Advanced aerobic digester solution saves energy, removes nutrients, and lowers operating costs

By Sarah Elger

Aerobic digestion is the most commonly used method of biosolids stabilization in the United States. Unfortunately, most of the processes associated with aerobic digestion are not optimized, resulting in excessive energy consumption, high operating costs, and significant nutrient loads that are returned to the main treatment plant during biosolids dewatering.

The City of Green Lake, Wis., wastewater treatment plant uses a continuous feed ICEAS advanced SBR system with aerobic digestion.

The Energy Efficiency Imperative

Continually rising energy prices are putting growing pressure on wastewater treatment plant operators to improve operational efficiency. Typically, energy efficiency efforts focus on biological treatment aeration in the secondary treatment process. However, aerobic digestion aeration is the second most energy-intensive process in a plant, often consuming hundreds of thousands of dollars in energy.

Additionally, increasingly stringent environmental standards mean that effluent nutrient limits are becoming more common, with about half of all U.S. states now requiring numeric nutrient criteria designed to protect surface waters from eutrophication.

These factors are driving an increased focus on redesigning treatment plants to optimize the process used to remove nitrogen and phosphorus. A common approach is to adjust the secondary treatment system. However, the aerobic digestion process can produce up to 50 percent of the total nutrient load to a treatment plant via return streams from biosolids dewatering, impacting the effectiveness of this approach. Furthermore, as most aerobic digesters include manual telescoping valve decanters, operators are often required to perform manual decanting on a daily basis. As such, it is imperative that the aerobic digestion process also be optimized.

Inefficient wastewater operations result in excessive energy consumption, high operating costs and harmful greenhouse gas emissions related to electricity generation. A report by water technology company Xylem, Powering the Wastewater Renaissance, highlights how increasing energy efficiency through the adoption of readily available wastewater management technologies can reduce related emissions by nearly half. The analysis also suggests that much of this reduction in emissions can be achieved at a negative or neutral cost.

Solution for Efficient Aerobic Digestion

An integrated system solution for aerobic digestion can help wastewater treatment plant operators comply with regulations while minimizing operating costs. New, energy-efficient aerobic digester solutions combine equipment, controls and services to ensure wastewater treatment plants meet current and future U.S. Environmental Protection Agency (EPA) effluent and biosolids regulations, while simultaneously reducing operational costs.

One such system is Xylem’s Sanitaire Vorelodos, an automated, intelligent and efficient aerobic digester solution using a process performance optimizer system with a controller specifically designed to remove nitrogen and phosphorus. The system also lowers chemical use as a result of alkalinity recovery and a reduction in the amount of phosphorus that is returned to the main plant. An automated decanting feature and aeration control mean that staff time can be invested in other activities.

Optimizing Aerobic Digestion at Green Lake Wastewater Treatment Plant

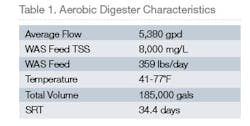

The City of Green Lake, Wis., wastewater treatment plant uses a continuous feed ICEAS advanced sequencing batch reactor (SBR) system (average flow = 0.2 million gallons per day [MGD]) with aerobic digestion. The aerobic digester includes fine bubble diffusers and positive displacement blowers. Digested biosolids are sent to a belt filter press for dewatering and, ultimately, for land application.

The digester has four zones operating in series: two in both the east and west digesters. Waste activated sludge (WAS) is automatically pumped from the ICEAS system into the east digester every two hours. The supernatant from the digester is returned to the SBR through the telescoping valve and is manually initiated four days per week. A sludge pump is used to remove sludge from the west digester once a week.

When the Sanitaire Vorelodos aerobic digester was installed here, it resulted in a more than 90 percent reduction in soluble phosphate returned to the plant, a 50 percent reduction in chemical consumption in the main process, and a 95 percent decrease in energy consumed by the aerobic digester when compared to the continually aerated digester.

During the pilot application, from January 2016 to March 2017, sensors measuring NH4, NO3, K, DO and ORP were installed in the east and west digesters. Additionally, an orthophosphate (PO4) analyzer (P700 model) was installed in the east digester (see Table 1).

Green Lake’s existing aerobic digester was upgraded to the Vorelodos aerobic digester, equipped with an OSCAR advanced process performance system with customized DINO controller, which automatically adjusts the required aeration time in the digester based on potassium readings. The controller alternates aerobic, anoxic and anaerobic conditions in the digester to optimize total nitrogen and phosphorus treatment while minimizing energy consumption.

The system resulted in a more than 90 percent reduction in soluble phosphate returned to the plant, a 50 percent reduction in chemical consumption in the main process, and a 95 percent decrease in energy consumed.

Improved Nutrient Removal, Energy Savings

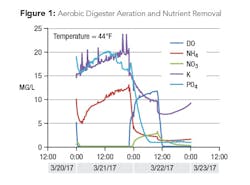

The process performance system with customized controller enabled biological phosphorus removal in the digester, reducing the amount of PO4 returned to the main plant by more than 90 percent. Figure 1 shows one aerobic period where soluble PO4 decreased more than 95 percent due to biological phosphorus uptake, resulting in a significant reduction in the amount of phosphorus returned to the ICEAS process via decant or solids dewatering. This reduction helped the plant reduce chemical consumption in the primary treatment process by 50 percent, while still meeting the effluent phosphorus permit of 1 mg/L.

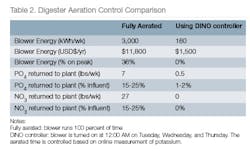

The DINO controller also achieved 100 percent reduction in NO3 returned to the main treatment process when compared to the previous operation, which was continuously aerated. Digester blower energy consumption was reduced by 95 percent compared to previous operation. Blower energy was cut from 36 percent to 0 percent on-peak, reducing demand charges and the unit cost of energy (see Table 2).

Conclusions

The Vorelodos aerobic digester, equipped with the OSCAR system with DINO controller, improved digester performance by reducing by more than 90 percent nutrients (nitrogen and phosphorus) that were returned to the primary treatment process, and by lowering energy consumption by 95 percent, supporting a more sustainable and efficient operation.

Glen McCarty, director of public works at the Green Lake Wastewater Treatment Plant, said, “Permitted levels of nitrogen and phosphorus in effluent water are becoming ever stricter in an effort to protect surface waters from eutrophication. At the same time, plants are required to reduce energy and chemical consumption and are often challenged with limited time and staff. Sanitaire Vorelodos enabled us to do more with less.” WW

About the Author: Sarah Elger is a global product manager at Xylem – Sanitaire Products and is responsible for the biological treatment product lines. She holds a Master of Science degree in environmental engineering from the Milwaukee School of Engineering, and a Bachelor of Science degree in engineering mechanics and astronautics from the University of Wisconsin. Elger is also a registered professional engineer in the State of Wisconsin.