Optimizing Biological Systems to Treat Wastewater

In 2011, the small city of Deport in northeastern Texas began experiencing serious problems with its four-lagoon wastewater treatment system. Effluent was exceeding permitted discharge requirements for Escherichia coli and foul odors were developing as a result of high BOD and TSS accumulation in the lagoons. The city faced penalties from formal enforcement actions taken by the state.

As an interim solution, the city installed a $5,000 aerator in its aeration basin and a second, older aerator in one of the lagoons. Bacteria and enzymes were likewise added to the lagoons in an attempt to address the mounting issue.

These efforts had limited effectiveness, forcing Deport officials to seek viable, long-term solutions for meeting permitted discharge requirements and eliminating the nuisance odors. Continued dredging of the built-up sludge was considered, along with the possibility of constructing a small mechanical treatment facility, but both processes proved to be cost-prohibitive.

During its search for answers, the Deport team was introduced to the Blue Frog System by Absolute Aeration. The Greeley, Colo.-based company claimed that its system would enable the city to meet its effluent discharge limits (excluding E. coli) while digesting accumulated and incoming sludge at a controlled rate to minimize odors and control nutrient release.

In January 2012, the city installed the Blue Frog system at a cost of roughly $140,000, with projected annual operational and maintenance expenses of approximately $350. The design objectives were based on a 12-month return on investment.

The revolutionary hybrid aeration technology utilizes natural biological processes to enhance organic sludge digestion in situ. Known as “biodredging,” this scientific advance selects for the indigenous bacteria that are in the lagoon and are already adapted to local conditions and the wastewater substrate.

This organic biological control mechanism is ideally suited for the natural fluctuations in flow that characterize municipal sewage lagoons like those in Deport. As an added benefit, biological control is much more cost-effective due to the reduced energy costs associated with traditional oxygen-adding strategies, which require significant aeration horsepower.

In Deport, the design strategy was to digest recalcitrant sludge that had built up over two years at the bottom of the lagoon and to keep up with the new incoming solids daily to eliminate any further accumulation, ultimately increasing the pond’s retention capacity. The system was also designed to meet the monthly permitted discharge requirements for BOD (30 mg/L), TSS (90 mg/L), pH (6.5-9) and DO (> 4 mg/L).

The city, now home to roughly 600 residents, has four wastewater treatment lagoons that can treat 0.2 MGD. The system discharges to Mustang Creek, which flows into the Sulphur River Basin. Pond #1, which was aerated, is roughly 10 feet in depth, while pond 2 is 8 feet deep and the other two ponds are about 4 feet deep and quiescent. Ponds 3 and 4, in particular, had a high level of solids accumulation and foul odors.

The Blue Frog installation process began with an engineered floating boom called a Continuously Stirred Tank Reactor (CSTR), which is used to create hydraulic walls to redirect horizontal flowing water downward to the anaerobic zone. The CSTR functions as an engineered tank that concentrates bacteria and solids at the bottom of the lagoon. The CSTR is placed over the inflow and serves as an equalization tank equalizing the influent, a selector tank that selects for sludge-digesting bacteria, and an incubation tank that produces a large population of high-quality microbes.

The bacteria form synergistic anaerobic biofilms in tight, mineral-based granules, creating a granular sludge bed reactor over the entire bottom of the lagoon. Surface biosolids are delivered to the sludge bed, liquefied and then turned into gas by the bacteria immobilized in and on the granules. Produced gas rises and gently mixes the water column, continuously feeding the granules to increase their productivity. Once the granular sludge bed reactor is established, bacteria will grow and die in direct response to the level of nutrients coming into the lagoon.

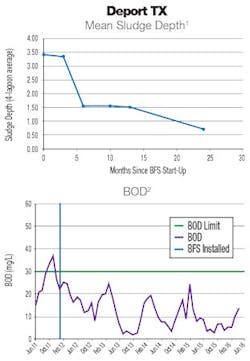

Within weeks of installation, the Blue Frog systems had noticeably reduced the accumulated sludge. After 18 months, BOD and TSS levels were measured at less than half the permitted limit. Within two years, the accumulated sludge had been cut by 79 percent, and BOD and TSS were reduced to a new, much lower equilibrium. And even though the system was not designed to meet the E. coli limitations, the bacteria-destroying process also reduced the E. coli concentrations below the permitted level of 126 MPN.

Roughly three years after installation, a startling change occurred when the four-foot-deep facultative ponds suddenly turned clear and the top of the sludge blanket changed from black to tan.

The facultative ponds in Deport have a modified flow pattern called “perimeter flow,” which brings low-oxygen water across the pond surface to the berm, then down the berm, across the sludge face and then back to the circulator inlet. The effect is to add limited oxygen to the perimeter surfaces and not add oxygen to the middle of the pond. Limiting oxygen selects for facultative bacteria over aerobes. Facultative productivity at the sludge surface increases, enabling the sludge to be digested faster. When aerobes are not selected, TSS is not produced and the pond clarifies.

Practically, the anaerobic sludge blanket gets coated with an aerobic covering and the blanket surface turns from black to tan leaving a visually clear supernatant. Once the sludge surface is aerobic and the supernatant is clear, benthic algae populate the surface and add additional oxygen at the sludge blanket surface. This change is dramatic and it occurred over a 7-day period.

The metrics at Deport’s wastewater treatment facility continue to improve each year. As of June 2016, the sludge depth has been reduced to roughly six inches.

“We achieved very impressive results in Deport in just a few months, and four years later, it remains a case study in how municipalities can solve their accumulated sludge problems without using chemicals or resorting to expensive mechanical dredging,” said Rick Roberts, CEO and co-founder of Absolute Aeration. “The Blue Frog System has created a paradigm shift in wastewater treatment for municipal plants. By harnessing nature’s power to digest organic sludge in situ, we save cities money, help preserve the environment and avoid the need to replace their lagoon systems with activated sludge plants.”

The Blue Frog System Technology is a hybrid anaerobic digestion system that creates radial outflowing currents increasing the biological activity utilizing minimal energy consumption. To learn more, call (888) 237-7912 or visit www.bluefrogsystem.com.

Notes

1. Data in the included figures is based on information provided by the city of Deport, Texas.

2. The BOD, TSS and E. coli charts show the effect of spring turnovers but the ponds recover quickly because the absolute amount of sludge is less than six inches.

3. The Blue Frog System was not designed as a pathogen kill step for Deport, Texas.