Dynamic Pressure Control Enhances Urban Water Management

Advanced instrumentation and SCADA solutions offer a base for more reliable, efficient operation of water piping systems and major financial benefits, both important to utility management in urban settings. They offer a means for increased productivity, help reduce failure events and lead to minimized potable water losses.

In many of the world’s urban centers, water scarcity prevails. At existing water rates, demand for water exceeds supply - mainly during peak hours of the day and, in many cases, during the entire day and even for the whole dry period of the year. Despite costs and water availability, many cities suffer from high levels of Unaccounted-For Water (UFW), as a result of physical losses as well as administrative mismanagement.

This UFW is one of the main causes for inappropriate management of urban water systems, leading to water scarcity and financial problems that prevent needed liquidity and capital generation to enable utilities to tackle and solve these problems. Often, piping networks are old and worn, while financial means to replace large sections of the network are unavailable, as this rehabilitation calls for huge budgets.

There are a number of effective measures a utility can implement to minimize leakage problems and enhance overall water conservation. These solutions integrate and enhance reduction of water leaks and UFW by means of “dynamic pressure” regulation between urban zones. This is done during prioritized daily and weekly hours and off-peak weekend flows. It’s highly effective in providing adequate water supplies in more arid areas, for fire protection as well as irrigation of city parks - all of which can be taken into consideration as well to reduce losses.

This article describes two important measures to improve overall monitoring, control and management: 1) centralized data communications based on supervisory control and data acquisition (SCADA) technology, and 2) integration of “zonal pressure control” methods with the SCADA solution. Both have proven key to effective distribution system management and maintaining a 24-hour-a-day reliable water supply, while minimizing related water and financial losses due largely to aging and leaking piping networks.

Benefits of SCADA Solutions

Use of SCADA systems and remote terminal units (RTUs), combined with wireless communication, perform the monitoring and control functions as specifically required for each field site. Obviously, every function performed at a remote site must be linked to a specifically defined operating or cost benefit, as otherwise it makes no sense to implement that function. As a result, utilities may achieve reduction in their electric power bill, minimize failures, and gain more effective and faster handling of critical events. In addition, utilities benefit from more convenient work environments for maintenance teams and modernized operations under their responsibility.

SCADA systems help achieve optimal water distribution by adding new features to the system, such as: level and flow monitoring, pump operation sequencing, electric energy consumption monitoring, historical scenario analysis (audit trail) and “dynamic pressure control” (DPC) capabilities. Sensors for flow monitoring, usually installed next to valves, collect flow and other information, which in turn is communicated via RTUs to a SCADA control center. Using this data, the SCADA system may maintain stable pressure, help optimize flow rates and also:

- Optimize pressure level as needed and thereby minimize leaks through hundreds or thousands of non-identified (difficult to repair) pipe breaks and smaller holes.

- Reduce misuse/excessive use of water due to unneeded high pressure provided to domestic and commercial consumers as well as industrial users, parks and gardens.

- Record flow and pressure data in each section for off-line analysis for operational optimization and future planning.

Pressure Control along Pipelines

Careful pressure and transient analyses are needed to understand the magnitude and future potential of this problem and, if necessary, determine how pressure should be adequately controlled using real-time measures. Hydraulic engineers have numerous solutions, available equipment and operational alternatives to consider when developing pressure and transient control strategies. Here, we focus largely on excessive pressure, which is a common problem occurring in water pipelines leading to increased leakages and system failures.

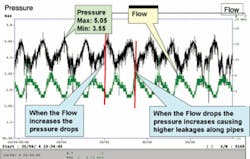

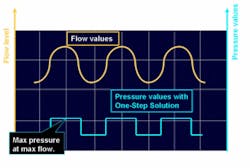

Figure 1 illustrates a typical pressure situation along pipelines in urban areas as displayed on the SCADA control center screen.

In this operating mode, whenever flow is lower than the estimated maximum due to low demand, there’s a build-up of excessive pressure along the pipeline that causes increased, unnecessary water consumption and losses, and, occasionally, new pipe breaks.

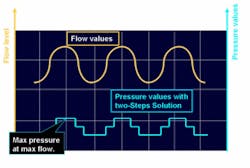

Conclusions obtained from analyzing Figures 1 and 2 leads to potential implementation of an improved operating scheme for urban water systems. Obviously, the design needs to ensure that during the time when the flow reaches its maximum level, there will be adequate pressure to serve all customers connected to the water pipeline, also taking high-rise buildings into consideration.

