The Awali-Beirut Water Conveyance project aims to provide secure and safe water supply from southern Lebanon to the developing urban areas of Beirut. Sudhir Kumar, technical leader of the project, discusses latest developments of the tunnel development, including key considerations such as exposure to seismic activity and security concerns.

The feasibility report update ensured the treatment facility will meet drinking water guidelines issued by WHO

The Middle East and North Africa (MENA) is the most water scarce region of the world and in recent years the amount of water available per person has declined dramatically.

Lebanon, in contrast to neighbouring countries to the south and east, has adequate total water resources but at present lacks a conveyance system to deliver water to locations where it is most needed. Its capital, Beirut, currently suffers a severe shortage of water, a situation which was foreseen before the civil war in the 1970s.

Project DetailsThe Council of Development and Reconstruction (CDR) has engaged MWH to update the feasibility study of Awali-Beirut Water Conveyance project, which was carried out in 1994, and to prepare tender documents. The main focus of the feasibility study update is to analyse the differences between the situation in 1994 and at present. This is also to review the option of water conveyance through tunnels, which were identified in the 1994 study as the preferred option.

Current potable water demand in the main city of Beirut area is estimated at 780 million litres per day (780,000 m3/day) for a population of over two million. In the driest month of October, Beirut can experience a deficit of 368 MLD (368,000 m3/day). As a result, water supply in many parts of Beirut is intermittent. Furthermore, reliance on wells coupled with the effects of salinity ingress has resulted in many homes being supplied unpalatable water along coastal areas.

Awali- Beirut Water Conveyance Project

The current major water supply source for Beirut is from Dbayeh in the north. The Awali Beirut Water Conveyance Project was originally envisaged in the 1950s to make use of abundant water resources provided by the Litani and Awali Rivers in the south of Beirut.

The construction of the Qara'aoun Dam on the Litani River made water available for irrigation, water supply and hydroelectric power generation. In practice, only the last of these uses has come to fruition so far.

A series of tunnels takes water from the Qara'aoun Dam through the mountains to the Awali River via two hydroelectric power (HEP) stations. A final tunnel conveys water from both the rivers to a third HEP station, which discharges back into the Awali River. A Government Decree was issued in 1970 for the diversion of water from the final stage of the HEP system to supplement the existing water supplies in Beirut.

The objective of the Awali Beirut scheme is to provide a secure and safe water supply from southern Lebanon to the developing urban areas of Beirut. The scheme includes treatment and transmission of 520 MLD (52,000 m3/day) water in two phases with the possibility of expansion to 780 MLD (78,000 m3/day). Phase I will treat and transmit only 260 MLD (260,000 m3/day), which will go some way in meeting the current deficit. Essential components of the selected scheme are:

• Abstraction of water from the existing HEP tunnel at Joun (south of Beirut) and delivery to the treatment plant at Ouardaniye by 4 km long, 2800mm diameter tunnel

• Treatment to accepted potable water standards at Ouardaniye

• Transmission of treated water from Ouardaniye to the Khalde by a 20km long, 2800mm diameter tunnel

• Transmission of treated water from Khalde tunnel outlet to number of new reservoirs located in South Beirut by transmission pipelines with total length of 30km, including diameters of between 1000mm to 1400mm. The whole scheme is designed under gravity flow by taking advantage of the available hydraulic head between extraction and delivery points.

Feasibility study options

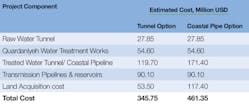

The abstraction and delivery points of the project are 40km apart with highly varying topography characterised by hills and steep valleys. Two feasible options - namely water tunnels and coastal pipelines - were explored for the transmission of water from Joun to Khalde.

The coastal pipeline option shares a few critical technical challenges, including:

• Security concerns as a result of an exposed rural pipeline, which would be very vulnerable to tampering and intentional acts of damage or foreign aggression

• Exposure to damage from seismic activity because the pipe route runs through a seismically active zone

• High pressure of the pipelines (+25 bar rating requirement) due to elevation differences could result in very severe consequences if a pipe was to burst. Any failure in one pipe could damage the adjacent pipe (of the twin pipes), causing complete cessation of service. Pipe failure would also threaten local infrastructure, including the coastal freeway and adjacent properties and endanger residents

• Extensive expropriations and service corridor requirements particularly given strong urban development especially towards the end of the pipe route

• Major service crossing (bridges, underpass, culverts, utility pipelines) issues along the pipe alignment, and aesthetic and environmental implications due to the extensive construction through rural and natural areas.

In light of the listed challenges, a tunnel option was deemed technically superior due to its low susceptibility to such raised concerns. High pressure operation inherent in piped options, the vulnerability of exposed infrastructure, nature of the locality and characteristics of pipe materials were all taken into consideration.

The scheme includes treatment and transmission of 520,000m3/day

Furthermore, tunnelling though the hills allows the shortest route to the end point of the project. The tunnel also follows the hydraulic grade line with less design constraints, with the exception of deep valley crossings. Due to the minimum economical size of a tunnel, the tunnelled option also provides additional capacity for any future expansion, and some degree of storage within the tunnel space itself. Most importantly, the tunnelled solution has a significantly smaller surface disruption footprint.

The final and most compelling reason for selecting a tunnelled solution was that all options, whether piped or tunnelled, require the first stretch of the conveyor from Joun to Ouardaniyeh be tunnelled in order to access the Joun Adit.

Natural Ground Profile along Tunnel Alignment

Therefore by default, any solution selected will involve some tunnelling. A financial comparison of the two options shows that the coastal pipeline option is 33% more expensive than the tunnel alternative.

A detailed techno-economical analysis of these options suggested the tunnel option as the preferred one. The annual O&M cost for the Phase I work of tunnel option is USD 5.96 million (year 2010) which results in a treated water O&M rate of USD 0.06 per m³. The financial analysis of the project suggested that the project is financially viable at the cost and level of tariffs adopted and the project will pay back at the end of the 13th year.

Awali - Beirut Water Conveyance project components

The Awali-Beirut scheme is divided into three contract packages. Package one covers 2800mm internal diameter x 24 kilometres of water tunnels. The first phase of the 260 MLD (26,000 m3/day) water treatment works will be covered in Package two, and finally 30 kilometres of water pipelines and service reservoirs will be covered in Package Three.

Package one - water tunnels

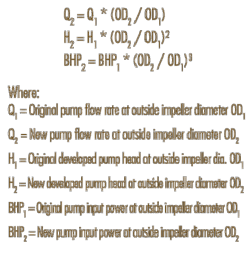

The main factors governing the excavation costs of a tunnel are its diameter, length of the drive and the speed at which the Tunnel Boring Machine (TBM) face can be advanced. The typical relationship between costs and the tunnel diameter shows that the most economical diameter is between three and five metres.

Considering the common TBM availability and the construction issues - removal of excavated material, service piping and in-situ tunnel lining - a 2.8m internal diameter was selected for the project.

Such a selected diameter can hydraulically carry up to 780 MLD (78,000 m3/day) of water, which is significantly higher than the Phase 1 & 2 requirement of total 520 MLD (520,000 m3/day) and provides a contingency for possible increased water demand in future.

Soil strata to be penetrated by the tunnels are Cenomanian- Turonian limestones, dolomitic limestones and dolomites. The tunnel will be concrete lined by in-situ construction method. Additional steel lining is provided along the geologically weaker sections of the tunnel alignment, or where the depth of cover over tunnel is inadequate.

Package two - water treatment works

The location of the proposed water treatment works at Ouardaniyeh has been selected considering the hydraulic advantage, lower cost of land and an opportunity to include take offs to the coastal town along the tunnel route.

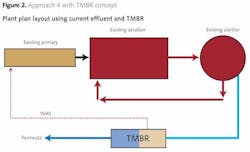

As part of the update to the 1994 feasibility report, the proposed treatment process has been reevaluated. The major goal was to assess its ability for fulfilling the latest drinking water guidelines and standards issued by the European Council and also the World Health Organisation.

Variable raw water quality, as a result of seasonal changes, has been taken into account to provide a process scheme capable of treating two different raw water characters to the desired effluent quality. The proposal will be constructed in two phases, each designed for 260MLD (260,000 m3/day) capacity.

Package three - transmission pipelines and reservoirs

Approximately 30km of transmission pipelines with diameters ranging from 1000mm to 1400mm are being proposed to transfer treated water from the tunnel outlet portal at Khalde to the five service reservoirs at Hadath and Hazmeih, including a total capacity of 155 ML (155,000m3/day) capacity.

MWH has already prepared the tender documents for Package one and two and the pre-qualification procedure for both the packages is expected to start in the first quarter of year 2011. The project is scheduled to be completed in three years. To help involve local contractors, a procurement mode for the third package is being considered, as well as a conventional consultant design and contractor build mode.

The company is waiting for CDR approval to proceed with detailed design of this package. The latter has realised the importance of this project and is working closely with the World Bank to fulfil the long awaited dreams of residents in Beirut.

The project will be an example of how neighbouring nations facing water shortages can work together and overcome substantial challenges to help deliver supply.

Author's note: Sudhir Kumar is a principal civil engineer and engineering group manager at MWH UK in Dubai and is working as technical leader on the project.

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles