By Friedrich Edelmeier

Filtration system operators and designers are under constant pressure to enhance the efficiency of their systems. The faster they can move fluid through the system the better, as long as they’re not sacrificing particle filtration in the process. This has traditionally been a tall order given the existing physical limitations of a filter element, which will be a defined size based on the equipment it’s used in. It can only have a defined number of pores, and therefore open area, based on its dimensions, and designers can typically only alter the pore size of the filter to affect its flow rate. Yet, even when altering a filter’s pore size, designers are bound by simple physics. You can’t force any more fluid through a hole than what its physical size allows, and the smaller the hole, the lower the flow.

Because the flow rate through a filter is so closely tied to the total open area of the filter’s pores, the best way to enhance the efficiency of the filter is to increase that open area by adding more pores and the only way to do that is by going 3-D.

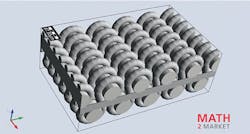

By adding an additional layer of weaving, a 3-D filter cloth like the MINIMESH RPD HIFLO-S metal woven filter cloth doubles the number of pores available for the given surface area of the filter element. Doubling the pores doubles the flow capacity, just as in the case of drilling the second hole in the 2-D sheet metal noted above. The 3-D weaving principle is different from simply stacking two 2-D filter cloths on top of one another, which would just yield a double filter with no flow improvements. Instead, the MINIMESH RPD HIFLO-S uses a reverse plain Dutch weave that essentially offsets the top and bottom layers of pores, effectively creating twice as many pores within a single 3-D filter element.

In addition to enhancing flow, doubling the number of pores for a given filter dimension also has important implications for managing pressure within the filtration system.

About the Author: Friedrich Edelmeier is vice president of HAVER & BOECKER, the parent company of W.S. Tyler. To learn more, visit wstyler.com or call (800) 321-6188.