Integrated UPS actuators support critical applications

A case study provided by Landeswasserversorgung, the water works in Stuttgart, Germany, outlines how, in service critical applications such as water utilities, valve actuator operation can be assured, even in the event of mains power supply failure. Details are provided of two German reference sites that demonstrate what can be achieved using integrated actuator/UPS(uninterrupted power supply) systems.

A review of the water utility in the Stuttgart region of Germany describes how an integrated actuator/battery/power inverter solution can be used with a three-phase supply system. The study also illustrates how single-phase actuators, chosen for their low power consumption, lead to significant cost savings. Additionally, the application demonstrates how integrated actuator/UPS equipment is used to provide mains water system control, without potentially damaging pressure surges (water hammer) - this is achieved by the use of variable speed valve closure in the event of a burst pipe, even when plant power is lost.

The Landeswasserversorgung (LW) regional water supply company is one of the largest district organizations of its kind in Germany. The utility has a long and prestigious tradition and supplies over three million people in about 250 towns and municipalities in Baden-Wuerttemberg. The supply company’s annual output exceeds over 95 million cubic meters of drinking water.

The network for the extraction, treatment and distribution of drinking water is continuously being expanded, modernized and upgraded using state-of-the-art technology. The objective of this ongoing program is to provide highly reliable, premium quality drinking water.

Continuous Service

When designing a plant or installing/selecting equipment, requirements for water supply reliability have to be the primary consideration. With this in mind, plant monitoring and operation of safety relevant equipment has to be ensured in the event of any failure, such as disruption of the public electricity network. To ensure that continuous service is provided, battery backup emergency power supply systems and, on occasion, power inverters have been used.

After a merger with the Blau-Lauter group in the mid-1990s, LW modernized the reservoir system in the Kirchheim area. This included the upgrade of electric installations encompassing battery backup emergency power and replacement of electric actuators used on the pipeline system shutoff valves. A strategy of harmonization of actuator types had an impact on both the former Blau-Lauter group and other regions within the LW.

For this reason, a market review of electric actuators was performed to find new, powerful actuators which could be integrated as an alternative to the models that had previously been used.

New Actuator Solution

The new actuation solution requirements for LW included use of a supply voltage of 230/400 VAC, compatibility with the LW communication standards and availability of multiple options including torque control and positioning times.

During the market review, particular emphasis was put on the actuator power supply. Actuators used in conjunction with pipe burst monitoring functions must be equipped with battery backup power inverters, which may be operated for short time periods in the event of power supply failure.

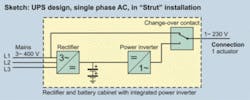

As power inverters for single-phase AC voltage offer significant cost savings compared to three-phase inverters, only single-phase AC actuators were tested. In addition to the review of product specifications, six-month product testing was carried out on an actuator mounted on a pressure control valve. With successful analysis and testing results, the decision was taken to adopt actuator products offered by SIPOS Aktorik.

One of the key benefits of these actuators, which assisted selection by LW, is the absence of a startup current spike. This is a feature of the integrated converter technology. In addition, this enables use of a robust three-phase asynchronous motor even when using a single-phase AC power supply to the actuator.

As a result of the market review, and as part of the modernization program, a number of installations were equipped with SIPOS actuators/power inverters within the area of the former Blau-Lauter group. In the remaining LW regions, other SIPOS actuator models have been increasingly adopted. A preference has been shown for actuators with single-phase AC voltage supply.

Only larger valves requiring high closing torques have been equipped with actuators using the more costly three-phase AC connection. On installations where a larger number of actuators were used, the Profibus DP interface was selected as an alternative to adoption of conventional control technology.

Reference sites

Two LW reference sites detailed below illustrate use of SIPOS actuators in combination with UPS systems and are good examples of the wide ranging capabilities of variable speed actuation solutions.

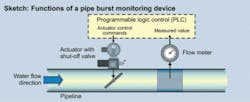

The “Kupplung Strut” installation is a simple pit with a junction room where pipe bursts in the LW mains are monitored. In this application, a programmable logic controller (PLC) records the flow rate in the mains and compares the measured value to a set limit value. In the event of a pipe burst, flow rate increases rapidly and exceeds the set limit value. The PLC commands the actuator to close the shutoff valve. The water flow to the damaged point is shut off and, to ensure critical operation even during a power failure, the actuator is directly supplied via a battery backup power inverter.

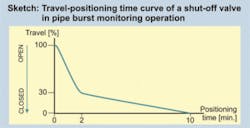

To prevent pressure surges (water hammer) within the pipes when opening or closing the shutoff valve, the actuator is operated according to a stroke-positioning time curve. In this case, a total running time of 10 minutes from open to close has been selected. The actuator operates the valve in the range of opening angle 100%-30% Open within two minutes and the more critical travel of 30% to 0% Open over eight minutes.

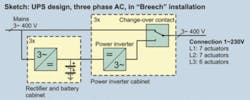

The “Behälter Breech” installation is an intermediate storage tank within the mains with flow meter, power generation system, inflow controls and pipe burst monitoring functions. In total, 20 valves are currently installed within this station operated by single-phase AC actuators. The control is implemented via Profibus DP.

In this more complex installation, a three-phase power inverter with sufficient power capability is used to ensure operation of the relatively large number of actuators in the event of a power failure. The single-phase AC actuators are assigned to the individual phases of the three-phase power inverter according to their power consumption. This configuration guarantees an evenly distributed load to the three-phase power inverter.

Conclusion

Eight years of field experience with several hundred actuators supplied to LW has demonstrated that a high level of operational reliability can be attained by using a combined technology approach to actuator solutions. These technologies are battery backup power inverters for emergency power supply to the actuator and travel-positioning time function to prevent pressure surges and consequently valve/pipe-work damage.

null

null

null

null