Nifty Nanofiltration New Developments Show Promise

It has taken years for nanofiltration membranes to shake off negative connotations from the days when they were misnamed as failed reverse osmosis technology. Dr Graeme K Pearce discusses the latest technology developments and installations, including ceramic membranes varying from single hollow fibers to multi-bore monoliths.

There has been a dramatic evolution in the application of membranes in water and wastewater treatment during the last 30 years. The early 1980's saw the introduction of the thin film composite (TFC) membrane for reverse osmosis (RO). This was followed a few years later by developments in ultrafiltration (UF) and microfiltration (MF) that enable these membranes to be applied for large scale drinking water treatment.

The membrane research community expected nanofiltration (NF) to undergo similar radical change. The need for this technology appeared to be as compelling as for the other membranes. However, the very success of first RO, then of UF/MF drew attention away from the potential opportunity for NF.

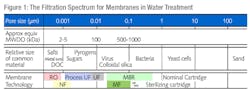

Figure 1 shows the filtration spectrum for filtration technologies in the water industry. RO removes dissolved salts, while UF and MF remove fine particles. However, the critical application of the removal of dissolved organic carbon (DOC) is not well addressed. UF/MF does not remove dissolved organics unless combined with coagulation. Even then, removal efficiency is not that high and any specific target molecules are likely to require further treatment to meet water quality targets.

RO membranes are fine enough to retain organics. However, the energy cost of RO is high due to the simultaneous retention of salt. This gives RO high operating costs since water transport across the membrane has to overcome the osmotic pressure as salinity increases on the concentrate side. Unless salt removal is the primary goal - one example would be for a seawater feed or a brackish water source - then RO is likely to be too energy intensive for general water treatment purposes.

NF offers the promise of removing organics without a significant reduction of ionic species, thereby meeting important water quality targets that are developing in the water industry.

Drivers

In broad terms, the driver for RO has been the need to develop alternative water supplies by removing a wide range of contaminants from impaired water sources. In contrast, the primary driver for UF/MF has been to meet newly introduced drinking water quality legislation.

There has been a need for additional water resources in arid areas such as the Middle East for some decades. More recently, this pressure has increased due to a gradual coastal migration, with populations tending to move towards warmer drier climates often near the coast. Seawater desalination using RO has been a primary solution to this requirement and the market has been growing at a compound growth rate of 17% pa for more than a decade [1].

Drivers for UF/MF have been developed to provide a disinfection barrier. The targets have focused on the removal of small particles including viruses, bacteria and protozoan parasites such as cryptosporidium and giardia [2].

However, for several years there has been an increasing concern with dissolved organics such as pesticides, agricultural residuals and pharmaceuticals. So far legislation has not been systematically introduced to address these contaminants but the Environmental Protection Agency (EPA) in the U.S. and the European Union have undertaken comprehensive reviews of the problem and potential solutions.

Currently, ozone is used in an Advanced Oxidation Process (AOP), potentially in combination with granular activated Carbon (GAC), to reduce pesticides. Also, UV can be used. However, the target molecules are now smaller and more stable than the original compounds of interest making the challenge for destruction and/or removal even greater.

Historical review and current status of NF

In the early days of RO development, Quality Control (QC) failures were sold at reduced prices and in some cases these elements were referred to as NF. This did a great disservice to NF from which it has taken years to recover. These QC rejects from RO did not perform at all like NF is supposed to, since monovalent salt rejection was far too high.

Specific products were developed for NF in the 1990's based on an open TCF membrane in a spiral wound element like RO. These products have been very successfully employed in the oil and gas sector. The application here is for the rejection of divalent ions, particularly barium and sulphate, from injection water for offshore oil wells. The fact that monovalent ion rejection with these membranes was also quite high did not matter in this application.

The important targets of divalent ion removal needed to be achieved with high efficiency. By 2000, NF spiral development received a boost with the introduction of products designed to remove organics without reducing the inorganic ion concentration too much. Some of these products used the original TFC chemistry while others use different polymers, such as cellulose acetate and polyethersulfone. They have been quite widely applied in the North American municipal water industry in Florida, the Pacific coast and Canada for the removal of compounds responsible for colour. They have also been used outside America in Scotland and Scandinavia.

A critical issue for water treatment is energy cost and this is becoming more important with the development of alternative sources. Energy costs of traditional fresh water sources are generally very low. At the opposite end of the spectrum, the energy cost of desalination is up to ten times as high and can only be justified on energy terms where the alternative is to transfer the water from far away, as can be seen in the State Water Project in California.

Wastewater offers promise as a lower cost resource but this too is fairly energy intensive due to aeration requirements. Current NF spirals use less energy than wastewater reuse schemes but are significantly

NF product developments

The problem with spirals is that they require excellent feed quality to avoid fouling. Thus the NF stage is effectively added on to existing treatment. A new range of NF products target the removal of organic molecules but minimise the rejection of inorganics. By doing so, they

offer the promise of lower pressure operation. However, high organic rejection means that it is important that the membrane is low fouling since at high recovery, the concentration of organics in the feed stream will rise sharply. Another feature of these new product developments is that they do not use a spiral format, thereby reducing the need for pre-treatment.

The first NF product reviewed here has been launched recently from Pentair-Xflow (formerly Norit) and is based on a hollow fibre format. This product is based on the same PES fibre used for UF but with a molecular weight cut-off < 1.8 kDa, providing a rejection of 75% UV 254 organic compounds. The product is commercially available and is being used on demonstration scale. The great advantage of hollow fibre compared to spiral wound is the elimination of any significant pre-treatment, as solids introduced into the feed channel during the filtration cycle are efficiently displaced during backwash or flushing.

A different approach has been taken by DXV, a new start up in the US. The firm's product is based on a low fouling flat sheet format. The module does not use a spacer between the sheets and relies on cross flow circulation to keep the channels clean. DXV has reached the stage of pilot operation and has focused on wastewater polishing using a single membrane treatment stage, with infrequent chemical cleaning. Pilots have shown that the chemical cleaning requirement for the RO stage can potentially be eliminated or at least significantly reduced.

Another U.S. start up with an interesting NF membrane technology is Clean Membranes Inc. This early stage start up is commercialising technology developed at MIT (Massachusetts Institute of Technology). The grafted co-polymer membrane is a modified highly hydrophilic polyacrylonitrile (PAN) membrane which can be produced at pore sizes from NF to fine UF.

The final company in this brief review is the German company ItN, which is commercialising a range of ceramic membranes, as shown in figure 3. The products vary from singe hollow fibres to multi-bore monoliths. A wide range of pore size cut-offs is claimed extending down to the NF part of the spectrum, which is unusual among commercial ceramic products. ItN recently announced a commercial installation in Saudi Arabia pre-treating a highly brackish well water in place of conventional or UF/MF pre-treatment. The NF pre-treatment is claimed to allow 20% higher RO throughput.

Moving forward

Nanofiltration has been an overlooked technology in the membrane separations spectrum. NF spirals have been introduced into water and wastewater applications for some time but they are dependent on extensive pre-treatment. Existing NF products targeting organic molecule removal also tend to remove salts making energy use high.

These products promise improved energy efficiency since they all feature low fouling membranes with limited salt rejection. Equally important, they use module formats that do not require pre-treatment. WWi

References

[1] T Pankratz, SWRO market exceeds Forecast, Water Desalination Report, Vol 44/ no. 22, 21st June 2008, p1

[2] G K Pearce, UF/MF Membrane Water Treatment, publ Water Treatment Academy, Thailand, in press, Jul 2011

[3] C Ventresque et al, An outstanding feat of modem technology: the Mery-sur-Oise Nanofiltration Treatment Plant (340,000 ml/d), Desalination 13 1 (2000) 1-16

[4] G K Pearce, UF/MF pre-treatment to RO in Seawater and Wastewater Reuse Applications: A Comparison of Energy Costs, Desalination, 222 (2008) 66-73

[5] Import or Desalinate, Water Desalination Report, p2-3, 25th June 2007

Author's note:Dr Graeme K Pearce is a membrane technologies specialist with 25 years experience in the industry. He is principal at Membrane Consultancy Associates. Email: [email protected]

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles