Winds of Change for Reverse Osmosis Seawater Desalination?

Membrane desalination capacity is growing globally but so is its demand for power, usually supplied through fossil fuels. With renewable energy sources such as wind power being proven, are there opportunities to combine the two? Joachim Käufler, Robert Pohl and Hadi Sader discuss the practical and economical feasibility of wind powered seawater reverse osmosis.

Energy consumption of industrial scale seawater desalination has decreased significantly over the past few decades. Advantages in membrane technology and energy recovery devices have led to a relatively low specific energy consumption (SEC) of reverse osmosis (RO) processes to around 2 – 4 kWh/m³.

Lower energy consumption per unit, lower investment costs, a simple process control and a very flexible plant design have all helped RO to gain a significant market share within the field of small and large-scale desalination plants (< 100,000 m³ daily).

However, due to the ever expanding desalination market, total electric energy consumption of desalination, especially RO, will increase. With nearly all electric energy for commercial seawater reverse osmosis (SWRO) generated by fossil fuels, this presents challenges and concerns. This includes costs (energy can represent 30% to 60% of total water production (RO) costs), through to reliability. For example, if fossil fuel energy sources are supplied internationally, then reliability of supply could be affected negatively by political conflicts.

These concerns can be avoided or minimised by using locally available renewable energies, such as wind or solar power. And feasibility studies carried out could see wind powered RO desalination proven in Bahrain, in the Middle East.

In February 2011 a Memorandum of Understanding was signed between SYNLIFT Systems and Jade Consultancy to help develop the concept of wind powered seawater desalination. Extensive laboratory studies simulating Gulf region conditions suggest the concept is both technically and commercially available. The basis of which will be presented in the following article.

Why wind power?

As a freely accessible source, wind energy offers low and long-term stable power generation costs, as demonstrated in Table 1 below. Considering the steadily increasing grid tariffs, the direct consumption of wind power within a local sub-grid constellation is becoming the most beneficial option for an increasing number of sites.

Principles of seawater desalination

At an industrial scale, thermal as well as membrane processes are used for seawater desalination. The thermal desalination processes are characterised by the phase change of the seawater in which the product is separated by condensation of the vapour (see figure 2). Well-known applications of thermal desalination at industrial scale are the Multistage Flash Evaporation (MSF), the Multi Effect Distillation (MED) and the Mechanical or Thermal Vapour Compression (M/T VC).

Membrane processes operate without phase change. By regulation of the chemical potential across a semi-permeable membrane a partial flow of seawater is separated as permeate. Within industrial seawater desalination, RO is increasingly important. For desalination of brackish water with lower salinities the Electro Dialysis is as well applied.

Compared to other desalination principles, certain characteristics make RO more suitable for a wind powered desalination process compared to other desalination principles [1-4]. These include a high process dynamic – the ability to adjust the power of the desalination plant quickly in the event of fluctuating wind power.

Principle of RO-process for seawater desalination

RO is applied as cross-flow filtration and pressurised seawater with feed flow flowing along the semi-permeable membrane. If feed pressure exceeds the osmotic pressure of the seawater a fraction of water diffuses through the membrane and is collected as permeate flow (see figure 3).

The retentate flow is depressurised by the downstream energy recovery device. Recovered energy is transferred as hydrostatic pressure directly to an equal fraction of the feed flow or indirectly by boosting the high-pressure pump flow.

The power of the high-pressure pump could be adjusted continuously within a broad range of feed pressure and flow in order to adjust the permeate production to varying water demand and feed conditions or – relevant for WIP – to the fluctuating wind power generation.

Variable operation of RO-process

Since RO is applied for seawater desalination, the concept of powering the process with abundant wind energy potential can be introduced and developed further. Within the RO-community to date there lacks conclusive assessment of whether thin-film composite membrane material deteriorates when exposed to a long-lasting variable process. To date industrial RO-plants are operated with constant process parameters and membrane suppliers recommend uninterrupted operation at nominal capacity, in order to maximise the full cost of the membranes.

To reach a verifiable assessment, comparative long-term tests have been carried out by SYNLIFT Systems with variable and a constant operated membrane, respectively [5]. The performance deterioration due to compaction and reversible fouling – mainly affecting the RO-performance under constant operation – was investigated comparatively. For the variable operation, periodically altered process parameters were set in a way that at the beginning of the test run both membranes, which had the same feed power.

Altogether, in none of the test runs could a performance deterioration of the variable operated membranes compared to constant operated membranes be observed.

However, minor positive effects on membrane performance were encountered due to deactivation periods. External investigations derived similar conclusions [6].

System configuration

SYNWATER® modules together with integrated load and storage management permit an optimal direct use of the freely accessible and low-cost resource wind as process power. The surplus production and storage of potable water in strong wind periods and the complementary hybrid power supply (wind/grid) enable a safe and cost efficient water supply even in lull wind periods. Modules used are designed for medium (200 - 5,000 m3/day) and large (more than 5,000 m³/day) plant capacities.

Furthermore, the Kernel System consists of variable driven UF (ultrafiltration)/RO membrane combinations and is designed site-independent. High-grade pre-treatment and the special supervision procedure for the RO membrane characteristics allows a temporary increased production for the optimal use of strong wind periods.

Economic consideration

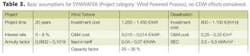

The application of the load management depends strongly on the level of grid tariffs. Beside that, several techno-economic parameters will also affect the most economic configuration and operation of the process load. For broad range of possible SYNWATER projects, the techno-economic parameters are represented in the following table:

Three application fields are presented where – in relation to the average grid tariff at a site over 20 years – the respective application realises the lowest water production costs. For a grid tariff level up to 5 €ct/kWh in general (with an extended range in extreme cases) the conventional grid-connected desalination could be the most economical solution (figure 6 - blue).

Within the prevailing level of medium grid tariffs, ranging from 5 to 12 €ct/kWh (with an extended range in extreme cases), SYNWATER® technology with standard capacities provide desalination at lowest water production costs (figure 6 - rose). For grid tariffs higher than 12 €ct/kWh (with an extended range in extreme cases) it is recommendable to extend the SYNWATER® capacity above the nominal water demand resp. nominal process capacity, see figure 6 (orange).

Currently preparations are underway for the implementation of the first system module described above. Already today wind power offers low and long-term stable costs of energy and therefore is able to compete with large scale conventional power generation. Using wind power directly for energy intensive industrial processes requires an optimised hybrid configuration as well as a balanced load and/or energy management. WWi

References

[1] Käufler, J., 2009, Wind powered electrothermal processes. In: Heat Processing vol. 7, issue 3, (03/09), p. 211-214.

[2] Subiela, V.J., Cartá, J.A. and González, J. 2004, The SDAWES project: lessons learnt from an innovative project. In: Desalination 168, p. 39-47.

[3] Cartá, J.A., González, J. and Subiela, V.J., 2003, Operational analysis of an innovative wind powered reverse osmosis system installed in the Canary Islands. In: Solar Energy 75, p. 153-168.

[4] D. Zejli, R. Benchrifa, A. Bennouna and K. Zazi, 2004. Economic analysis of wind-powered desalination in the south of Marocco. In: Desalination 165, p. 219-230.

[5] Pohl, R., 2008, Entwicklung und Auslegung windbetriebener Membranprozesse., Institut für Energetik und Umwelt gGmbH, Reg. Nr. Inno-Watt051260, Sachbericht 2008.

[6] V. J. Subiela, J. A. de la Fuente, G. Piernavieja and B. Peñate 2009, Canary Islands Institute of Technology (ITC) experiences in desalination with renewable energies (1996–2008). In: Desalination and Water Treatment 7, p. 220-235.

Author's note: Joachim Käufler, Robert Pohl, Hadi Sader are from German company SYNLIFT Systems. For more information on the wind powered SWRO trial, please contact: [email protected], [email protected] and [email protected].

More Water & WasteWater International Archives Issue Articles