By Brad Marchant

Canada’s BioteQ Environmental Technologies is applying its water treatment technologies for recovery of gold at the Lluvia de Oro mine site in northern Mexico with Columbia Metals.

How do you convert water into gold? If you think it’s not possible, think again. BioteQ Environmental Technologies is applying its biogenic sulphide technologies, used successfully in commercial operations for water treatment and metal recovery, to extract copper from cyanide solution and recycle cyanide for use in gold extraction at the Lluvia de Oro mine site in Sonora, Mexico – in essence, using its wastewater treatment technologies to allow for recovery of gold.

Many of the known gold deposits in the world are in areas rich with copper. For gold miners, this creates a challenge because copper is soluble in cyanide, the chemical used to leach gold from the ore body. Presence of leachable copper in a gold ore body results in low gold recovery, and can increase cyanide consumption, increasing gold extraction costs and environmental risk. In some cases, it can cause the gold leaching process to grind to a chemical halt. As a result, many gold ores aren’t being mined, or were abandoned after the start of operations, due to metallurgical challenges and high cost of treating cyanide-soluble copper minerals in the ore.

But with the rising price of gold (trading of late at around US$875 an ounce – over double that of four years ago, but down from it’s 52-week high of US$1,012.60 on March 18), and the general scarcity of this precious metal, mining companies are looking for innovative ways to recover gold from deposits previously considered marginal. One of them is Columbia Metals, the owners of the Lluvia de Oro and La Jojoba mines sites in northern Mexico.

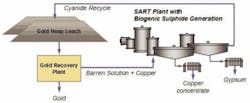

BioteQ is applying its biogenic sulphide technology, originally developed to treat metal-contaminated water, to remove copper from cyanide solution, and re-generate the cyanide for gold recovery at the Lluvia de Oro mine. The company adapted the SART process (Sulphidization-Acidification-Recycle-Thickening) originally developed by SGS Lakefield and TeckCominco Ltd. BioteQ’s innovation is to use its patented BioSulphide® process to produce low-cost biogenic hydrogen sulphide (H2S), replacing the chemical sulphide traditionally used in the SART process. Its technology has the added advantage of lowering acid demand by a third for copper cyanide treatment and by half for zinc cyanide. And it allows for recovery of a saleable copper product, which helps to offset treatment costs.

In effect, this process changes the economics of gold mining sites that may once have been considered marginal because of the presence of base metals, such as copper and zinc, in the ore body. And because the process reduces overall cyanide consumption, it can reduce the environmental impact of the gold mining process.

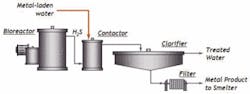

The biogenic sulphide process, originally developed to remove dissolved metals from contaminated water, has both a biological and a chemical stage. In the biological stage, sulphur-reducing bacteria in an anaerobic bioreactor produce H2S gas. The gas is transferred to a contactor tank that contains the contaminated water to be treated; in the chemical stage, the tank’s solution chemistry is adjusted to selectively precipitate metals as pure metal sulphides. The precipitated metals and treated water are pumped to a clarifier tank where clean water is separated from the metal solids and discharged or recycled. Metal solids are filtered to remove excess water, producing a high grade metal product suitable for refining. To recover multiple types of metals, separate contactor and clarifier tanks are set up in series. The outputs are saleable metal products and clean water that can be discharged to the environment.

BioteQ’s water treatment roots are in the mining industry, where it finances, builds, owns and operates water treatment plants that remove toxic heavy metals from acidic waste water produced through process streams or through the natural process of acid mine drainage. The company’s technology enables customers to reduce the environmental liability associated with metal contaminated water while generating revenue from waste. In addition to its sulphide technologies, the company has developed a new ion exchange technology to remove sulphate. It has successfully built and operated four water treatment plants in Canada and the United States, and is presently constructing six new plants in China, Australia, Mexico, and the United States. Customers include Xstrata Nickel, Aditya Birla, Jiangxi Copper, Vale Inco and the U.S. Environmental Protection Agency.

The construction of BioteQ’s first commercial scale SART plant which will use biogenically produced sulphide reagent is currently in progress in Mexico at the Lluvia de Oro mine for Columbia Metals. The plant was scheduled for commissioning in the second quarter of 2008, and will recover copper and cyanide from solution and recycle cyanide for use in gold extraction. This is a build, own, operate project where BioteQ is putting up the capital for the plant in exchange for the copper recovered and a processing fee for recovery of cyanide. Use of the same technology for Columbia’s La Jojoba property is planned for 2009.

So water can be turned into gold. No alchemy involved – just innovative science and water treatment know-how.

Author’s Note:

Brad Marchant is the CEO of BioteQ Environmental Technologies Inc., of Vancouver, Canada. He is a specialist in mineral processing and biohydrometallurgy, and has 25 years of experience in plant operations, process consulting, business development and management, working in the mining industry around the world. Contact: 604-685-1243 or www.bioteq.ca