The solution to this challenge is to reduce the pressure along the pipeline during the time when the flow drops due to reduced demand - such as weekends in industrial areas and late night in residential ones. Reducing pressure along the pipe helps minimize water leaks through difficult-to-find holes as well as the probability of causing new breaks along the pipeline.

Note: It’s important to remember that in many countries fire trucks connect to the water pipe and the system must ensure minimum pressure for fire hose use.

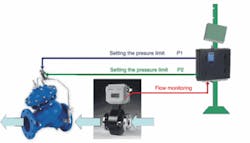

Implementing water pressure control using dynamically controlled pressure reduction valves (PRV) requires installation of flow meters along the pipeline, which in turn are monitored by RTUs. Each meter records the flow into a “metered area” with a permanently defined zone. This can be done using a SCADA system with a relatively low investment. Adjusting pressure according to dynamically changing conditions throughout the day and from season to season is an efficient tool that contributes greatly to several aspects of the system’s operation, such as:

- Allowing for more efficient use of existing resources

- Delaying investments in renovations

- Deferring investments in development of new water sources and pumping stations

- Minimizing failures results in reduced maintenance costs, and

- Helping extend the lifespan of the system

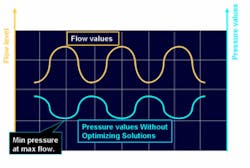

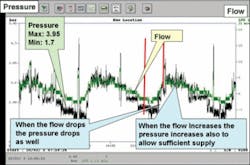

Figure 3 illustrates the challenge to providing adequate pressure to all customers connected to the pipeline, while each building is at a different distance from the source of the supply source. The reservoirs and main valve can be located in hilly areas, which affects actual pressure at each point. An optimal solution requires segmenting the pipe into zones and adding multiple PRVs tuned to optimal pressure outputs at a specific point.

Figure 4 illustrates a system that includes a flow meter that monitors actual demand. Based on this and parameters received from the SCADA control center, its role is to determine the optimal setting for output pressure from the PRV. Via special programming, the RTU output controls the solenoid, which regulates the output pressure from the valve.

Note: As operating the PRV via the small solenoid requires little electric power, the RTU may optionally receive its power from a solar panel and battery or from locally supplied AC power.

As seen on the chart, the point of maximum flow (time 12:00) is also the point of maximum pressure at the output of the PRV, the same value as shown in Figure 3 above. Here, however, when the flow drops during the night (24:00) due to low demand, the pressure is reduced to the minimum level needed to satisfy the “most distant” customer. This minimum value is much lower than the value seen in Figure 3.

NOTE: Here, the PRV has two solenoid-controlled devices, allowing it to set dual pressure set-points for more optimal operation.

Conclusion

A management decision to integrate and operate a SCADA system combined with dynamic pressure control (DPC) is aimed at improving efficiency and effectiveness of the utility operation. It involves use of: computer hardware, instrumentation and sensors, electric control panels, power monitoring devices, software programming, data communication, equipment, and system installation and commissioning. Appropriate selection of all SCADA related components may help achieve the system goals and expedite the return on investment (ROI).

Use of SCADA for management of water networks provides the means for more effective operation of a water utility, financial savings and other intangible benefits that can be as important as fiscal improvements. These, if possible, will lead to improved procedures that contribute to utility operations, achieve fewer supply interruptions and more effective handling of the water infrastructure. In addition to tangible benefits these solutions may promote more satisfied operators and maintenance staff, and enhance customer satisfaction.

Authors’ Notes:

Dan Ehrenreich is a marketing manager at Motorola Israel. With Motorola since 1991, he handles SCADA Business Development in Canada and Latin America and has presented papers on water, electricity and oil & gas SCADA solutions at conferences worldwide. Contact: +972 3 5658998 or [email protected]

Saul Arlosoroff, a director and committee chair for Mekorot, the national water company of Israel (Ret.), has over 40 years of experience in planning, design, execution and management of water resources management, water projects, sanitation and related environmental programs. He has coordinated and managed large scale operations in Israel,Asia, Africa and with the World Bank in over 40 countries. Contact: [email protected]