By John Stevenson

The Aqua America water treatment plant in the town of Tiffin, Ohio, was built in the 1920s and is situated on the Sandusky River. The plant processes 3.4 million gallons per day and was facing challenges of producing high-quality drinking water.

A full measure of seasonal variety, combined with the runoff from a thriving agricultural environment, caused the small-town water facility to continually encounter adverse conditions. In a short time period, influent turbidity could fluctuate from 10 to 2,000 NTU. This "flashy" water source posed frequent operational difficulties and made it very difficult for the plant to meet increasingly stringent regulations.

In an effort to remain compliant, Aqua America enhanced coagulation, but this increased the sedimentation rates and exacerbated sludge blanket depths. Because of this, the winter months often proved to be extremely problematic; given the icy conditions and the inability to remove the tank from service, the plant experienced short-circuiting.

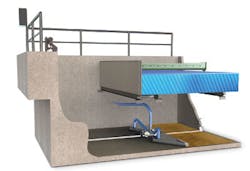

As a result of these ongoing problems and frequent halting of water production, Aqua America sought a solution to eliminate the tedious, time-consuming removal of the tanks for cleaning and improve upon the lost revenue. The utility needed a cost-effective, automatic solids removal solution and opted to install Brentwood's cable-driven SedVac sediment dredge system in 2010.

Once installed, the system produced positive results for the Tiffin plant. It now consistently removes sludge with 3-percent solids concentration and reliably handles heavy loads without stoppage, despite peaks in raw water quality of 2,000 NTU. By running SedVac once per day, even during peak solids loading, Aqua America is able to maintain a clean floor.

A Non-Traditional Approach

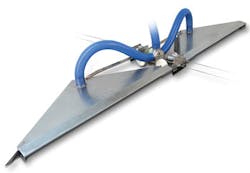

SedVac's non-traditional design allows it to operate more effectively than clog-prone vacuum systems by scraping the floor and removing the compressed solids at the floor level. It does this by utilizing triangular header wings with 4-inch-high intakes, as opposed to the commonly used pipe headers with orifices. SedVac also features a strong chassis -- the crux of the system -- which makes it capable of withstanding the pulling power of the winch system and the harsh elements of submerged environments.

The installation of the system required minimal modification to the basin, making the retrofit very cost-effective. Within just one year, SedVac was able to generate a positive return on investment for Aqua America. The basins now require cleaning only twice per year, as compared to the cleanings that had previously been required once every three weeks. For this small facility, those savings compute to approximately $65,000 per year.

Testing the System

Impressed with the results that the Brentwood SedVac system was able to produce, Aqua America agreed to participate in a study of the system's performance and capabilities.

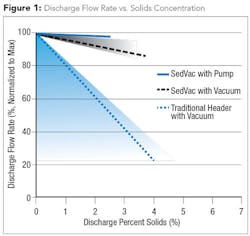

As shown in Figure 1, despite the increase in solids loading, both the pump and vacuum configurations of the SedVac unit had low variation in the discharge flow rate. The study demonstrates that SedVac maintains consistent discharge flow rates through a wide range of solids loadings -- a key factor in preventing system clogging.

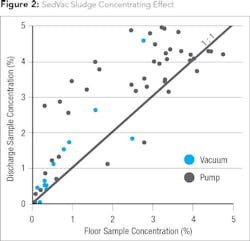

Two full-scale SedVac pilot tests were also performed, comparing settled solids collected at point locations on the tank floor to corresponding discharge composite samples. In both vacuum and pump configurations, Figure 2 shows that SedVac removed settled solids at concentrations greater than the intake on the basin floor. The study suggests that the shape of the header wing funnels solids toward the pump or vacuum intake, concentrating the sludge, and thus increasing the discharge concentration.

The SedVac Advantage

Eliminating frequent manual cleaning saved the Aqua America plant in Tiffin $5,000 per day. This not only allows for increased productivity but also keeps workers safe by removing personnel from potentially hazardous working conditions. Whereas traditional vacuum systems often require frequent running in order to reduce clog occurrences during heavy loading periods, SedVac only requires running once per day, providing additional cost savings.

Lastly, the plant experienced unexpected savings that were directly related to SedVac: The system allowed for a reduction in the frequency of filter backwashing. Because of the change from alum coagulants to DelPAC, the solids began settling at four times the previous rate. Therefore, instead of backwashing every 24 hours, the plant now only backwashes once every 120 to 168 hours, conserving 50,000 to 75,000 gallons of treated water per day.

Jim Welty, plant manager and field supervisor for the Aqua America plant in Tiffin, said, "I would recommend the [SedVac] system to anyone because not only did it reduce the sludge like we were told it would but we had other enhancements with lower TLC and THM numbers in our sedimentation basin." He noted that the system has been very reliable and has kept the plant in production.

It is clear that SedVac was the right solution for the challenges encountered by Aqua America. The system enabled the plant to save money, see results beyond their expectations and stay productive despite fluctuations in raw water quality.

About the Author: John Stevenson is a product line director at Brentwood. He has been with the company for two years.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles