The presence of clean water for animals' well being is often taken for granted by zoo visitors. Low pressure, high power amalgam lamps are being developed and proving that modern UV technology is disinfecting water in zoos and aquaria without the addition of chemicals. Thomas Lödel looks at the processes involved and Copenhagen installations.

A visit to the zoo is a well-loved leisure activity for both young and old. Many zoo animals either live in water or water is an important element of their natural environment, such as elephants, crocodiles or hippopotami. Consequently, water quality is critical to the animals' well-being. Water treatment takes place in the background, unnoticed by the visitors to the zoo, and a look behind the scenes into this important activity is very worthwhile.

Animal-friendly water treatment with UV Technology

Take Copenhagen Zoo in Denmark. Every year more than 1.3 million people visit the zoo, which is home to around 250 animal species and more than 3,300 individual animals. One example of water sources in need of treatment is the 600m³ fresh water area (inside and outside pool) for hippopotami. Furthermore, the Odense Zoo, also in Denmark, includes a seawater pool system for manatees and penguins, which has a flow rate of 6 m³/h while the Randers Rainforest includes water treatment systems for manatees, crocodiles and aquaria e.g. an inside crocodile pool with a circulation capacity of 30 m³/h.

So how is UV technology used for water disinfection in such examples? By using high energy UV radiation at a wavelength of 200-280 nm (UV-C) bacteria, fungi and viruses can be effectively destroyed (Fig.2).

All these micro-organisms contain, among other things, the nucleic acids (DNA and RNA), which contain the genetic information of the cells. The nucleic acids absorb the UV radiation and a photochemical process is initiated, which destroys the reproductive apparatus of the micro-organisms and kills the germs, with the result that the pathogens die off (Fig. 3).

Water disinfection using UV radiation offers a number of benefits: micro-organisms are unable to build up resistance; there are no disinfection by-products; the process is entirely free of chemicals so that there is no effect on water composition, smell or taste.

As well as reducing the danger of illness, the above points are also very important for the zoo inhabitants, as they affect the way that the animals accept their living conditions and considerations such as stress, eating habits, growth, life expectancy and birth rate. Furthermore, at around 0.01Euro/m³, UV light is the most cost-effective, non-chemical water disinfection technique.

The killer blow

The "killer" UV dose, the so-called lethal dose is known for nearly all micro-organisms. Principally, it depends on the cell structure of the pathogen. Consequently, bacteria are more receptive to UV than fungi, which because of their stable cell walls with pigments require a higher lethal dose.

For example, for a disinfection rate of 99.9%, a lethal dose of 9.0 mWs/cm² is required for Coli bacteria, while for the mould fungus Aspergillus Niger it is around 396 mWs/cm². In addition, the required UV dose is also affected by diverse physical parameters in the water such as transmission, suspended solids and iron content.

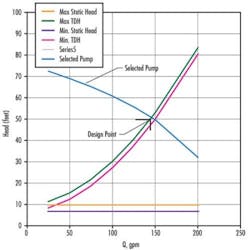

Water is mainly disinfected using the flow through technique in UV water reactors. The systems offer flow rates of 30 to 700 m³/h and several reactors can be connected in series or parallel.

According to the type and capacity of the system, in the reactor cylinder there can be up to twenty two 220 W UV low pressure amalgam lamps or up to fourteen 440 W UV low pressure high power amalgam lamps from the specialist light source manufacturer Heraeus Noblelight (Fig. 4).

Their quasi-monochromatic spectrum of 254 nm is ideal for effectively disinfecting water. A special technique provides for a continuous rotation of the water in the cylinder to prevent the deposition of fine particles on the UV lamp tubes. As a result, water with a high concentration of suspended solids above 10 mg/l can be treated.

The process has been used for many years in the treatment of drinking water and is supported by national standards in many European countries as well as in the USA, Canada, Japan, etc.

The role of low pressure, high power amalgam lamps

Conventional low pressure lamps usually have an operating life of around 8,000 hours. Compared with conventional UV low pressure lamps, the newly-developed 440 W high power amalgam lamps from Heraeus Noblelight have a Longlife coating.

During operation, mercury ions are implanted in the top layer of the SiO2 matrix of the quartz tube of the lamp, where they form mercury oxide.

This creates increasing transmission losses in the quartz tube of the UV lamp and this diminishes the emission of the UV radiation. In fact, a layer of mercury oxide just a few nanometres thick reduces the transmission by 50% and more (Fig. 5).

Consequently, conventional low pressure lamps usually deliver only around 50% of their original UV power at the end of their operating lives.

The high power amalgam lamps with the Longlife coating on the other hand offer a significantly longer operating life of 12,000 to 16,000 hours at virtually constant UV output power (up to 90% after 16,000 hours.).

Consequently, this type of lamp provides much more power output over its operating life than conventional UV low pressure lamps and offers the best combination in terms of efficiency and useful life.

System builders need fewer lamps in the design of water treatment lamps. This provides significant potential for savings, in number of lamps, system components, energy consumption and service costs.

End users, such as zoos, benefit from the long operating lives and extended service intervals. Up time and time between lamp replacements are significantly extended, while the lamps provide more operational UV output than conventional low pressure lamps.

Author's note: Thomas Lödel, industrial engineer, is the head of marketing at Heraeus Noblelight GmbH, headquartered in Hanau, Germany. More information can be found at: www.heraeus-noblelight.com.

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles