By Daniela Hornung

UV light helps ensure safe bathing in a German river by killing bacteria in Bavarian clarification plants before discharge during summer months

In addition to conventional processes for cleaning water – such as use of chemicals like chlorine and ozone or filtration systems – the importance of ultraviolet (UV) light as a reliable, environmentally friendly and economically viable alternative continues to grow.

Community wastewater, after being cleaned in clarification plants, is reintroduced into the water cycle via rivers, lakes and coastal waters. Special treatment is necessary if, at subsequent points, drinking water is extracted or wastewater is fed back to bathing waters. If the wastewater has a high germ count then the hygienic conditions for bathing becomes doubtful as there are significant dangers of infection for humans.

Project ‘Clean Isar’

The city of Munich and state of Bavaria started a project to improve the hygienic water quality of the river Isar and ensure safe bathing during the summer months. One part of the Isar is diverted into the Isar canal and used for hydropower. The remaining Isar between the cities of Bad Toelz and Freising carries very little water as a result. By introducing treated wastewater from the clarification plants in this area, the degree of contamination was high. In spite of sufficient treatment, the water was heavy with pathogens.

The Europe-wide, unique “Clean Isar” project included the decision to use UV disinfection as the final cleaning stage in the sewage treatment plants which fed the wastewater back into the river. The aim was to significantly reduce the germ count of the wastewaters and so improve the hygienic water quality of the Isar in the bathing season, while meeting severe EU bathing water regulations. In 2000, Bavaria showed evidence from the pilot scheme for wastewater disinfection in Bad Toelz that bathing water quality could be achieved in the Isar. Of concern are bacteria and viruses that play an important role in illnesses in bathers, particularly fecal germs, streptococci, salmonella and enteric viruses.

Disinfection without Chemicals

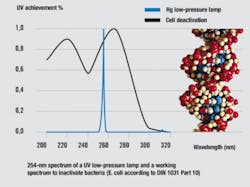

Treatment of water with UV radiation is an effective physical process for reliably disinfecting water and breaking down pollutants when appropriately applied under the right conditions. At wavelengths of about 254 nanometers (nm), UV rays are absorbed by the DNA and destroy its structure, either killing microorganisms outright or preventing their ability to replicate.

Thus, with effective pretreatment to reduce shadowing effects and proper flow and dosage, UV inactivates waterborne pathogens such as bacteria, viruses, fungi or parasites in a matter of seconds. In addition, chlorine-resistant parasites such as Giardia and Cryptosporidium can be killed by UV light. An important benefit is that this cleaning process takes place completely without chemicals and, hence, there are no chemical residuals or disinfection by-products.

UV light is versatile in its application – it can be used to treat water, air and surfaces. Drinking water treatment in waterworks, wastewater treatment in sewage treatment plants or process water treatment in industry (typically, the recycling and reuse of process water) are the interesting applications of UV in the water industry.

Growing Acceptance

The physical method of disinfection with UVC light is a reliable and economical technique that’s often used for the disinfection of water. For example, New York City has chosen this technology for drinking water disinfection for new waterworks planned for the Catskill/Delaware catchment area about 160km north of the city. This will be the largest UV disinfection plant for drinking water in the world. Beginning in 2010, the new waterworks will treat up to 2.2 billion gallons (8.3 million cubic meters) of water per day for more than nine million people in New York City and its environs.

In recent years, the acceptance of UV disinfection in commercial applications has continued to grow. It has been successfully used for wastewater treatment in the USA for decades and is now becoming increasingly specified in Europe – as in the Isar project.

The town of Freising also has settled for sewage disinfection via UV irradiation to provide hygienic wastewater and clean water in the Isar. Its wastewater treatment plant (WWTP) treats about 5 million m³ from the town, its commercial companies (dairy, breweries) and eight neighbouring townships.

Within the scope of the “Clean Isar” project, the Freising plant was completely modernised and enlarged. Today, the clarification plant is designed for an 110,000 inhabitant value. The plant expansion includes a new biological treatment plant, settling tanks, a fish pond, new combined heat and power (CHP) plants and a UV disinfection plant.

Freising decided upon UV systems from the Canadian manufacturer Trojan Technologies. These were installed in September 2005 and began operation in summer 2006. An important plus point was the sophisticated wiper techology of the TrojanUV3000Plus system, which continuously removes any dirt or deposits from the quartz safety tubes. This possible coating, which is often ferrous, leads to a reduction in the UV intensity in the water.

The UV plant in Freising is fitted with 196 UV lamps, each of 250W output. The lamps are contained in UV-transparent quartz glass tubes that are tightly sealed. Two open channels work with two corresponding banks, which are each fitted with six modules. The plant is self-regulated according to the wastewater throughput. Depending on that throughput and the water transmission, one channel is operated with the necessary number of modules. The lamp power can be controlled between 60% and 100% intensity. An SPS controller automatically regulated the operating mode. A UV sensor continually monitors lamp intensity and an on-line measurement of water transmission matches the power to the demand.

The Freising plant is designed for a maximum of 652 liters per second (2,350 m³/hour). Maximum input is 611 lps. This ensures that the capacity of the UV plant is sufficient to handle the maximum expected wastewater input. The plant delivers a UV dose of 306 Joule/m², which ensure certain UV disinfection.

An external, independent laboratory takes monthly samples and tests the water quality. The samples are taken before and after the UV plant and look out for fecal germs and streptococci. The regional authority also monitors the wastewater quality. This takes the form of unannounced, monthly sampling to check bathing water quality.

Freising sewage works manager Willi Frankl says of his experiences: “The plant stands or falls on the UV lamps. The operating life of the lamps is a decisive factor. The later I have to change over lamps, the more economical the UV plant.”

The energy efficiency of the UV disinfection plants in communal clarification plants can be improved by using particularly efficient UV lamps. The challenger for today’s UV lamps is to significantly increase their efficiency and operating life.

Different Lamp Technologies

Water disinfection can involve use of compact medium-pressure UV lamps, low-pressure UV lamps and high power amalgam lamps.

Medium-pressure lamps give a broad band spectrum over the complete range from 200nm to 400nm. Their high radiation flux allows very good disinfection from compact units. Similarly, with high throughput, it’s possible to design very compact disinfection systems. For example, these lamps are used onboard ships where space is limited to disinfect ballast water. Typical lamp operating life is 1,500 to 5,000 hours.

Low-pressure lamps emit radiation at a wavelength of 254nm. Classical UV low-pressure lamps offer exceptional efficiency: up to 40% of electrical power is converted into UV radiation for disinfection. Still, the power density is limited and a large number of lamps is often required. When synthetic quartz glass is used as the lamp material, additional UV irradiation at 185nm is emitted, which can be used for oxidation processes. The first lamp change is normally after 8,000 hours. After this, the lamps exhibit a dropoff in UV intensity of up to 50%.

There are, however, significantly longer life lamps. For example, the specialist light source manufacturer Heraeus Noblelight has developed new high-power, amalgam lamps that operate for up to 16,000 hours with virtually constant UV output and so provide significantly more power than conventional standard low-pressure lamps, with their usual operating life of 8,000 hours. At this point with conventional UV lamps, mercury (Hg) diffuses into the quartz, so that such lamps deliver only 50% of their original UV power. A unique long-life coating doubles the life of amalgam lamps. This new technology not only improves the useful life of the lamps but also ensures a virtually constant UV output over the length of this working life.

In comparison with previous UV lamp technology, amalgam lamps offer the best combination of efficiency and operating life. Thanks to the higher UV output and long operating life, system builders now need fewer lamps in any new disinfection plants they design. As a result, there’s significant potential for savings in the number of lamps, system components, energy demands and, maintenance and service costs. End users, such as waterworks and clarification plants, profit from the long operating life. The time between lamp changes is virtually doubled while the operating time provides the lamps with more UV power than conventional low-pressure lamps.

New Applications

The increasing environmental pollution caused by medications in wastewater is becoming more of a problem. In order to destroy the very complex pharmaceuticals such as steroids and antibiotics, it’s sensible and effective to use a combination of UV radiation and powerful oxidation substances such as hydrogen peroxide. UV radiation at a wavelength of 185 nm makes even higher energies available and allows oxidization processes, which can break down health-threatening chemicals in water.

WWi

Author’s Note:

Daniela Hornung is marketing project manager at Hanau, Germany-based Heraeus Noblelight GmbH. The company, which develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, and analytical laboratories, has subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico. Contact: [email protected] or www.heraeus-noblelight.com