen Company about its need for a new, highly accurate, insertion-style flow meter. McCrometer’s FPI Mag® Flow Meter was recommended because of its overall suitability for the project’s requirements (see Fig. 3). Manufacturer product support was an important factor in the selection process.

The FPI Mag flow meter is designed to be installed using a simple hot tap process, which makes installation easy in tight spaces (see Fig. 4). The Frank Olsen Company felt confident that recommending the FPI Mag would be the best solution for the city of Hayward’s need to deliver consistent measurement results within the cramped vault space.

The Technology

The FPI Mag meter’s next-generation design helped Hayward achieve its measurement accuracy objective, allowing more efficient pump operations at a lower cost while meeting seasonal water delivery schedule demands and protecting the treated water in its system during California’s drought crisis.

The FPI Mag meter’s signal converter features an advanced filtering algorithm to support its high accuracy of ±0.5% of reading from 1 to 32 ft/s and ±1% from 0.3 to 1 ft/s. Built-in dual 4-20 mA outputs offer communication flexibility. Additional programmable outputs support the city’s SCADA system for continuous monitoring. The meter’s converter features a simplified menu structure, which made it easy for any city staff member to connect the meter to the facility’s monitoring system.

Conclusions

After choosing McCrometer’s insertion configuration FPI Mag meter for this application, Utilities Operations & Maintenance Supervisor Robert Gerena said, “Reports from my electricians indicate that the McCrometer FPI Mag meter’s design is more reliable and easy to program. The installation was quick and easy, and the new meter is performing well and meeting all our requirements.”

At the conclusion of the project, Bui said, “I’m very satisfied with the service from McCrometer and its local sales representative. I would recommend buying this product again in the future.”

About the Authors: Robert Gerena is a supervisor, Sean Bui is an electrician, and Gil Hesia is a maintenance mechanic, all with the city of Hayward, Calif. Greg Webster Sr. is an applications specialist for McCrometer.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles