By Christie Zawtocki, P.E.

Soybean-based emulsion is proving to decontaminate groundwater more quickly than traditional remediation methods.

Managing groundwater contaminated with chlorinated solvents is one of the U.S. Department of Defense’s (DOD’s) greatest environmental challenges. A variety of chlorinated solvents have been used for years in both the military and commercial sectors for cleaning and degreasing products and equipment including aircraft engines, automobile and truck parts, electronic components and clothing. Widespread use of these compounds has adversely impacted the environment. Similarly, groundwater contaminated with perchlorate is another major environmental issue for DOD due to the use, release and/or disposal of solid rocket fuel and munitions containing ammonium perchlorate.

Base managers in charge of addressing groundwater cleanup have various options for remediating these contaminants, but many commonly-used technologies have high capital costs, need long-term operation and maintenance, and require long timeframes to achieve remediation goals. The challenge has been to find a powerful technology that’s regulator-friendly, can be implemented costeffectively, requires virtually no operation and maintenance, and can effectively remediate the contaminants of concern.

A New Bioremediation Formula

Remediation with emulsified edible oil substrate (EOS®) is a relatively new option for cleaning up groundwater contamination.

This treatment involves injection of a soybean oil-in-water emulsion into the aquifer to enhance in situ anaerobic biodegradation of the target contaminants. The emulsion, distributed by licensee EOS Remediation Inc., has been applied at dozens of military, commercial and industrial sites nationwide and is proving effective for remediating contaminants often found in groundwater at military installations, including chlorinated solvents, perchlorate and explosives such as TNT and RDX.

The substrate contains a proprietary blend of simple, inexpensive food-grade materials, consisting of soybean oil, lactate, surfactants, nutrients and vitamins. It’s engineered as a low viscosity micro-emulsion that’s easy to inject into the subsurface. Once injected into the aquifer, it quickly stimulates anaerobic processes and provides an extended, slow release of hydrogen and nutrients over time, resulting in long-term treatment (more than three years) with a single injection. Solutions-IES Inc., a Raleigh, North Carolina, USA-based environmental engineering consultant, has successfully applied EOS to remediate a source area at the Tarheel Army Missile Plant (TAMP) in Burlington, North Carolina, and to control plume migration in a barrier configuration at a rocket manufacturing facility in the state of Maryland.

Effective Source Area Treatment

At the TAMP site, Solutions-IES was retained by the Army Environmental Center to remediate a trichloroethene (TCE) source area. Historical use of chlorinated solvents at the site had resulted in soil and groundwater contamination. Existing pump-and-treat and air sparging systems were largely ineffective in reducing the groundwater plume after 10 years of operation. The Army needed to expedite cleanup to facilitate the sale of the property. The Remedial Action Plan consisted of source area treatment using EOS to achieve interim remedial goals for TCE followed by long term monitored natural attenuation to track further reduction of the chlorinated solvents to negotiated cleanup standards.

A 100-ft by 100-ft TCE source area was targeted for treatment. The aquifer consisted of clayish residual soils with bedrock present at 12-to-30 ft below ground surface (bgs), and the depth to groundwater was about 6-to-12 ft bgs. Solutions-IES which won a 2007 Ground Water Remediation Award for the project from the National Ground Water Association (NGWA) injected about 18,500-lbs of substrate concentrate through eight injection wells to treat the source area. The wells were installed about 30-to-35 ft apart, and a temporary recirculation system was used to distribute the emulsion throughout the treatment zone.

The EOS injection at the TAMP facility was successful in establishing anaerobic conditions and reducing concentrations of TCE to achieve the interim remedial goals. Geochemistry results indicated that conditions favorable for reductive dechlorination were quickly established with dissolved oxygen (DO) levels reduced from about 6-μg/L to <0.5-μg/L and oxidation reduction potential (ORP) decreased from >100-mV to around -100-mV. Within four months post-injection, TCE concentrations within the source area decreased from approximately 1,600-μg/L to <10-μg/L.

Based on success of the source area treatment, site-wide treatment was conducted. For less than $650,000 and only six months after injection and distribution of the emulsion throughout the aquifer, TCE concentrations were reduced by over 99.9% to < 1 μg/L. The Army has since transferred the property and the new owner is redeveloping the site for commercial/retail use.

