By Ryan McKeon

Last July, a normal Tuesday afternoon at the University of California in Los Angeles was suddenly disrupted by a major water main break, when a 93-year-old, 30-inch pipeline ruptured on the premises. By the time the flow was stopped, an estimated 20 million gallons of water had roared through the campus, down Sunset Boulevard and into surrounding Westwood, stranding motorists, damaging over 700 cars, creating a massive sink hole, and causing millions of dollars of damage to historic campus structures. What followed was a herculean cleanup effort.

The American Water Works Association estimates that more than 700 water main breaks occur daily in the U.S., and this rupture is believed to have been caused by corrosion and structural problems, issues that commonly plague the nation's aging water infrastructure. In many cases, these structural issues create relatively small leaks that often go undetected, eroding the supporting soils and undermining the pipe installation until a rupture occurs.

Even if the liability risks of collateral damage from a main break are minimal to none, subsequent leaks can decrease revenues and compound existing stresses on clean water sources.

According to the Environmental Protection Agency, U.S. water utilities lose between 6 and 7 billion gallons per day due to leaks -- approximately 16 percent of potable water produced. Similarly, the Congressional Budget Office estimates that for most rural and urban systems, close to 20 percent of all the water they produce is lost to leaks. Regardless of which number is more accurate, it is too high. In truth, the amount of water lost to leaks varies widely and in some older systems, the actual loss may be much higher. What is important is identifying how much water a utility loses and how it can ultimately be prevented.

In an age of severe drought and water scarcity when utilities are encouraging their constituents to conserve, the cost of a comprehensive leak-detection and prioritized remediation program must be evaluated in comparison with the expense to develop new water sources, respond to main break damages, and treat and convey the water product itself. Even in areas of water abundance, it is illogical to treat and distribute water through a system that loses a significant portion due to leaks and that is poised to fail.

So how do you develop a truly effective leak-detection program? How can you maximize the impact while controlling costs and yielding good data for an effective asset management plan?

Not too long ago, leak detection was more art than science. Utilities often awarded contracts to the bidder with the lowest dollar per mile, with little consideration for how thorough or effective the detection methods might be. Proposals rarely provided adequate details on evaluation techniques, including the number of soundings captured per mile, nor did they consider the specific approaches for pipes of varying material, size and pressure. Some areas might have been evaluated effectively, while others may have been hit or miss. Further, there was little if any "proof-of-performance" evidence that leak detection was, in fact, professionally completed.

When leaks were found (and many were not), they were typically noted on paper-system drawings, which another person had to tabulate and prioritize in order to develop remediation recommendations -- it was labor intensive and time consuming. Worse, the data provided was often of limited value in establishing shovel-ready mitigation programs that addressed the exposed leaks. Many utilities invested in leak-detection projects only to find they had little to no impact on reducing real losses.

Today, due to refinements in processes and advances in technology, this has changed, placing leak detection solidly in the realm of science, not art. Not only can a comprehensive leak-detection program find leaks but it can also be an integral part of asset management and provide valuable data for ongoing system maintenance.

Understanding Resolution Needs

The goal of any leak-detection survey is to accurately and economically identify as much leakage as possible. The key is to balance the investment with the potential reward. The primary driver for both (in terms of identified leakage) is the resolution of the leak survey. Similar to a flat-screen television, leak survey resolution is a measure of detail -- the higher the detail (the more data points/sounding samplings), the higher the resolution. Some water systems can effectively be surveyed with low-resolution approaches (such as hydrants only), while other systems require a much higher resolution approach to be effective (such as all hydrants, valves and service curb stops).

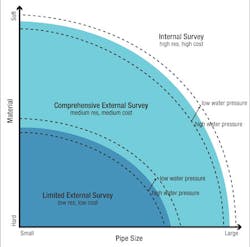

There are three primary environmental factors that drive the resolution required for an effective leak-detection survey (see Fig. 1):

- Pipe material: Softer materials (e.g., plastic) do not transmit sound as effectively as hard materials (e.g., ductile iron).

- Pipe size: Larger diameter pipes have a greater capacity to attenuate (absorb) sound.

- Water pressure: All else being equal, leaks at lower pressures create a less intense noise signature.

Understanding these factors, it is clear that a higher resolution (and higher cost) survey does not necessarily provide more useful information or more value to the utility. Lower resolution survey approaches may be adequate for systems, or sections of systems, that are predominately ductile iron or cast iron pipe. Conversely, systems with a high percentage of PVC mains may require a higher resolution of survey points to pinpoint problem areas.

On large-diameter pipes, particularly nonmetallic pipes with limited exposed contact points, an internal sensor (free-swimming or tethered) may be the only truly effective approach to find leakage. For many utilities, a hybrid approach that matches the resolution to specific materials, diameters and pressures can provide the most useful information with the highest return on investment. This is particularly true if leak detection is coupled with comprehensive data capture that creates transparency and drives accountability.

Where Leak Detection Becomes Asset Management

If all you are receiving from your leak-detection program is the location and perhaps quantification of leaks, then you are leaving a significant opportunity untapped. The mobilization of field staff represents the largest cost component of a leak detection program. So if they are not providing as much data as possible, you are not maximizing your investment.

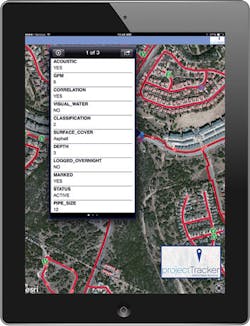

Equipped with geographic information system (GIS) software on a mobile device, field crews can document and transmit data not only on leaks found but also on other system conditions. Crews can help update GIS system mapping by documenting discrepancies between the existing GIS mapping and actual field conditions. This includes documenting the location of discovered assets that weren't on system maps or included in the GIS database.

Perhaps more importantly, crews can determine the "as-is" condition of assets and capture observations, such as meter pits, missing lids or valves that can't be located or accessed. In some instances, meters are found to be altogether removed and replaced with straight-pipe plumbing, which in many cases is poorly installed and leaking, compounding non-revenue losses. Of course, leak details such as precise locations, loss-rate estimates and digital photographs are of paramount interest and need to be thoroughly documented.

Since this data can be captured and posted to a web-accessible database in real-time, it can be immediately available to support smarter decision making across the organization. Detailed leak reports are just a click away and can include priorities established based on the magnitude and location of the leaks, and work orders can be dispatched immediately for urgent conditions. Further, with updated as-is usability information on the valves, utilities can more efficiently develop sequencing protocols for the necessary shutoff operations, limiting the duration and footprint of repair work.

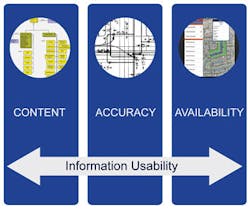

By capturing as-is field conditions on the fly, leak-detection efforts can not only identify water losses but can also add tremendous value to a utility's strategic asset management program by improving the content and accuracy of the organizational knowledgebase.

Built-in Transparency and Accountability

Because data capture is an integral part of every survey point -- not just those where leaks are found -- leak detection with asset data capture is a much more transparent process. The utility gains a clear picture of problem areas and leaks that must be addressed, as well as the peace of mind that comes from knowing which areas are in good shape and where maintenance can be deferred. There is no guesswork about whether an area was evaluated: time- and geo-stamped data is available as undeniable proof of service.

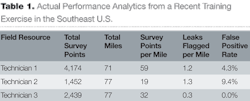

A reliable leak-detection and asset-inventory program will include built-in performance monitoring and quality control components to confirm the credibility of the data being introduced. When each survey point is being documented, performance analytics such as Survey Points per Mile and False Positive Ratios can be computed and evaluated to aid in project oversight. In addition, a certain percentage of survey points should be reevaluated to measure the False Negative Ratio (see Table 1).

Experience is Important

The Pagosa Area Water and Sanitation District (PAWSD), located in southwest Colorado, had a significant leakage issue. In 2013, leaky pipes accounted for losses totaling approximately 33 percent of its water production -- over twice the national average. PAWSD had to find an effective solution to identify its real losses. The District had tried several different approaches to leak detection, including site excavation, pressure testing and helium injections, all with no success. Due to a variety of unique distribution system characteristics, including elevation changes, rocky terrain, depth of bury for freeze protection, and use of PVC pipe, leaks in its system are harder to detect.

Wachs Water Services (WWS) was initially contracted to evaluate 95 miles of pipeline, divided into several sample sections in various parts of the city. The company quickly found three leaks (21 total were detected in the assigned sections), prompting PAWSD to extend the contract by another 205 miles. WWS helped the board of directors understand this process and the challenges of leak detection by allowing them to listen to lines with and without leaks to demonstrate the differences.

In addition to finding leaks and addressing losses and lost revenues, PAWSD gained a more complete picture of its system. Of the 7,300 sounding survey point records documented, 255 yielded a mapping discrepancy (mostly with features missing in GIS), and over 500 captured asset defects (features in GIS that couldn't be field-located.) This valuable asset management data will support more efficient operations, streamline maintenance efforts, and lend support and credibility to capital improvement programs.

From Detection to Management

Leak detection is a necessary step to reduce losses and prevent water main breaks. The benefits of leak detection are obvious in increased revenues, lower risk from contamination, lower liability due to a reduction of main breaks, and increased public trust.

A well-developed leak-detection program that also includes asset data capture and integration can provide much more ongoing value. By providing sound, accurate and verified data on asset conditions and accessibility, the data captured can update and correct a utility's GIS system and support foundational asset management objectives.

Leak detection can be cost effective as well by providing real-time, transparent and immediate data that can be used for developing shovel-ready repair plans. With proper data capture, utilities can gain assistance in prioritizing system work, acquiring critical information for valve sequencing, expediting repairs and maintenance, and issuing and tracking work orders more efficiently.

In an age when every drop of water -- and every dollar -- counts, a utility simply can't afford not to take advantage of the added value provided by new mobile GIS technologies. By integrating comprehensive data capture into the leak-detection workflow, a leak-detection program can serve as a very effective gateway to full asset management.

About the Author: Ryan McKeon is vice president of Strategy & Technology for Wachs Water Services. Bridging the gap between theory and practice, McKeon leverages his understanding of geospatial technologies and water distribution systems to develop practical water operations-focused solutions. He is a frequent speaker at industry events focusing on the need for the GIS community to provide accurate and useable geospatial solutions to significantly reduce the consequences of the ever-increasing failures of our aging water systems.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles