By Jason Ziemer

Water treatment chemicals play an important role in maintaining public health and environmental quality. They are utilized to reduce pollutants in industrial wastewater, to remove contaminants from municipal sanitary sewers, and to improve the quality of our raw drinking water. There are dozens of commonly used water treatment agents, most of which are inorganic or synthetic polymers such as alum (aluminum sulfate), ferric chloride and polyacrylamides. Each of these polymers has advantages and disadvantages when it comes to applicability and pollutant removal efficiency.

A relatively new biopolymer, chitosan (ky-toe-san), shows superior performance where many conventional polymers fail. It is a versatile polymer with applications in water treatment, biomedical and dietary supplement industries.

Chitosan is made from chitin, which is a naturally occurring biopolymer derived from recycled crustacean shells, insect exoskeletons or fungi. Chitin is harvested from the seafood processing industry throughout the world to supply the base material for the manufacturing of chitosan.

Because chitin and chitosan are products of nature, the quality and characteristics can vary according to:

- Geographic source

- Species of crustacean

- Habitat factors (temp.)

- Chitin extraction methods

- Chitosan manufacturing process

- Quality assurance procedures

These factors can influence the quality of the chitosan produced. The quality of chitosan is typically related to molecular weight and cationic activity level (strength). The bottom line is that a high-quality chitosan may be two to three times as effective as a low quality chitosan product. When it comes to water treatment, the higher the grade of chitosan used, the less chemistry needs to be applied to the water to achieve the desired results. This leads to a lower overall chemistry cost of the water treatment process.

Chitosan is used as a flocculant in water treatment processes, but there are other synthetic flocculants available as well. Often times these synthetic flocculants are more “aggressive” and can be less expensive to use. Although these other flocculants can often bind organic molecules and other pollutants better than chitosan, they do have a residual impact on the environment. Chitosan, however, will biodegrade in the environment over periods of weeks or months rather than years.

All flocculants have their place in the market. However, where and how they are applied can make a significant difference in performance and cost.

Chitosan Enhanced Sand Filtration (CESF) uses sand as the filtration media to strain the floc’d particles out of the water. Regulatory agencies, such as the Washington State Department of Ecology, recognize CESF as one of the preferred methods of treating stormwater for construction and industrial sites.

Chitosan is also classified as a biological treatment for stormwater application in some states in the Great Lakes region, and several municipalities in Canada have specified that chitosan is the only flocculant that can be used for stormwater applications.

In general, industrial and construction projects have seen a rise in the use of flocculants to achieve the stringent water quality parameters of their sites. The technology is capable of removing turbidity, metals, nutrients and other pollutants at demonstrated removal rates of over 93%.

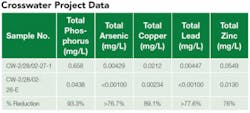

A unique aspect of chitosan is its ability to chelate dissolved metals in water. Chelation is a process by which multiple binding sites along the polymer chain bind with the metal to remove it from a solution. This attribute has increased chitosan use for difficult industrial stormwater and wastewater applications. In many of these cases, conventional source controls and BMPs have simply not been able to reduce the contaminant levels to the degree that the discharge water quality is in compliance. Studies have shown that chitosan was able to reduce metal concentrations in water by over 75% to non-detectable limits in applications such as remediation sites, log sort yards, mining industry and boatyards.

There are literally hundreds of polymers that act as flocculants and many are used in wastewater treatment and various other processes. However, very few, if any, have the ability to biodegrade in the environment like chitosan, making it a sustainable, environmentally viable alternative to chemical treatment of stormwater and other water sources.

About the Author:

Jason Ziemer, formerly a principal of Clear Water Compliance Services Inc., has spent nearly a decade working with erosion/sediment control and stormwater management of construction and industrial sites. He is currently vice president of technology and development for Worldwide Water Inc. (Lynnwood, WA). He can be contacted via e-mail at: [email protected].