Extend Bearing Life, Reduce Pump Life Cycle Costs with Oil Mist Bearing Lubrication

By Allan R. Budris

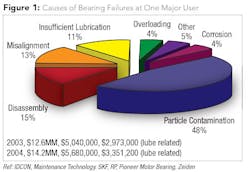

Because bearing failures are the second leading cause of pump failures/repairs (after mechanical seals), it seemed important to further expand on the many benefits and mechanics of “oil mist bearing lubrication,” initially touched on in my February 2008 and August 2010 WaterWorld columns. As shown in Fig. 1 (which is based on a typical application), 48 percent of bearing failures are caused by particle contamination, 11 percent due to insufficient lubrication, and 4 percent due to corrosion. This equates to almost two-thirds of bearing failures that could be prevented with a superior lubrication method, such as oil mist (coupled with a synthetic lubricating oil).

Although oil mist lubrication systems are more common in chemical and petroleum plants, their many benefits should also help extend the life of pumps and motors in water and wastewater facilities.

What Is Oil Mist Lubrication?

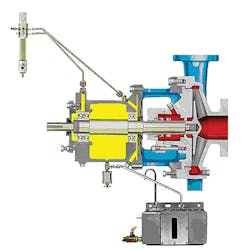

Oil mist lubrication is a centralized system (see Fig. 2) that utilizes the energy of compressed air to produce a continuous feed of atomized lubrication oil. This atomized lube oil (1 part oil to 200,000 parts air), or “oil mist,” is conveyed by the carrier air, usually dry air from the plant instrument compressor or dry plant air, to multiple points through a low pressure distribution system.

Centralized systems use this compressed air to feed the atomized lubrication oil at a low pressure (20” H2O). The oil mist then passes through a reclassifier nozzle before reaching the end point (typically an anti-friction bearing) which is to be lubricated. Different reclassifier nozzles are used at the injection points for different applications. Reclassifiers change dry oil mist into wet oil mist. At its destination, the oil mist provides either only a protective, or both a protective and lubricating environment.

Oil mist systems can be broken down into three basic types:

- Wet sump: Used on top of the primary lubricating oil in the bearing housing sump primarily to protect bearings from corrosion.

- Dry sump: used for bearing lubrication, particle contamination and corrosion protection. There are two types:

- Open loop: Vapors exhaust/exit to the atmosphere through the bearing housing shaft seals and/or vent

- Closed loop: Exit vapors are collected, treated and recycled. The spent ‘lean’ mist (mostly air) is drawn into a lower pressure return header (see Fig. 3), and finally to an oil knock-out drum.

- Long-term storage of pumps and motors: Oil mist is used to protect against corrosion. Benefits include stand-still protection of installed pumps and electric motors against corrosion and dirt ingestion.

Oil mist units come in different sizes and with capacities that vary by orders of magnitude. Small units serve perhaps only one or two critically important pumps, consuming no more than 2.1 gallons of oil per pump per year. Medium size units often serve 15 or 20 pump sets. Plant-wide oil mist systems allow the oil mist to travel as far as 600 ft (approximately 200 m) from a centrally located oil mist console to the most distant pump.

Oil mist bearing through-flow (see Fig. 4) represents “Best Technology.” This through-flow is recommended wherever feasible, regardless of whether the machine is an electric motor or a pump. Oil mist can be used to lubricate and preserve many types of machinery, in addition to pumps, especially motors. Multiple uses make it easier to financially justify an oil mist system.

Purge Mist (Wet Sump)

Oil mist is used effectively as a bearing housing purge and, to a limited extent, as fresh oil make-up to the reservoir, mostly used for sleeve bearings. An effective purge will exclude atmospheric contaminants from the bearing environment. The purge mist must exist at a higher-than-ambient pressure. Typical applications include small steam turbines and cooling water tower gear boxes.

Pure Mist (Dry Sump)

Dry sump oil mist systems have many desirable features. They create an ideal lubrication environment, and are used with rolling element bearings of all types. Further, they do not maintain an oil level in the bearing housing. Rather, they use oil mist to provide the lubrication and there is no need to inspect and change oil in the sump. They also have no regreasing requirement and they ensure that metal surfaces are continuously coated with oil.

Dry sump oil mist can either exhaust to the atmosphere, be recycled, or be collected. U.S. regulatory agencies do not consider oil mist lubrication an air pollutant. They conclude that oil mist is not a vapor and therefore is not a contributor to air pollution. Still, modern plant-wide oil mist systems are closed-loop. It should be noted that closed loops can be easily retrofitted to existing systems. It not only eliminates virtually all stray mist and oil leakage but also makes possible the recovery, subsequent purification, and re-use of perhaps 90 to 97 percent of the oil.

This oil recovery helps justify superior and more expensive synthetic oil. It is recommended to use ISO Grade 32 or 68 synthetics lubes at locations that experience ambient temperatures below 40oF. Certain mineral oil base stocks promote the formation of wax platelets at low temperatures, which might plug the small bore passages in some reclassifier fittings. Figure 4 shows a single unit recovery system.

Technical Advantages of Dry Sump Oil Mist

Oil mist ranks near the top of the list of most reliable lubrication methods. The dry sump oil mist technique offers the following advantages:

- Bearing wear particles are not recycled back through the bearing, but are washed off instead.

- The need for periodic oil changes is eliminated.

- There are no oil rings whose wear debris might jeopardize bearing life.

- Typically, oil mist will cause bearings to operate up to 20oF cooler.

- Long-term oil breakdown, oil sludge formation and oil contamination are no longer factors affecting bearing life.

- The ingress of atmospheric moisture into pump or motor bearings due to daily solar heating and nightly cooling (which causes air in the bearing housing to expand and contract) is prevented by the pressurized oil mist.

- The proper amount of the correct, clean oil is applied continuously, so the internal metal surfaces are always coated with oil, which prevents corrosion.

- L10 bearing life is extended by factors of 3 to 6 (Source: Texas A&M University Research).

In addition, the service and maintenance requirements of modern oil mist systems are extremely low, which further lowers life cycle costs.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. He can be contacted via email at [email protected].

References:

1. Bloch, Heinz P. & Allan R. Budris. Pump User’s Handbook, Life Extension, Fourth edition, Fairmont Press Inc., 2014.

News Briefs

WASHINGTON, DC, diversion sewer project earns national recognition

CDM Smith of Fairfax, Va., has earned a National Recognition Award for exemplary engineering achievement in the American Council of Engineering Companies’ (ACEC) 49th annual Engineering Excellence Awards for the Tingey Street Diversion Sewer in Washington, D.C.

As part of DC Water’s strategy to reduce combined sewer overflows to the Potomac and Anacostia Rivers and Rock Creek, the 72-inch diameter tunnel captures and stores wet weather flows for treatment at the Blue Plains Advanced Wastewater Treatment Plant. To minimize impacts to a new mixed-use redevelopment project and two subway line crossings, the tunnel was installed on an expedited schedule using a laser-guided micro-tunnel boring machine. Two diversion structures were built to direct flow away from the Anacostia River and into the tunnel. A 36-inch pipe from one of the structures was installed using pilot tube tunneling methods to minimize disturbance to a nearby roadway. Instrumentation installed in two underlying subway tunnels provided real-time monitoring of structural conditions.

ACEC recognized 151 projects throughout the nation and the world as preeminent engineering achievements, and all were eligible for top national honors. Judging for this year’s awards - known industry-wide as the “Academy Awards of the engineering industry” - took place in February, conducted by a panel of more than 30 engineers, architects, government officials, media members, and academia. Award criteria included uniqueness and originality, technical innovation, social and economic value, complexity, and success in achieving goals.

Winners of the top national awards will be revealed at the annual Engineering Excellence Awards Dinner and Gala, a black-tie event to be held Tuesday, April 19, 2016, at the Marriott Wardman Park Hotel in Washington, D.C.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles