Underground Detention System Solves Sainte Agathe's CSO Woes

By Tom Kostarides and Brian Maguire

Ville de Sainte-Agathe-des-Monts (Sainte Agathe) is a popular four-season tourist destination in the Canadian province of Quebec, within the Laurentian Mountains. Sainte Agathe was first settled in 1849 and saw rapid development in the early 1900s. As a historic city, the town’s sewer system is a combined sewer system that conveys both sanitary sewer and stormwater discharge to its municipal wastewater treatment facility.

On February 17, 2009, the Canadian Council of Ministers of the Environment (CCME) adopted the Canada-wide Strategy for the Management of Municipal Wastewater Effluent. Although Quebec has not yet formally signed on to the strategy, it has declared its support of the strategy’s technical content and wishes to ensure that the criteria for land development or redevelopment projects minimally integrate the Canada-wide overflow standards established by the Strategy.

In order to protect the town’s environment and meet the intent of the combined sewer overflow (CSO) regulations adopted by the CCME, Sainte Agathe commissioned a large-scale combined sewer detention facility adjacent to its municipal plant along the Riviè;re du Nord. The detention facility is designed to store 260,000 gallons of stormwater discharge during peak flow events. This additional storage capacity effectively eliminates CSO events during all but the largest storms and serves to protect the town’s pristine streams and rivers.

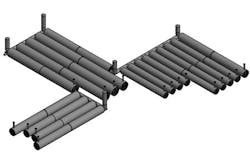

Variable rock table and existing infrastructure constraints required that the system utilize multiple diameter barrels in a three-field approach. Uponor worked with the engineer of record at SMi Consultants to develop a system that would provide the required volume of storage while minimizing rock excavation and impacts to the plant’s existing infrastructure.

The detention system was fabricated from Weholite RSC 250 profile wall polyethylene pipe manufactured in accordance with ASTM F894. Barrel geometry included 5-, 6-, and 7-foot-diameter barrels connected by a continuous 36” header system with 36” manhole access risers. Bulkheads were manufactured from Wehopanel P120H profile wall panel and reinforced with HDPE encapsulated steel beams.

Large-scale underground detention systems require a comprehensive engineered systems approach to design. Uponor evaluated the Sainte Agathe system using a two-dimensional (CANDE) finite element analysis routine that accounts for the soil-structure interaction under the applied loads. Uponor also performed a three-dimensional finite element analysis of the system to analyze bulkhead deflection and reinforcement requirements.

Uponor worked with distribution partner ISCO and the general contractor, Inter Chantiers, to coordinate the detention system’s fabrication schedule, installation, and field welding details.

All joints, fittings, and fabricated elements were extrusion-welded to ensure a leak-free system was achieved. The fully assembled system was tested under a 24-hour exfiltration protocol and certified to be leak-free. Upon successful completion of the project, Alexander Foisy, president of Inter Chantiers, commented, “Inter Chantiers is proud to successfully achieve this project on schedule and on budget. Our team truly believes that we not only ‘built another infrastructure project’ but we did so in a durable manner. I am proud to have contributed to my community by participating in this project.”

About the Authors: Tom Kostarides is Uponor’s Quebec Sales Manager. Brian Maguire is Uponor’s Engineered Systems Manager. Uponor’s systems are manufactured under strict polyethylene welding standards and can be custom fabricated to meet the needs of any application. All fabricated structures are pressure-tested prior to shipment. In-field extrusion welding is performed by Uponor’s certified technicians to ensure that a leak-free system is achieved. For more information on Uponor’s HDPE solutions, visit https://infra.uponor.ca.