Permeable Reactive Biobarrier

At the second site, Solutions-IES demonstrated the use of emulsified oils for treatment of perchlorate and chlorinated solvent-impacted groundwater under the DOD’s Environmental Security Technology Certification Program (ESTCP), which “promotes innovative, cost-effective environmental technologies through demonstration and validation at DOD sites.” The consultant selected a rocket manufacturing facility in Maryland with a co-mingled perchlorate and 1,1,1-trichloroethane (1,1,1- TCA) plume for the ESTCP demonstration.

A groundwater pump-and-treat system was put in place at the Maryland site. The system consisted of an extraction trench, air stripper and infiltration gallery. Pump-andtreat systems typically require long operational lives (20 to 30 years or more) to achieve groundwater standards. Furthermore, while air stripping is an effective technology for removing chlorinated solvents, it isn’t effective for perchlorate.

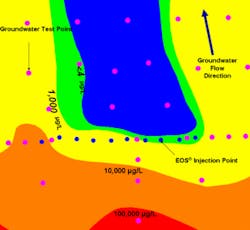

A field pilot test was conducted to evaluate the effectiveness of the emulsified oil formula for remediating perchlorate and 1,1,1-TCA in a barrier configuration. The shallow aquifer, consisting of silty sand and gravel to a depth of 15-ft bgs, was targeted for treatment. This aquifer was impacted by a former lagoon that had received ammonium perchlorate and waste solvent. Perchlorate concentrations in the groundwater ranged from 5-150 mg/L, and 1,1,1-TCA concentrations were 5-20 mg/L. Groundwater flow velocity at the site was calculated to be between 50-ft and 100-ft per year.

The field pilot test consisted of injecting emulsion into a row of injection wells oriented perpendicular to groundwater flow to intercept the contaminant flow paths. About 840 lbs of the substrate were injected to create a 50-ft-long permeable reactive barrier. Groundwater monitoring was conducted before and after injection to evaluate changes in aquifer geochemistry and contaminant concentrations. Geochemistry results indicate anaerobic reducing conditions were quickly established in the injection zone. Sulfate and nitrate concentrations decreased, while dissolved iron and manganese increased. Methane was also produced in the injection wells, and ORP levels in the groundwater were reduced to less than -50-mV.

With such favorable conditions for anaerobic degradation, EOS injection resulted in immediate and substantial reductions of the target contaminants. Within five days of injection, perchlorate concentrations were reduced from an average pre-injection concentration of 9,700 μg/L to less than the detection limit of 4 μg/L in the injection wells and monitor wells 10-ft downgradient. The expanded impact of the barrier and longevity of the effect were recognized by six months post-injection, when perchlorate concentrations 35-ft downgradient of the barrier also were below the detection limit of 4 μg/L. The emulsified-oil biobarrier continued to be effective in degrading perchlorate one year after injection.

The biobarrier also successfully degraded 1,1,1-TCA. Passage of contaminated groundwater through the barrier resulted in 90-98% reductions in 1,1,1-TCA concentrations more than 20-ft downgradient of the barrier. Production of 1,1-dichloroethane (1,1-DCA) and chloroethane (CA), the breakdown products of 1,1,1-TCA, were observed in the injection and downgradient wells confirming degradation of the parent compound.

Conclusion

The EOS remediations at the TAMP facility and the Maryland ESTCP site demonstrate the effectiveness and versatility of this simple, yet powerful technology. Based on successes achieved, plans to expand these projects were considered at both sites. Replacing the existing air sparging and pump-and-treat systems already in place with an expanded remedial effort using EOS have provided both sites’ environmental managers with substantial cost savings over the life of the project.

Author’s Note:

Christie Zawtocki is a former senior engineer at EOS Remediation Inc. of Raleigh, North Carolina, USA, a leading, U.S.-based bioremediation company supporting projects worldwide. The above article was updated from a version in the October 2005 issue of Military Engineer, a publication of the Society of American Military Engineers. Contact: 919-873-2204, [email protected] or www.eosremediation.com